Pin welding device and method

A pin and soldering process technology, which is applied in the field of soldering pin devices, can solve problems such as easy oxidation of the soldering point, inability to complete soldering, and long heating time, and achieve the effects of fast speed, easy operation, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

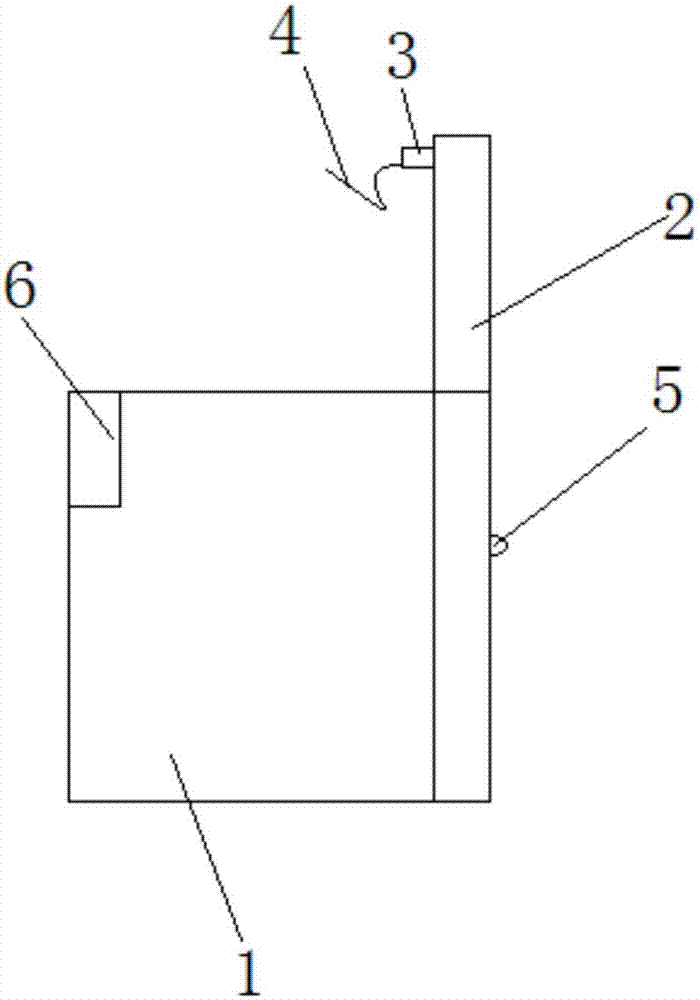

[0025] like figure 1 As shown, a method of soldering pins, in the welding process, put the winding plate with the pins into the device filled with tin liquid, and the lead wire will be controlled by the heater, buzzer, timer and PID controller. The feet and the winding plate are soldered.

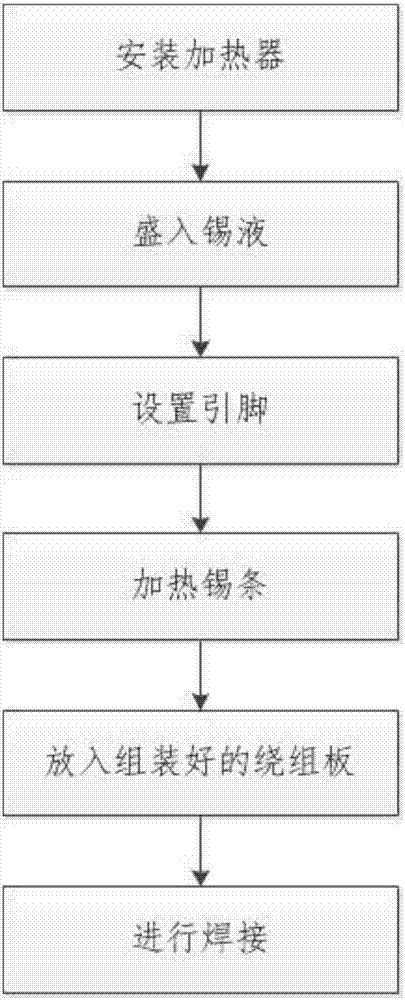

[0026] Based on a device and method for soldering pins, comprising the following steps:

[0027] ①Install the heater and PID controller: put the heater at the bottom of the device to make it heat faster and heat transfer evenly, install the PID controller, buzzer and timer on one side, and connect the heater, buzzer buzzer, timer and PID controller, and then weld the heater, buzzer, timer and PID controller to the device;

[0028] ②Put tin liquid: Put the tin bar into the device, the solid is easy to operate and will not be poured as easily a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com