A kind of solder preform containing flux and preparation method thereof

A flux and pre-forming technology, applied in welding equipment, welding/cutting media/materials, manufacturing tools, etc., can solve the problems of difficult control of flux content, easy damage to the flux layer, and flux spatter, to avoid Flux residue, uniformity is easy to control, and the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the solder preform containing flux in the present embodiment is as follows:

[0035] Step 1) prepare the material ingot of soldering flux and molten solder, for subsequent use;

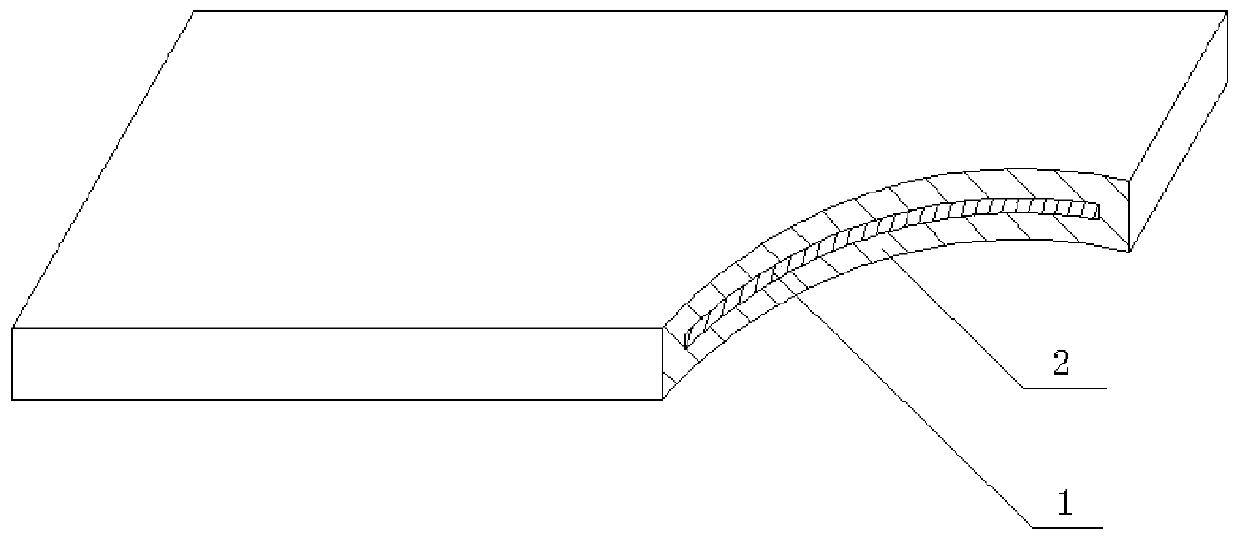

[0036] Step 2) Add the flux prepared in step 1 to the inside of the ingot, wherein the mass percentage of solder is 99.2%, and the mass percentage of flux is 0.8%, and the ingot is extruded to contain a single layer of flux on the stock (eg figure 1 shown);

[0037] Step 3) rolling the billet into a material strip containing a single layer of flux with a required thickness;

[0038] Step 4) Cutting the strip into desired shapes of solder preforms.

Embodiment 2

[0040] The preparation method of the solder preform containing flux in the present embodiment is as follows:

[0041] Step 1) prepare the material ingot of soldering flux and molten solder, for subsequent use;

