Method and device for carrying out in-situ remediation on farmland soil polluted by polyaromatic hydrocarbon

A polycyclic aromatic hydrocarbon, in-situ remediation technology, applied in the field of contaminated farmland soil remediation, can solve the problems of high cost, secondary pollution, low efficiency, etc., and achieve the effects of low cost, no secondary pollution, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] According to the ratio of 1g glucose, 10g porous foam iron fine particles and 40ml water, first dissolve glucose in water to make glucose solution, then put the porous foam iron fine particles with a particle size of 200-500 microns into the glucose solution, and make a mixture liquid; the above mixed solution is placed in a hydrothermal reaction kettle, heated at 120°C for 6 hours (the pressure in the hydrothermal reaction kettle is 1.0-2.0MPa), and after the reaction, the fine particles of porous foam iron are taken out and washed with deionized water After drying, the fine particles of carbon-coated porous foam iron can be obtained.

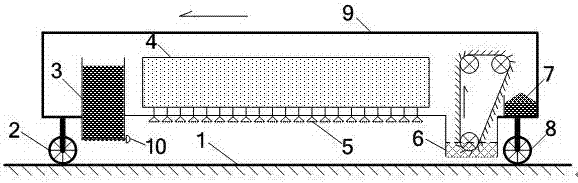

[0034] The charcoal-coated porous iron foam fine particles, sodium perborate and sodium citrate powder are mixed evenly in a ratio of 70:15:15 by mass ratio, and the mixture is made into a mixture hopper 3; the mass concentration is 0.05% Hydrogen peroxide solution is charged in hydrogen peroxide solution storage tank 4.

[0035] Sprin...

Embodiment 2

[0037] According to the ratio of 2.5g glucose, 5g porous foam iron fine particles and 40ml water, glucose is dissolved in water earlier to make glucose solution, then drop into the glucose solution with a particle size of 200-500 micron porous foam iron fine particles to prepare Mixed solution: put the above mixed solution in a hydrothermal reaction kettle, heat at 160°C for 4 hours (the pressure in the hydrothermal reaction kettle is 1.0-2.0MPa), after the reaction, take out the porous foam iron fine particles and wash them with deionized water After drying, the fine particles of carbon-coated porous foam iron are obtained.

[0038] Carbon-coated porous iron foam fine particles, urea peroxide and potassium citrate powder are mixed uniformly in a ratio of 80:10:10 by mass ratio, and the mixture is filled into the mixture hopper 3; the mass concentration is 0.05% Hydrogen peroxide solution is charged in hydrogen peroxide solution storage tank 4.

[0039] Sprinkle the mixture e...

Embodiment 3

[0041] According to the ratio of 2g glucose, 15g porous foam iron fine particles and 40ml water, glucose is dissolved in water earlier to make glucose solution, and then the porous foam iron fine particles with a particle diameter of 200-500 microns are dropped into the glucose solution to form Mixed solution; put the above mixed solution in a hydrothermal reaction kettle, heat at 180°C for 2 hours (the pressure in the hydrothermal reaction kettle is 1.0-2.0MPa), after the reaction, take out the porous foam iron fine particles and wash them with deionized water After drying, the fine particles of carbon-coated porous foam iron are obtained.

[0042] The charcoal-coated porous iron foam fine particles, sodium perborate and sodium citrate powder are mixed evenly in a ratio of 90:5:5 by mass ratio, and the mixture is made into the mixture hopper 3; the mass concentration is 0.05% Hydrogen peroxide solution is charged in hydrogen peroxide solution storage tank 4.

[0043] Sprinkl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com