Organic porous integral material and preparation method and application thereof

A monolithic material and organic technology, applied in the field of organic porous monolithic materials and their preparation and application, can solve the problems of pH sensitivity, difficult control of free radical polymerization rate, cumbersome process, etc., achieve strong hydrophobicity, simple functional modification method, good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

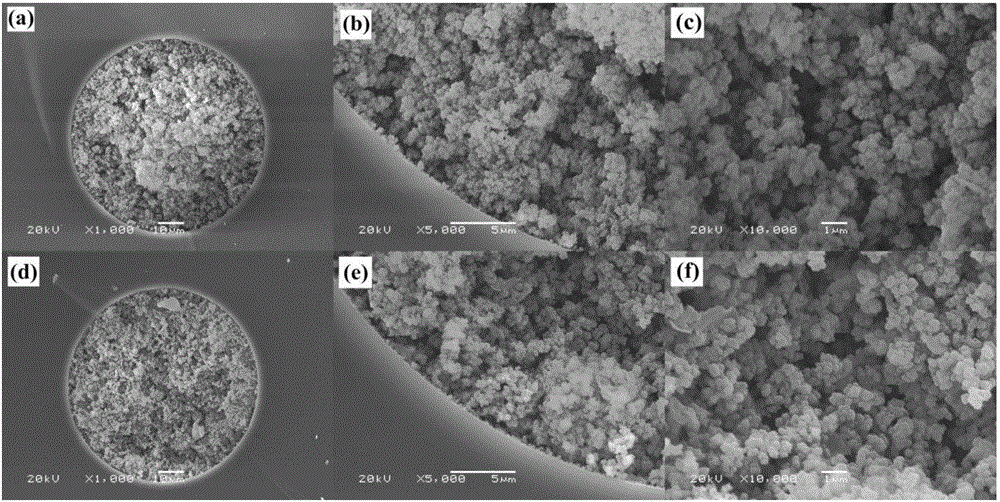

Embodiment 1

[0050] 1) Add 30 mg of DPEPA reagent to a UV transparent centrifuge tube.

[0051] 2) Add 8 mg of functional monomer NDM to the above-mentioned UV transparent centrifuge tube.

[0052] 3) Add 125 μL of n-butanol and 15 μL of ethylene glycol to the above-mentioned UV transparent centrifuge tube.

[0053] 4) Add 0.1 mg of photoinitiator to the above-mentioned ultraviolet transparent centrifuge tube.

[0054] 5) Ultrasonic the above-mentioned centrifuge tube for 5 minutes to mix the various components therein evenly, and remove the dissolved oxygen dissolved therein.

[0055] 6) Introduce 1 μL of the prepolymer solution obtained in step 5) into a 75 μm (inner diameter) UV-transparent capillary tube that has been activated with 3-(trimethoxysilyl)propyl methacrylate in advance with a syringe, and then the capillary Both ends were sealed with silica gel, and then the UV transparent centrifuge tube containing the remaining mixed solution was sealed.

[0056] 7) Place the UV trans...

Embodiment 2

[0059] 1) Add 30 mg of DPEPA reagent to a UV transparent centrifuge tube.

[0060] 2) Add 16 mg of functional monomer NDM to the above-mentioned UV transparent centrifuge tube.

[0061] 3) Add 125 μL of n-butanol and 15 μL of ethylene glycol to the above-mentioned UV transparent centrifuge tube.

[0062] 4) Add 0.1 mg of photoinitiator to the above-mentioned ultraviolet transparent centrifuge tube.

[0063] 5) Ultrasonic the above-mentioned centrifuge tube for 5 minutes to mix the various components therein evenly, and remove the dissolved oxygen dissolved therein.

[0064] 6) Introduce 1 μL of the prepolymer solution obtained in step 5) into a 75 μm (inner diameter) UV-transparent capillary tube that has been activated with 3-(trimethoxysilyl)propyl methacrylate in advance with a syringe, and then the capillary Both ends were sealed with silica gel, and then the UV transparent centrifuge tube containing the remaining mixed solution was sealed.

[0065] 7) Place the UV tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com