Sandwich-structured nano-adsorbent of carbon-coated magnesium oxide and preparation method thereof

A carbon-coated magnesium oxide, nano-adsorption technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of low adsorption rate, difficult collection of nano-MgO, hindering the process of industrial application, etc. , to achieve the effect of strong adsorption capacity, long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

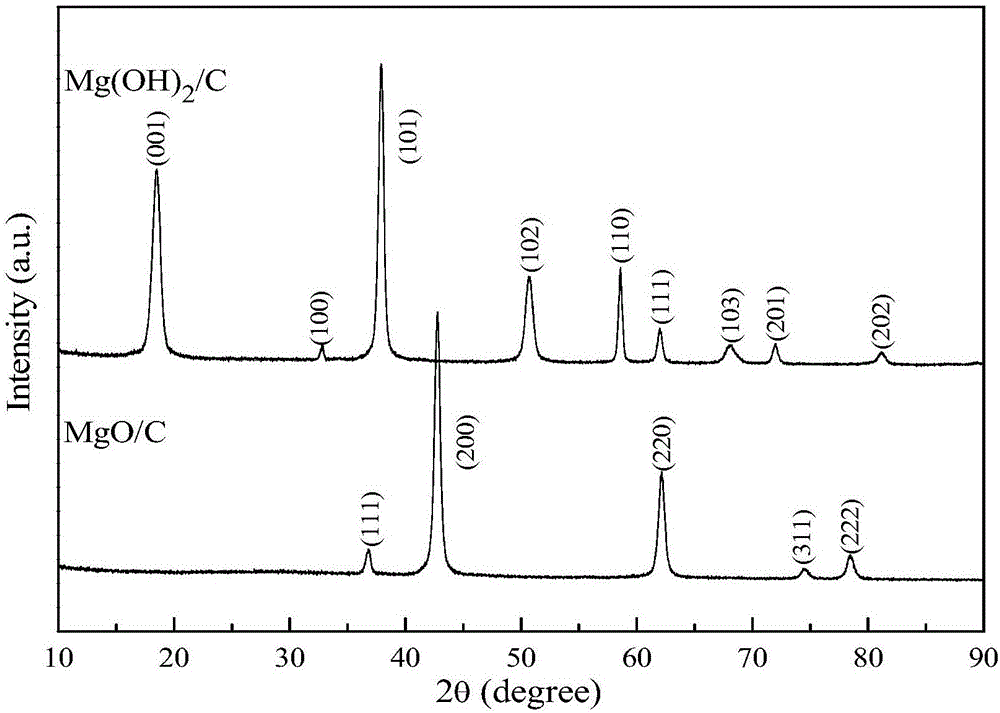

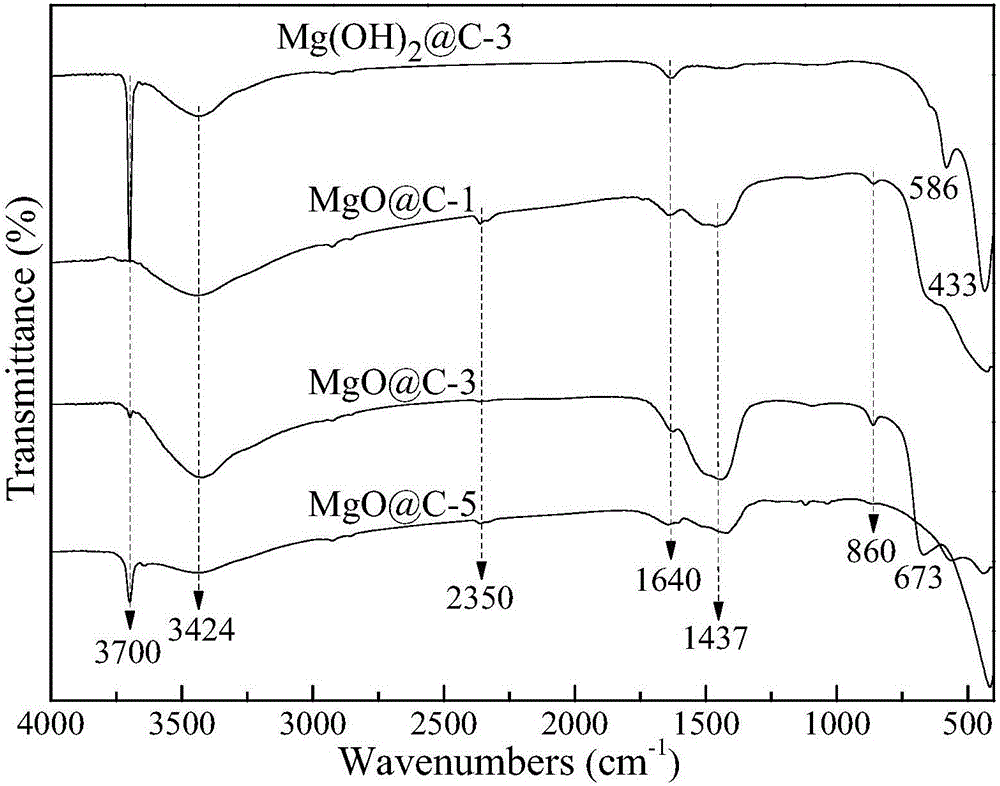

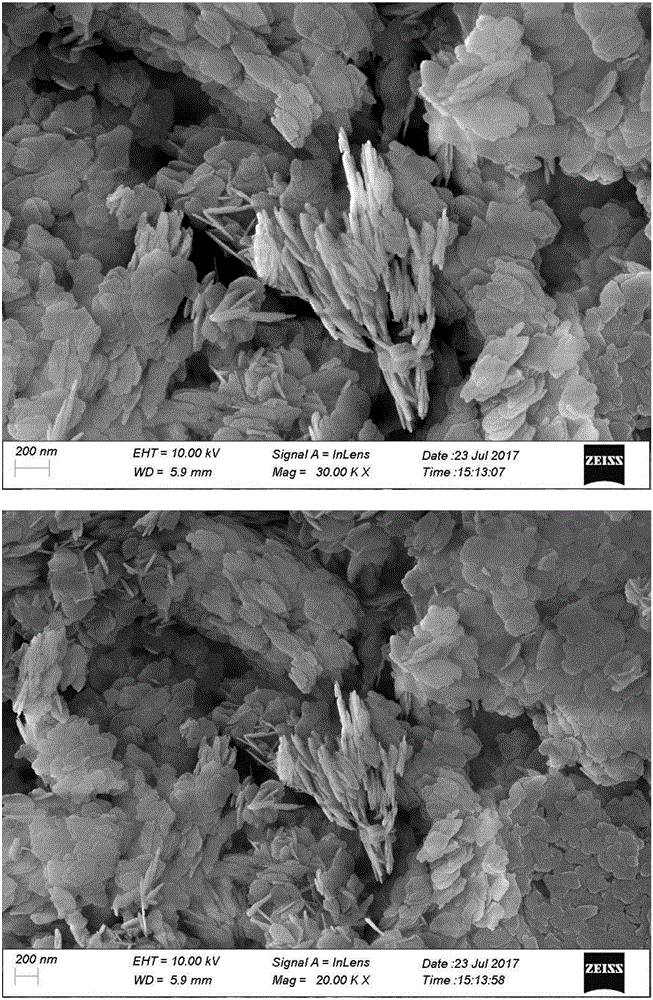

Embodiment 1

[0032] Weigh 5.1g of magnesium chloride hexahydrate, 1.23g of glucose monohydrate, and 1.0g of polyvinylpyrrolidone (Mw=58000) into 100mL of 50% ethanol solution, and stir at a constant temperature of 25°C and a stirring speed of 500r / min for 20min to form a magnesium salt solution. 5mL ammonia water (analytical grade, NH 3 content of 15%-28%) was added to the magnesium salt solution at a constant speed, and stirred at a constant temperature for 120 minutes at a temperature of 25° C. and a stirring speed of 450 r / min to form a magnesium salt slurry. The slurry was hydrothermally reacted at 170°C for 24 hours, washed by centrifugation, dried in vacuum and heated under N at a temperature of 500°C. 2 The carbon-coated MgO sandwich structure composite nanomaterial was obtained after flow-through calcination, denoted as MgO@C-1.

Embodiment 2

