High hardness, high thermal conductivity and low expansion coefficient Al-Cu-CNT material and preparation method thereof

A technology with low expansion coefficient and high thermal conductivity, applied in the field of materials, can solve the problems of poor overall performance of Al-Cu materials, and achieve the effects of excellent economy, easy realization and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

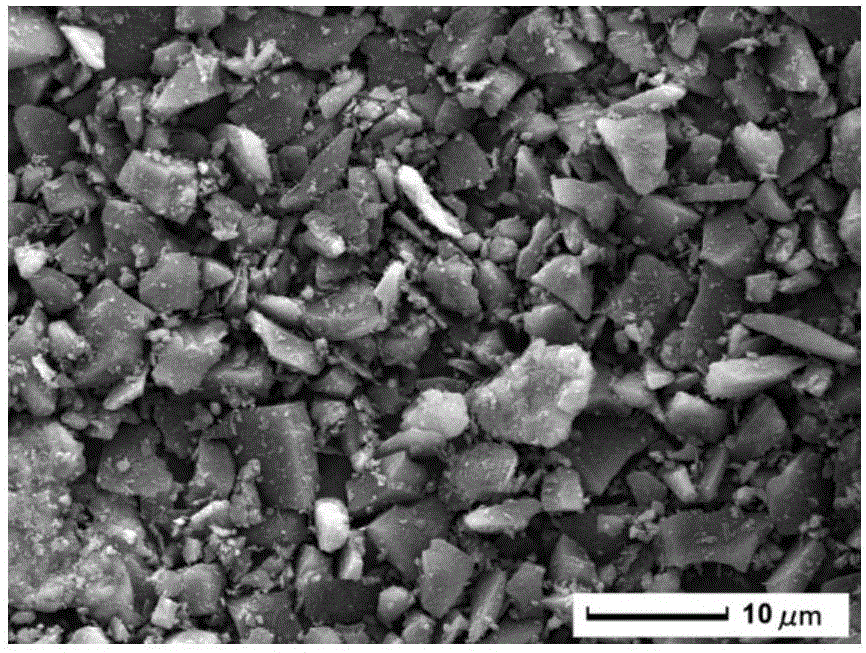

[0034] Such as figure 1 , 3 , 5 shown.

[0035] A kind of preparation method of Al-4Cu material:

[0036] First, prepare 40 g of Al and Cu single substance mixed powder, including 96wt.% (38.4 g) of Al powder and 4wt.% (1.6 g) of Cu powder, put the mixed powder in a beaker and stir evenly, and place it in a drying box Dry at 100°C for 1 hour;

[0037] Secondly, first weigh 160 g of agate balls and place them in a 500 ml nylon ball mill jar according to the ball-to-material ratio of 4:1, then place the dried and uniformly mixed powder in the nylon ball mill jar, and seal it with a cover;

[0038] Then, install the ball mill jar on the planetary ball mill, start the ball mill, set the ball mill parameters to 250 r / min, stop the ball mill for 60 minutes and stop for 10 minutes, and take out the powder in the ball mill jar after grinding for 24 hours;

[0039] Afterwards, the obtained powder is packed into a mold with a diameter of 30mm, and pressed on a 100t four-column hydra...

Embodiment 2

[0044] Such as figure 2 , 4 , 6 shown.

[0045] A kind of preparation method of Al-4Cu-0.5CNT material:

[0046] This example is similar to Example 1, except that CNT is added, including Al powder 95.5wt.% (38.2 g), Cu powder 4wt.% (1.6 g), and CNT 0.5wt.% (0.2 g);

