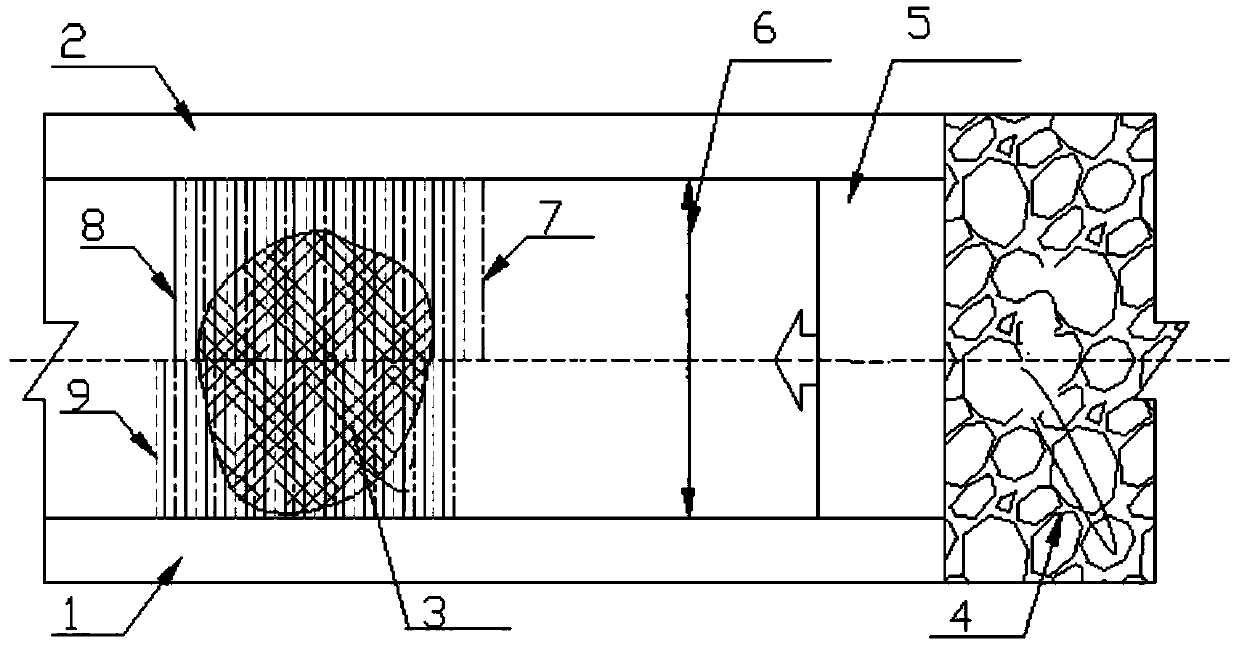

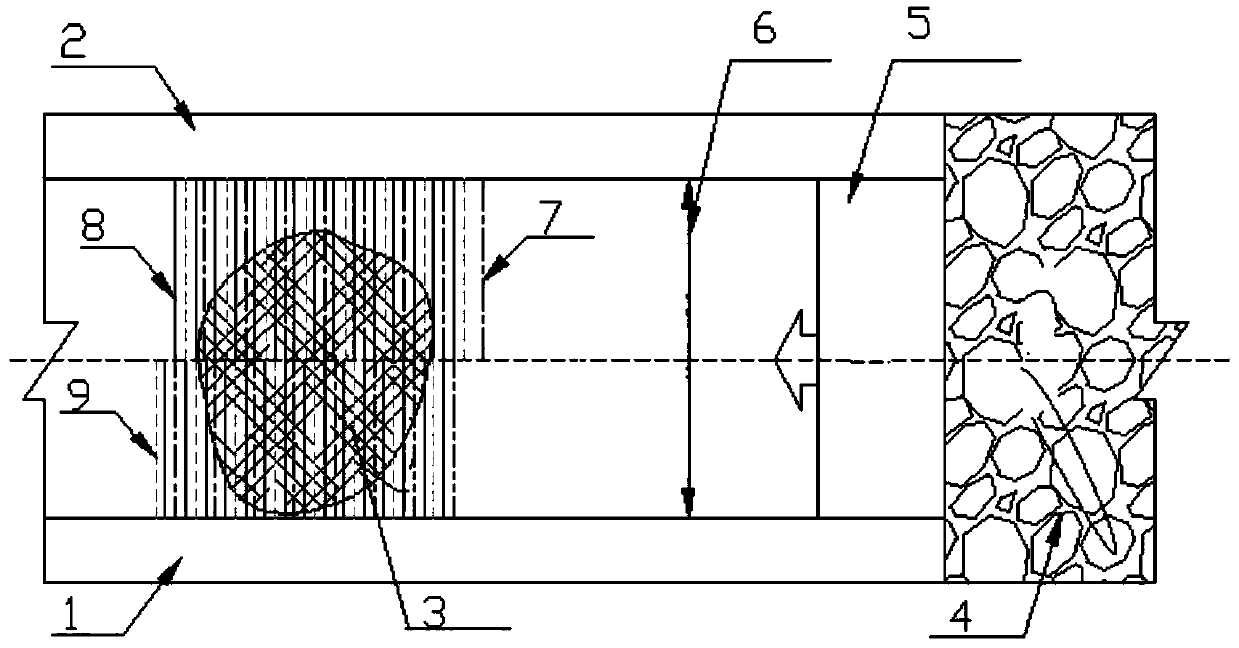

Pre-grouting method for ultra-deep hole and high-pressure two-way roadway in large-scale geological structure fissure coal-rock mass

A geological structure, coal and rock mass technology, applied in the direction of earth drilling, underground chambers, shaft equipment, etc., can solve the problems that affect the stability of coal mining and the incomplete structure of fractured coal and rock mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

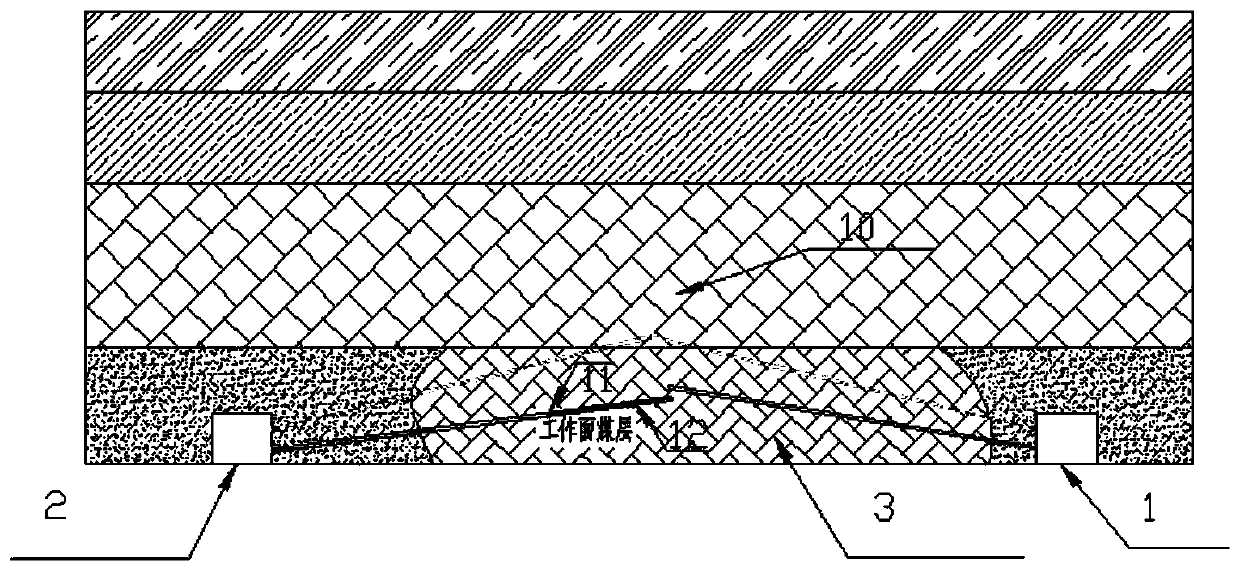

Method used

Image

Examples

example 1

[0044] Example 1: The coal mining face of the coal mine is rectangular, the average thickness of the coal seam is 5.8m, the mining height is 3.0m, including a layer of gangue, and the thickness is 0.34m. The inclination angle of the coal seam in the working face is 0°~7°, and the Platinum hardness of the coal seam is 0.98. The absolute gas emission during the mining face is 39.49m3 / min. There is a large collapse column aXn9 in front of the working face, which is 65.8 meters long in the east-west direction and 35.5 meters long in the north-south direction. Broken, the maximum horizontal principal stress value of the working face test is 12.5MPa, and the maximum horizontal principal stress direction is The minimum horizontal principal stress is 6.95MPa, the vertical principal stress is 9.58MPa, and the maximum horizontal principal stress direction is The average strength of the coal seam is 13.78MPa, and the collapse column will seriously affect the normal mining and equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com