Preparation method of one-dimensional nanowire type lithium manganate positive electrode material

A linear lithium manganate, cathode material technology, applied in the direction of positive electrode, nanotechnology, nanotechnology, etc., can solve the problems of poor rate performance, poor cycle performance, etc., achieve good discharge performance, easy operation, and increase the contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

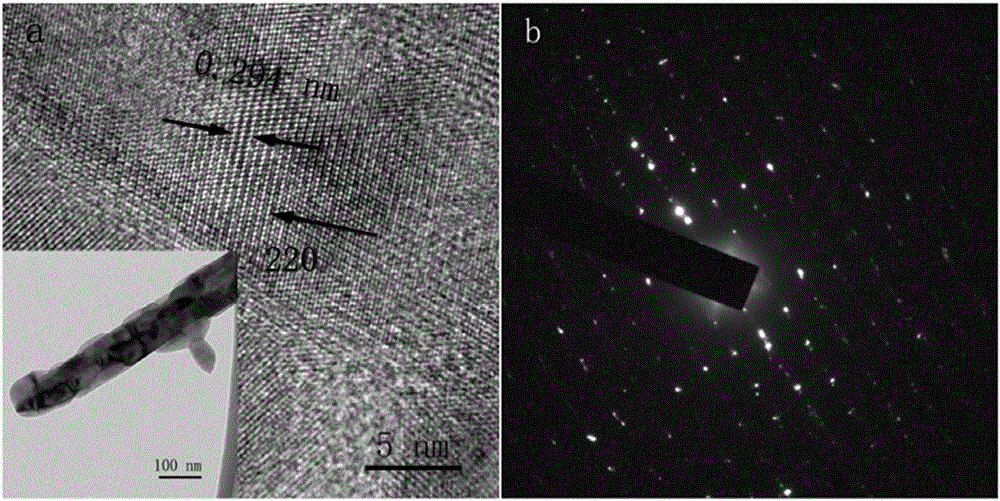

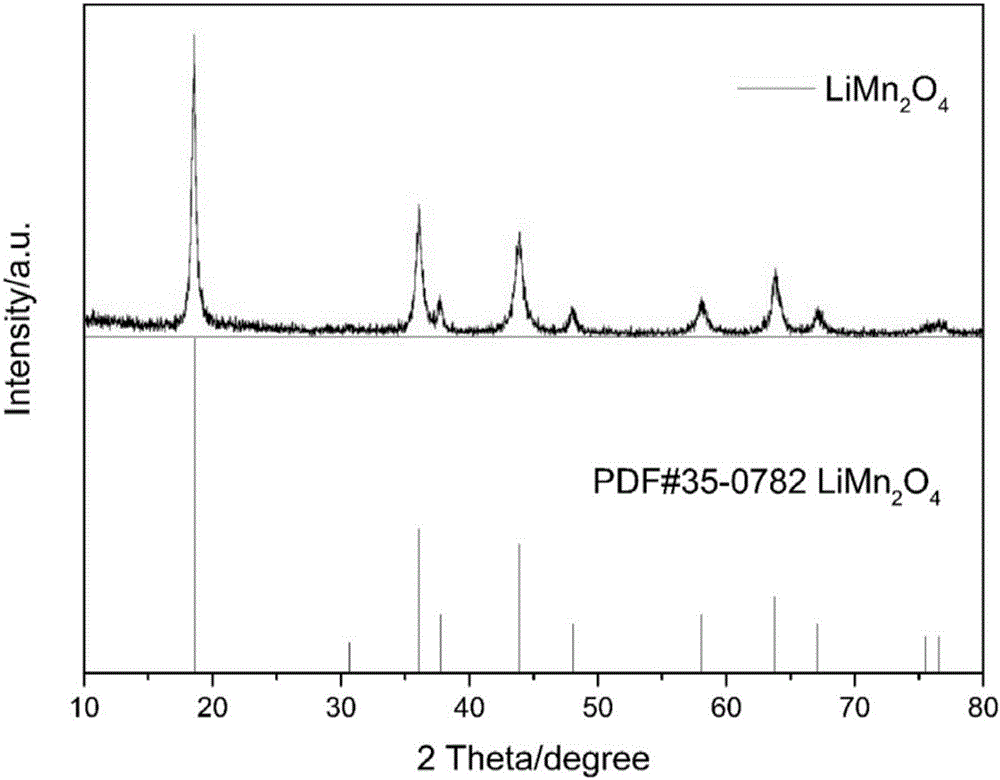

[0031] Weigh Mn(CH 3 COO) 2 4H 2 O, (NH 4 ) 2 S 2 o 8 and (NH4) 2 SO 4 and added to a 100mL beaker. Then add 60 mL of deionized water to the beaker, place the beaker on a stirrer and stir for two minutes to completely dissolve the solids. The homogeneously mixed solution was transferred to a 100mL reaction kettle. Tighten the reaction kettle and put it into an electric blast drying oven, set it at 140°C, and heat it for 12 hours to obtain nanowire-shaped α-MnO 2 . and the obtained α-MnO 2 Wash and dry in deionized water and ethanol solution respectively (100°C, 12h). The prepared α-MnO was washed alternately with deionized water and absolute ethanol for 6 times. 2 , Centrifuge the mixed suspension with a centrifuge, and suck up the waste liquid with a pipette. After washing, the samples were dried in an electric blast drying oven (60 °C, 10 h). The dried α-MnO 2 Grind for 5min. Weigh lithium hydroxide monohydrate and α-MnO according to the molar ratio of 1:2 ...

Embodiment 2

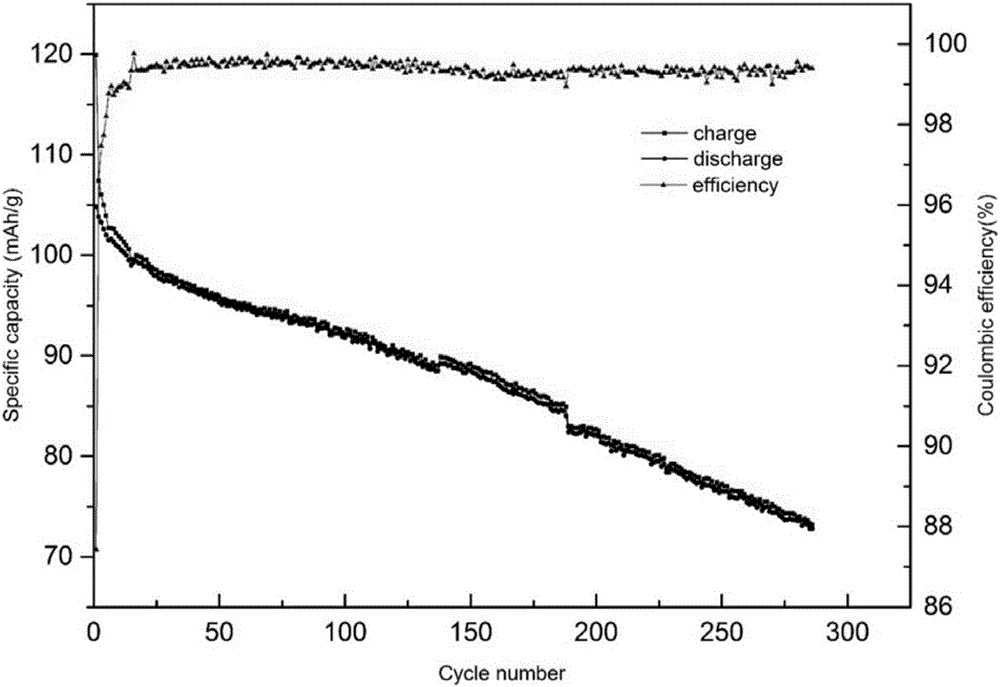

[0036]In this embodiment, when the prepared nanowire-type lithium manganese oxide is applied to a lithium-ion battery, the lithium-ion battery includes a negative electrode of the battery, an electrolyte, and a positive electrode of the battery;