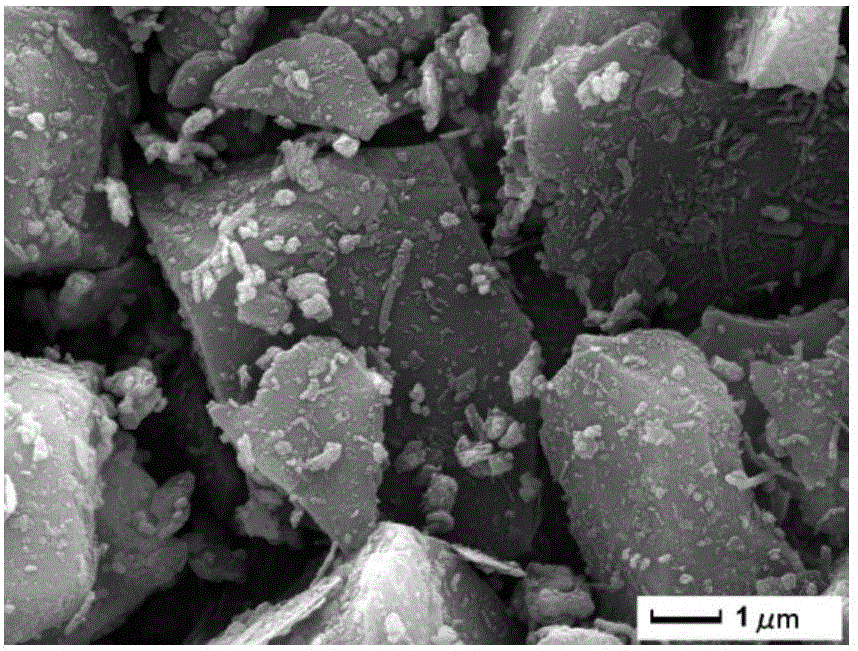

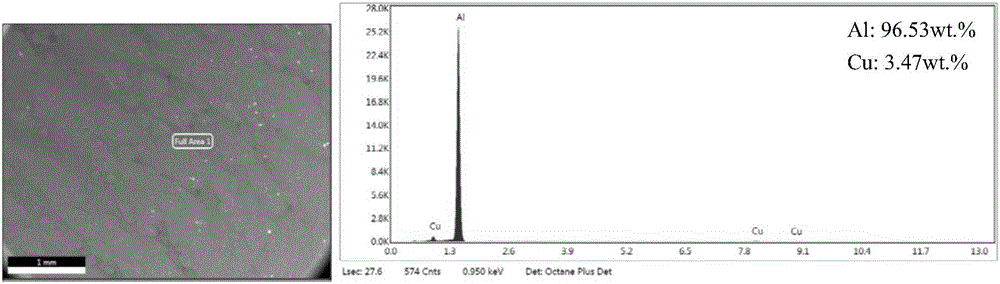

[0047] figure 1 It is the morphology diagram of Al-4Cu-0.5CNT after ball milling. It can be seen that CNT is mechanically alloyed with Al and Cu, which can significantly reduce the thermal expansion coefficient of the material and further improve the thermal conductivity of the material; Figure 4 and Figure 6They are the topography and EDS analysis before and after heat treatment, respectively. From the SEM-EDS analysis, the composition of the material is consistent with the preset concept, which can effectively guarantee the performance of the material; Table 1 has Al-4Cu-0.5 The hardness value of the CNT material was analyzed and found that the addition of CNT did not reduce the hardness of the material,...

Embodiment 3

[0051] A preparation method of Al-2.8Cu-0.7CNT material:

[0052] First, prepare 40 g of mixed powder of Al, Cu and CNT, including 96.5wt.% (38.6 g) of Al powder, 2.8wt.% (1.12 g) of Cu powder, and 0.7wt.% (0.28 g) of CNT. Stir in a beaker evenly, and dry in a drying oven at 120°C for 1.5 hours;

[0053] Secondly, first weigh 120 g of agate balls and place them in a 500 ml nylon ball mill jar according to the ball-to-material ratio of 3:1, then place the dried and uniformly mixed powder in the nylon ball mill jar, and seal it with a cover;

[0054] Then, install the ball milling tank on the planetary ball mill, start the ball milling, set the ball milling parameters to 200 r / min, stop the ball milling for 60 minutes for 15 minutes, and take out the powder in the ball milling tank after 24 hours of ball milling;

[0055] Afterwards, the obtained powder is packed into a mold with a diameter of 25mm, and pressed on a 100t four-column hydraulic press to obtain a round block with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com