Ammonia injection grid for thermal power plant denitration unit

A technology for thermal power plants and ammonia injection grids, applied in the field of ammonia injection grids, can solve problems such as uneven distribution of ammonia, dust accumulation on denitrification catalysts, and large spacing, so as to improve denitrification efficiency, reduce sulfur trioxide conversion, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

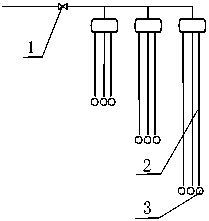

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. But it is not used as any limitation basis for the present invention.

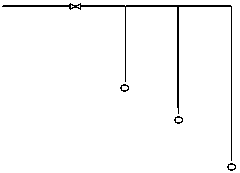

[0013] like figure 2 As shown, an ammonia injection grid used for denitrification devices in thermal power plants includes a valve 1, an ammonia injection branch pipe 2 and an ammonia injection nozzle 3. The valve 1 is arranged on the ammonia injection pipeline, and the pipeline is provided with multiple ammonia injection The branch pipe 2 is connected with an ammonia injection nozzle 3 at its bottom end.

[0014] The present invention redesigns and transforms the branch pipes of the denitrification ammonia injection grille. After the transformation, the number of ammonia injection nozzles is increased from 48 to 144, and the distance between two adjacent ammonia injection branch pipes is reduced from 850mm to 150mm. After the transformation, the number of denitration ammo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com