Metal corrosion tester and application method thereof

A corrosion test and tester technology, applied in weather resistance/light resistance/corrosion resistance, instruments, scientific instruments, etc., can solve the problems of low measurement accuracy, low test efficiency, low operating system, etc., to achieve accurate test data, Achieving a high degree of automation and reducing volatile loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

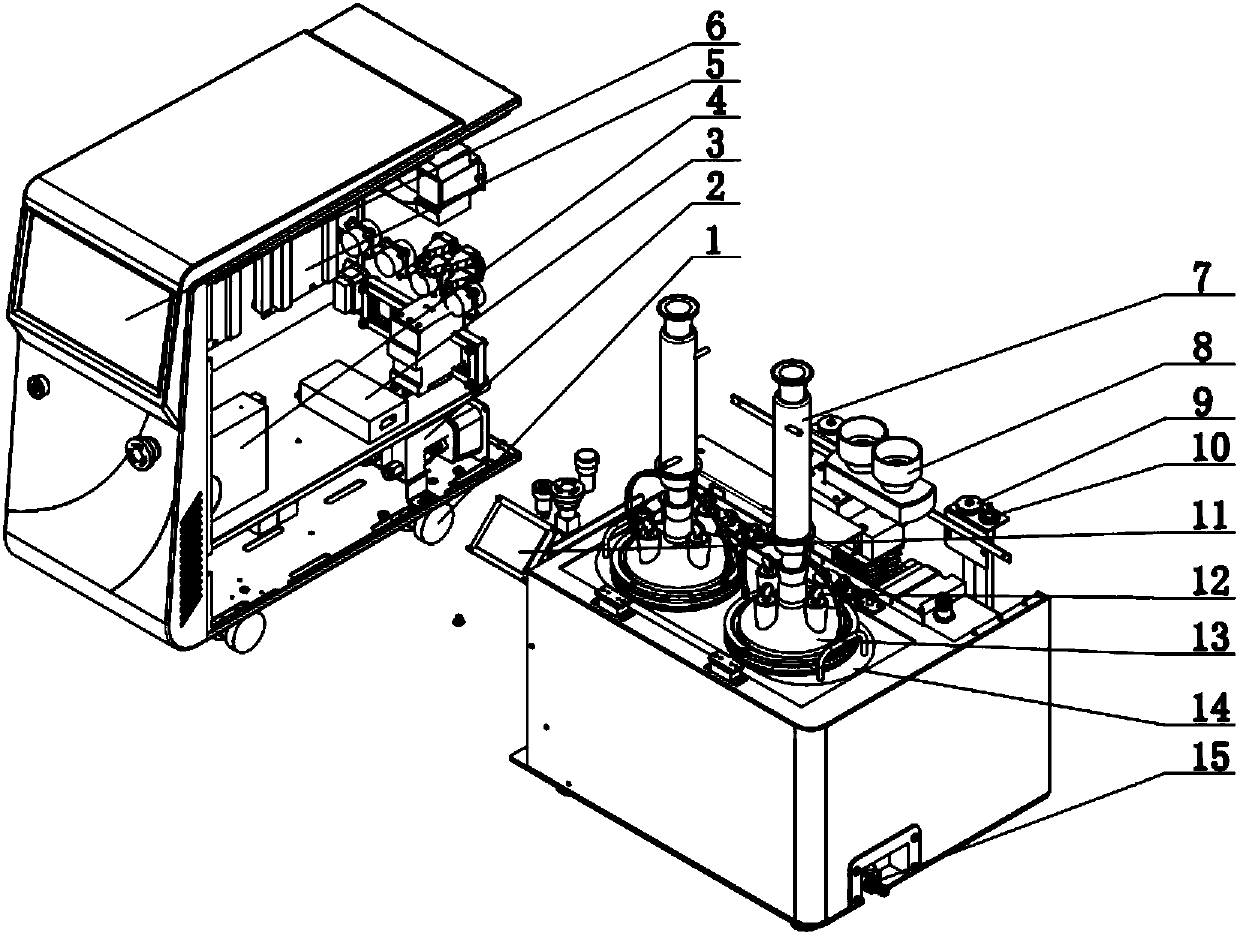

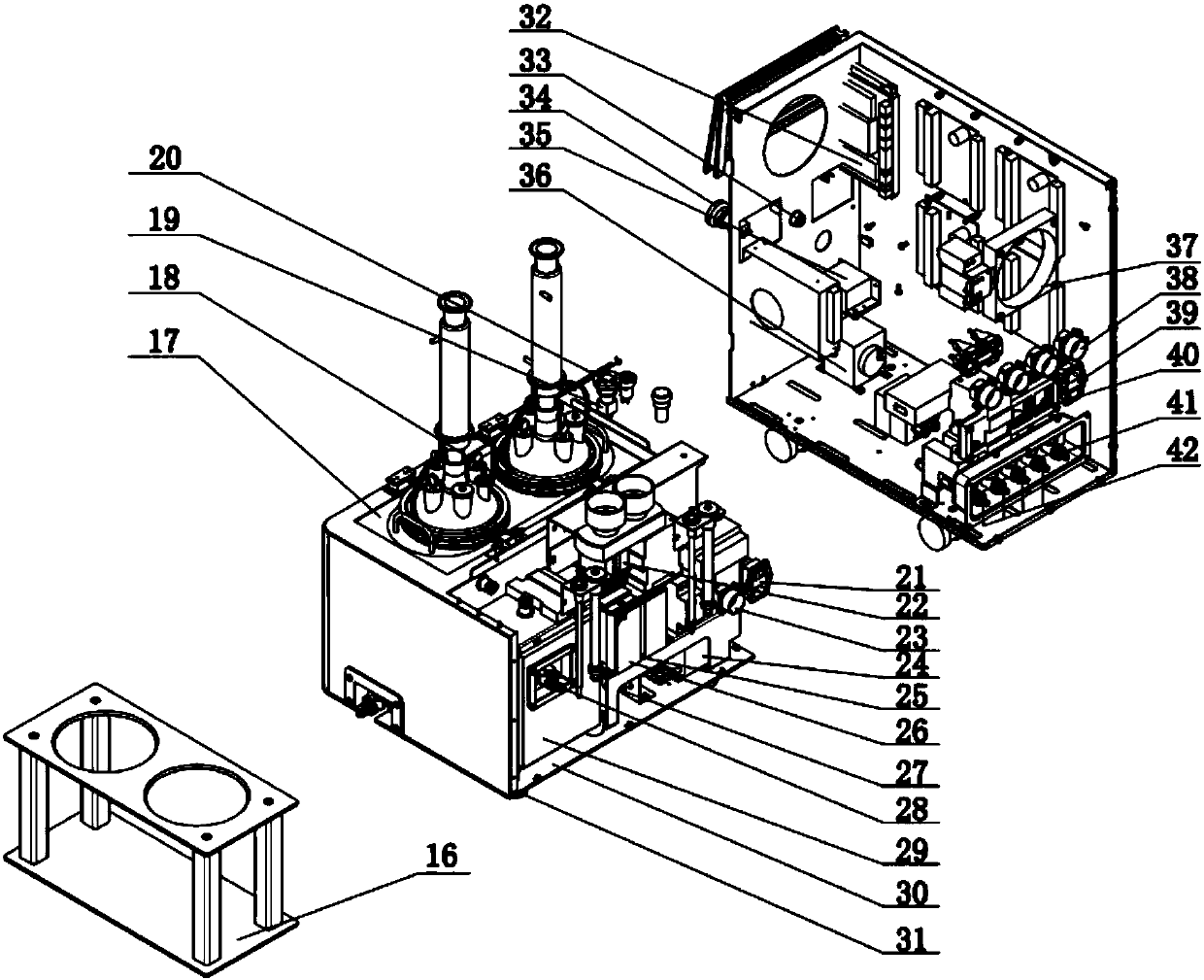

[0027] Such as Figure 1 to Figure 2 As shown, the metal corrosion tester includes a test mechanism, a control mechanism, a sliding mechanism and a tester body.

[0028] The test mechanism includes a constant temperature water tank, a reaction bottle, a reaction bottle cap and a condensation tube. The constant temperature water tank is in the shape of a cuboid, and is provided with a groove suitable for the reaction bottle. The reaction bottle adopts a five-necked reaction bottle, and the five-necked reaction bottle is placed in a constant temperature water tank through a reaction bottle tray. The five-necked reaction bottle is used to place the test solution and the metal sample for the test. The five ports of the five-necked reaction bottle include a middle port and four ports evenly distributed on the periphery, and a condenser tube is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com