Magnetic arsenic adsorbent and its preparation method and application

An adsorbent and magnetic technology, applied in the field of magnetic arsenic adsorbent and its preparation, can solve problems such as low adsorption capacity, secondary pollution, and large-scale wastewater that limit industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

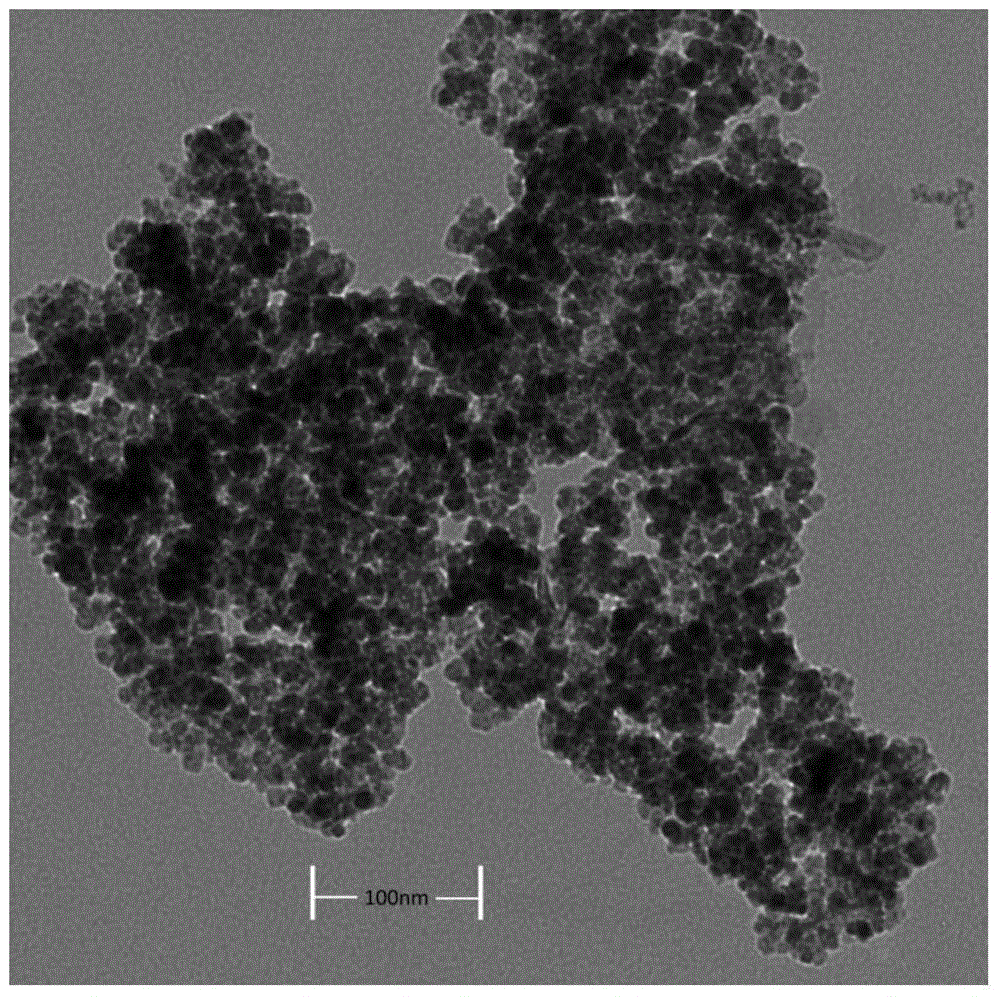

[0043] 1) Preparation of magnetic nanoparticles

[0044] 2mmol of FeCl 3 , 1mmol of FeCl 2 Mix 5ml of NaOH aqueous solution with a pH value mutation agent with a concentration of 3.75mol / L in 30ml of solvent water at a speed of 1000rmp, and carry out a co-precipitation reaction at room temperature for 15 minutes. After the reaction is completed, use a magnet to absorb the reaction product. Separation, washing with deionized water for 5 times, the amount of water used for washing is 100ml, to obtain magnetic nanoparticles, and the yield of the obtained product is 98.2%.

[0045] The particle diameter of the magnetic nanoparticles is 12 nm.

[0046] 2) Preparation of magnetic arsenic adsorbent

[0047] Add 1.5 g of magnetic nanoparticles obtained in step 1) to FeCl with a concentration of 0.3 mol / L 2 In 1L of aqueous solution, stir and mix evenly at the speed of 1000rmp, add NaOH aqueous solution with a concentration of 3.75mol / L to adjust the pH value to 8, and carry out em...

Embodiment 2

[0050] 1) Preparation of magnetic nanoparticles

[0051] 10mmol of FeCl 3 , 5mmol of FeCl 2Mix with 20ml of NaOH aqueous solution of pH mutation agent with a concentration of 3.75mol / L in 200ml of solvent water under the condition of rotating speed of 1000rmp and carry out co-precipitation reaction at room temperature for 15 minutes. Separation and washing with deionized water for 5 times, the volume ratio of the water used for each washing to the reaction system was 1:12 to obtain magnetic nanoparticles, and the yield of the obtained product was 96.8%.

[0052] 2) Preparation of magnetic arsenic adsorbent

[0053] Add 1 g of magnetic nanoparticles obtained in step 1) to Fe(NO 3 ) 2 In the 0.6L aqueous solution, stir and mix evenly at the speed of 1000rmp, add NaOH aqueous solution with a concentration of 3.75mol / L to adjust the pH value to 10, and carry out the embedding reaction at 30°C for 10 minutes, and then add the mass percent concentration 90ml of 40% oxidant hydr...

Embodiment 3

[0055] 1) Preparation of magnetic nanoparticles

[0056] 20mmol of FeCl 3 , 10mmol of FeCl 2 Mix 50ml of NaOH aqueous solution with a pH value mutation agent with a concentration of 3.75mol / L in 300ml of solvent water under the condition of a rotation speed of 1000rmp, and carry out co-precipitation reaction at room temperature for 15 minutes. After the reaction is completed, use a magnet to absorb the reaction product. Separation and washing with deionized water for 5 times, the volume ratio of the water used for each washing to the reaction system was 1:12 to obtain magnetic nanoparticles with a yield of 99.3%.

[0057] The particle size of the magnetic nanoparticles is 12 nm.

[0058] 2) Preparation of magnetic arsenic adsorbent

[0059] Add 1 g of magnetic nanoparticles obtained in step 1) to FeSO with a concentration of 0.3 mol / L 4 In the 0.6L aqueous solution, stir and mix evenly at the speed of 1000rmp, add NaOH aqueous solution with a concentration of 3.75mol / L to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com