Two-in-one primer glue color sheet and manufacturing method thereof

A two-in-one, primer technology, applied in chemical instruments and methods, adhesives, adhesive types, etc., can solve the problems of high production cost and poor versatility, and achieve lower production costs, fewer layers, and enhanced versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

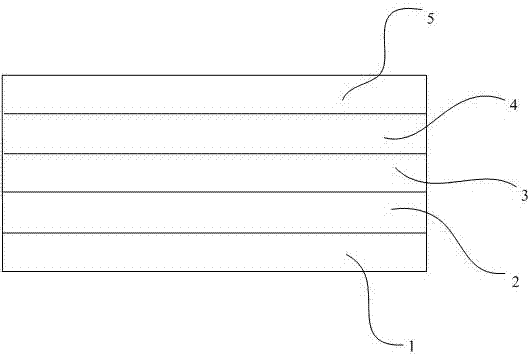

[0048] A two-in-one primer glue watercolor plate, including a back paint layer 1, a substrate 2, a primer glue layer 3, a color film layer 4 and a protective film layer 5, and a formula for the primer glue layer 3 arranged in sequence from bottom to top For: polyester resin 30%, melamine resin 10%, solvent 50%, additive 10%, pigment 5%. The polyester resin is a polyurethane resin, the additive is an isocyanate curing agent, the pigment is a chrome-free pigment, and the solvent is acetone, methyl ethyl ketone, methyl isobutyl ketone, cyclohexanone, isophorone or diacetone alcohol.

[0049] The specific steps of the manufacturing method corresponding to the color plate in the present embodiment are:

[0050]1) Substrate uncoiling: overall line speed: 40-45m / min;

[0051] 2) Substrate pre-treatment: the substrate goes through two degreasing processes, and then undergoes a water washing process and a passivation process;

[0052] 3) Degreasing process: degreasing points: 5-7pt (...

Embodiment 2

[0060] A two-in-one primer glue watercolor plate, including a back paint layer 1, a substrate 2, a primer glue layer 3, a color film layer 4 and a protective film layer 5, and a formula for the primer glue layer 3 arranged in sequence from bottom to top For: polyester resin 40%, melamine resin 5%, solvent 40%, additive 5%, pigment 10%. The polyester resin is a polyurethane resin, the additive is an isocyanate curing agent, the pigment is a chrome-free pigment, and the solvent is acetone, methyl ethyl ketone, methyl isobutyl ketone, cyclohexanone, isophorone or diacetone alcohol.

[0061] The specific steps of the manufacturing method corresponding to the color plate in the present embodiment are:

[0062] 1) Substrate uncoiling: overall line speed: 40-45m / min;

[0063] 2) Substrate pre-treatment: the substrate goes through two degreasing processes, and then undergoes a water washing process and a passivation process;

[0064] 3) Degreasing process: degreasing points: 5-7pt (...

Embodiment 3

[0072] A two-in-one primer glue watercolor plate, including a back paint layer 1, a substrate 2, a primer glue layer 3, a color film layer 4 and a protective film layer 5, and a formula for the primer glue layer 3 arranged in sequence from bottom to top For: polyester resin 35%, melamine resin 8%, solvent 45%, additive 6%, pigment 6%. The polyester resin is a polyurethane resin, the additive is an isocyanate curing agent, the pigment is a chrome-free pigment, and the solvent is acetone, methyl ethyl ketone, methyl isobutyl ketone, cyclohexanone, isophorone or diacetone alcohol.

[0073] The specific steps of the manufacturing method corresponding to the color plate in the present embodiment are:

[0074] 1) Substrate uncoiling: overall line speed: 40-45m / min;

[0075] 2) Substrate pre-treatment: the substrate goes through two degreasing processes, and then undergoes a water washing process and a passivation process;

[0076] 3) Degreasing process: degreasing points: 5-7pt (c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com