Water purifying agent with defect-rich carbon carriers and immobilized microorganisms and method for preparing water purifying agent

A carbon carrier, defect-rich technology, which is applied in biological water/sewage treatment, granular microbial carrier treatment, chemical instruments and methods, etc. , difficult electrostatic interaction and other problems, to achieve the effect of improving the adsorption and fixation efficiency, overcoming the hydrophobicity problem and improving the adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of the water purifying agent of rich defect carbon carrier immobilized microorganism, concrete steps are:

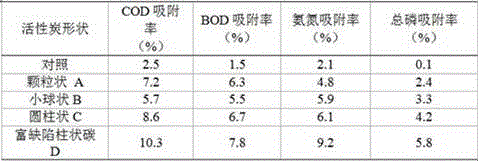

[0031] 1. Preparation of carbon supports with hydrophilic functional groups and defects on the surface

[0032] 1) Put NaOH+KOH=90g (NaOH:KOH=46.5:43.5, mass ratio) in a 200 ml reactor liner and melt at 165°C for 2 hours to obtain clarified molten lye;

[0033] 2) Using glucose and urea as raw materials, add them to clarified molten lye and react for 12 hours to generate defect-rich powder carbon precursor material A;

[0034] 3) Wash the above-mentioned carbon precursor A with water until the pH value of the washing solution is about 7, remove water-soluble impurities, and then centrifuge to obtain the lower precipitate; the lower precipitate is then washed with absolute ethanol to remove water-insoluble organic impurities, and finally centrifuged The precipitate was dried overnight at 80°C to obtain defect-rich powdery carbon precur...

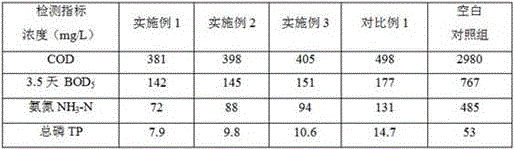

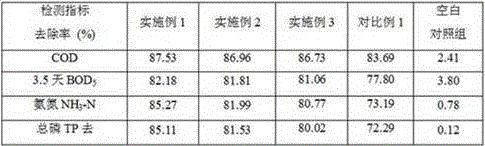

Embodiment 1

[0039] A kind of preparation method of the water purifying agent of rich defect carbon carrier immobilized microorganism, concrete steps are:

[0040] (1) Preparation of carbon supports with hydrophilic functional groups and defects on the surface

[0041] 1) Put NaOH+KOH=90g (NaOH:KOH=46.5:43.5, mass ratio) in a 200 ml reactor liner and melt at 165°C for 2 hours to obtain clarified molten lye;

[0042] 2) Using glucose and urea as raw materials, add them to clarified molten lye and react for 12 hours to generate defect-rich powder carbon precursor material A;

[0043] 3) Wash the above-mentioned carbon precursor A with water until the pH value of the washing solution is about 7, remove water-soluble impurities, and then centrifuge to obtain the lower precipitate; the lower precipitate is then washed with absolute ethanol to remove water-insoluble organic impurities, and finally centrifuged The precipitate was dried overnight at 80°C to obtain defect-rich powdery carbon precu...

Embodiment 2

[0048] A kind of preparation method of the water purifying agent of rich defect carbon carrier immobilized microorganism, concrete steps are:

[0049] (1) Preparation of carbon supports with hydrophilic functional groups and defects on the surface

[0050] 1) Put NaOH+KOH=90g (NaOH:KOH=46.5:43.5, mass ratio) in a 200 ml reactor liner and melt at 180°C for 2 hours to obtain clarified molten lye;

[0051] 2) Using glucose and urea as raw materials, add them to clarified molten lye and react for 10 hours to generate defect-rich powder carbon precursor material A;

[0052] 3) Wash the above-mentioned carbon precursor A with water until the pH value of the washing solution is about 7, remove water-soluble impurities, and then centrifuge to obtain the lower precipitate; the lower precipitate is then washed with absolute ethanol to remove water-insoluble organic impurities, and finally centrifuged The precipitate was dried overnight at 80°C to obtain defect-rich powdery carbon precu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com