Ball cage coupler with electromagnetic brake

A technology of electromagnetic brakes and couplings, applied in the direction of couplings, elastic couplings, brake types, etc., can solve the problems of high safety hazards in mechanical equipment and special vehicles, and the difficulty and inability to install disc brakes or drum brakes and other issues, to achieve the effect of easy automatic control, compact structure, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

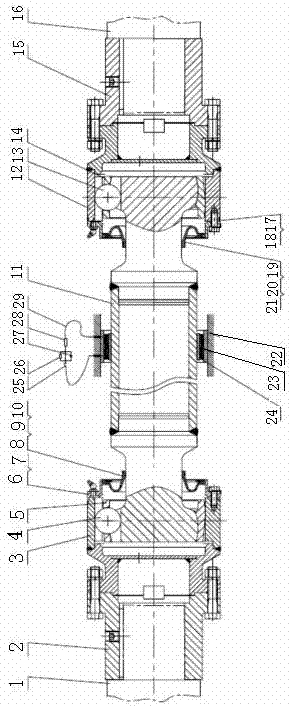

[0017] Such as figure 1 As shown, the driving shaft 16 is connected to the driving shaft flange 15 by a connecting key, the driving end outer ring 12 of the middle shaft 11 is connected to the driving shaft flange 15 by bolts and keys, the middle shaft 11, the driving end outer ring 12, and the driven shaft The end outer ring 3 has a plurality of straight grooves distributed equidistantly along the circumference, and there are steel balls 13 and steel balls 2 4 between them. The steel balls 13 and steel balls 4 are respectively installed on the cage 14 and the holder. In the window of frame two 5; the ends of the driving end outer ring 12 and the driven end outer ring 3 are equipped with a sealing system, and the gland 2 6 and the sealing gasket 2 7 of the sealing system are installed on the driven end outer ring 3. Cover one 17 and sealing gasket one 18 are installed on the outer ring 12 of the active end, sealing cover two 8 is placed in gland two 6, sealing cover one 19 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com