[0037] When preparing the positive electrode sheet, lithium manganate, conductive agent A is super-p acetylene black, conductive agent B is carbon nanotube, binder is PVDF (polyvinylidene fluoride), by mass percentage: positive electrode active material 92%, conductive Agent A3%, conducting agent B1%, binding agent 4% are equipped with each composition (positive electrode active material+conducting agent A+conducting agent B+binding agent=100%);

[0038] When preparing the negative electrode sheet, commercial graphite was used as the active material, and the conductive agent was super-p acetylene black, in terms of mass percentage: 96% of commercial graphite and 4% of super-p acetylene black.

[0039] Electrolyte solvent is EC, DEC, ...

Embodiment 3

[0041] In this embodiment, when the prepared nanowire-type lithium manganese oxide is applied to a lithium-ion battery, the lithium-ion battery includes a negative electrode of the battery, an electrolyte, and a positive electrode of the battery;

[0042] When preparing the positive electrode sheet, lithium manganate, conductive agent A is super-p acetylene black, conductive agent B is carbon nanotubes, and binder is PVDF (polyvinylidene fluoride), by mass percentage: positive electrode active material 94%, conductive 3.5% of agent A, 1% of conductive agent B, and 1.5% of binding agent are prepared to form each composition (positive electrode active material+conducting agent A+conducting agent B+binding agent=100%);

[0043] When preparing the negative electrode sheet, commercial graphite is used as the active material, and the conductive agent is super-p acetylene black, in terms of mass percentage: 97% of commercial graphite and 3% of super-p acetylene black.

[0044] The el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com