[0034] Weigh 5.1g of magnesium chloride hexahydrate, 4.92g of glucose monohydrate, and 2.0g of polyvinylpyrrolidone (Mw=58000) into 150mL of 50% ethanol solution, and stir at a constant temperature of 25°C and a stirring speed of 500r / min for 20min to form a magnesium salt solution. 5mL ammonia water (analytical grade, NH 3 content of 15%-28%) was added to the magnesium salt solution at a constant speed, and stirred at a constant temperature for 120 minutes at a temperature of 25° C. and a stirring speed of 450 r / min to form a magnesium salt slurry. The slurry was hydrothermally reacted at 170°C for 24 hours, washed by centrifugation, dried in vacuum and heated under N at a temperature of 500°C. 2 The carbon-coated magnesium oxide sandwich structure composite nanomaterial was obtained after flow-through calcination, which was denoted as MgO@C-2.

Embodiment 3

[0036]Weigh 10.2g of magnesium chloride hexahydrate, 2.46g of glucose monohydrate, and 2.0g of polyvinylpyrrolidone (Mw=58000) into 150mL of 50% ethanol solution, and stir at a constant temperature of 25°C and a stirring speed of 500r / min for 30min to form a magnesium salt solution. 10mL ammonia water (analytical grade, NH 3 content of 15%-28%) was added to the magnesium salt solution at a constant speed, and stirred at a constant temperature for 150 minutes at a temperature of 25° C. and a stirring speed of 450 r / min to form a magnesium salt slurry. The slurry was hydrothermally reacted at 150°C for 18h, washed by centrifugation, dried in vacuum and heated under N at a temperature of 500°C. 2 Sandwich structure composite nanomaterials of carbon-coated MgO were obtained after flow-through calcination, denoted as MgO@C-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com