Preparing method and structure for cookware with lotus effect surface

A technology of lotus effect and cooking utensils, which is applied in the direction of nanotechnology, nanotechnology, coating, etc. for materials and surface science, and can solve the problems of non-stick property decline and easy volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

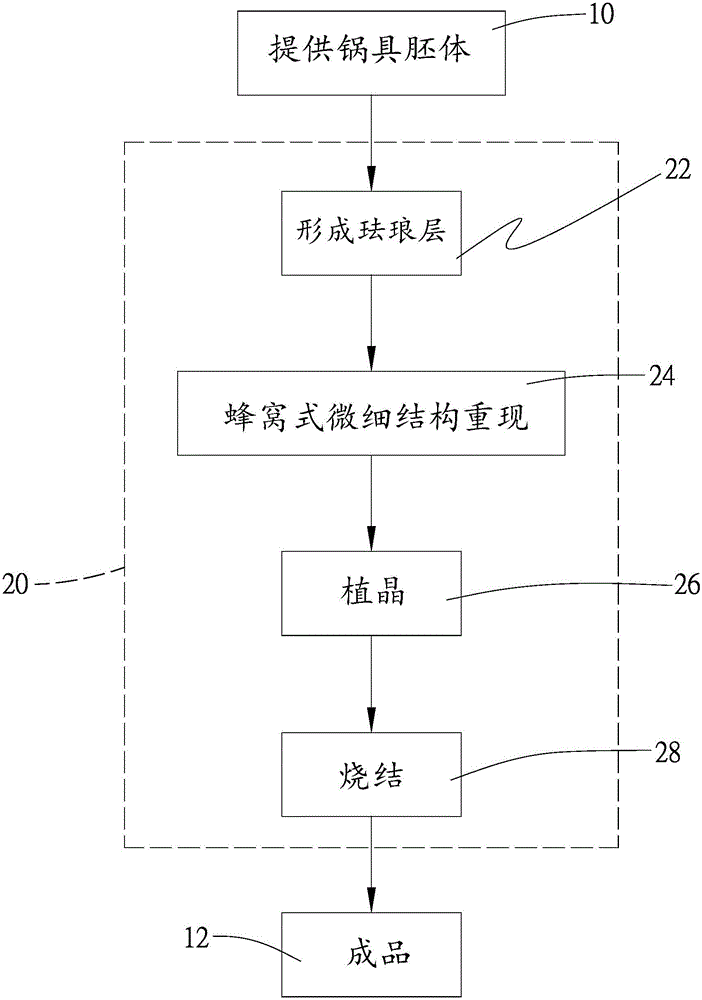

[0028] exist figure 1 In it, it is clarified that the preparation method of the pot with lotus effect surface in the present invention is to add the process of "surface treatment 20" between the two steps of "providing the pot embryo body 10" and "finished product 12", so as to realize the pot having the lotus effect surface.

[0029] In the step of "providing the pot embryo body 10", the required pot embryo body 30 can be purchased, such as figure 2 . Of course, the self-made pot embryo body 30 is also one of the options.

[0030] exist figure 1 Among them, the "surface treatment 20" step covers: "formation of enamel layer 22", "reproduction of honeycomb microstructure 24", "planting crystal 26" and "sintering 28", so that the pot embryo has a lotus effect surface. Next, match Figure 3 ~ Figure 5 Make a detailed statement.

[0031] Such as figure 1 , image 3 As shown, in the step of "forming the enamel layer 22", one of spraying and enamelling techniques is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com