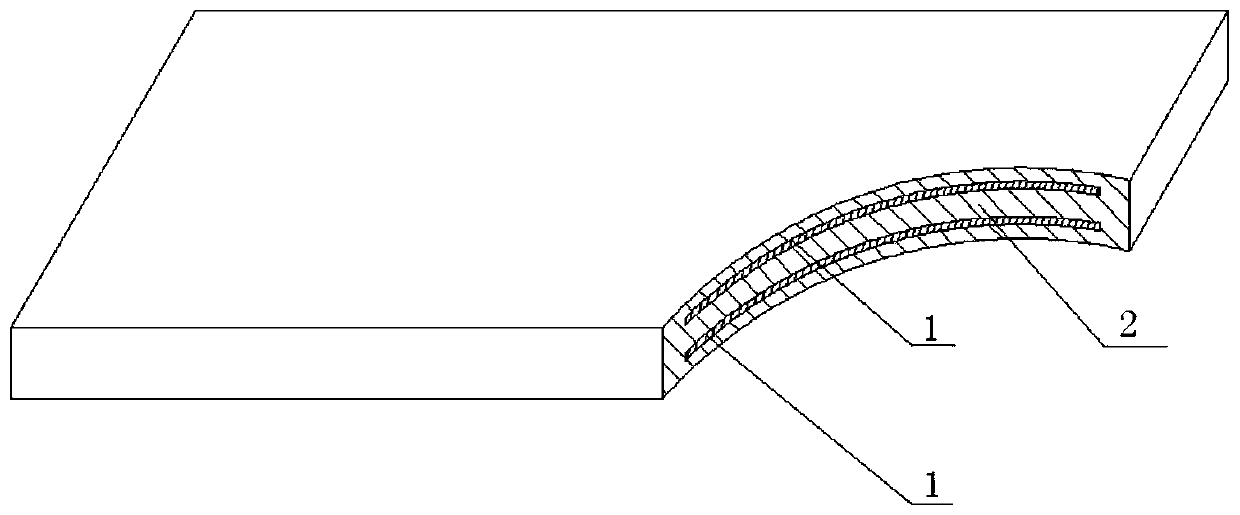

[0042] Step 2) Add the soldering flux prepared in step 1 to the inside of the ingot, wherein the mass percentage of solder is 99%, and the mass percentage of flux is 1%, and the ingot is extruded to contain double layer of flux on the stock (eg figure 2 shown);

[0043] Step 3) Rolling the billet into a material strip containing double-layer flux of required thickness;

[0044] Step 4) Cutting the strip into desired shapes of solder preforms.

Embodiment 3

[0046] The preparation method of the solder preform containing flux in the present embodiment is as follows:

[0047] Step 1) prepare the material ingot of soldering flux and molten solder, for subsequent use;

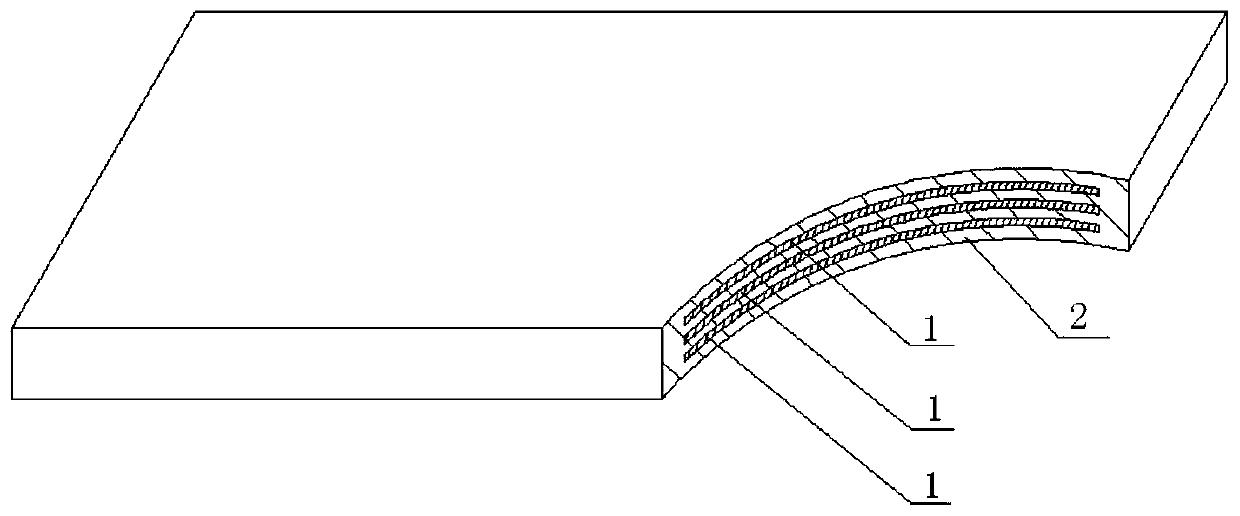

[0048] Step 2) Add the flux prepared in step 1 to the inside of the ingot, wherein the mass percentage of solder is 95%, and the mass percentage of flux is 5%, and the ingot is extruded to contain three layer of flux on the stock (eg image 3 shown);

[0049] Step 3) Rolling the billet into a strip of required thickness containing three layers of flux;

[0050] Step 4) Cutting the strip into desired shapes of solder preforms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com