Negative pressure pulse oscillator

A pulse oscillator and negative pressure technology, which is applied in the field of new downhole tools and new hydraulic oscillators, can solve the problems of unsatisfactory use of axial vibration tools, inability to effectively transmit wellhead drilling pressure, and low rock-carrying capacity of drilling fluid. Achieve the effects of improving rock-carrying ability, increasing drilling speed and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

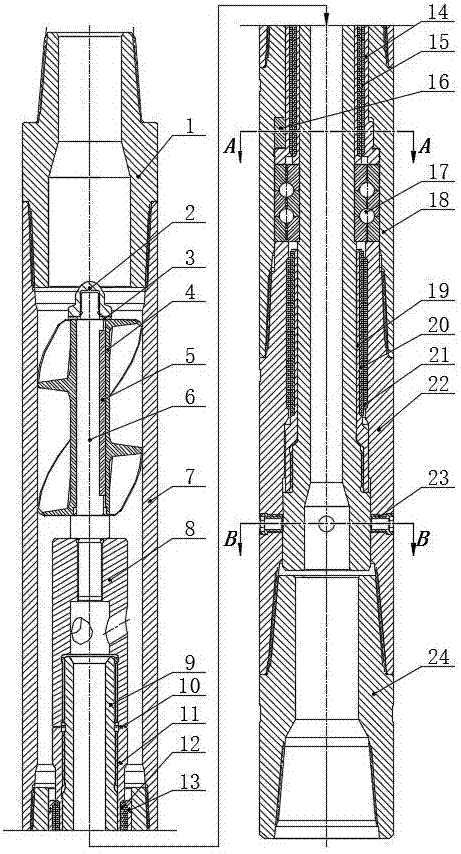

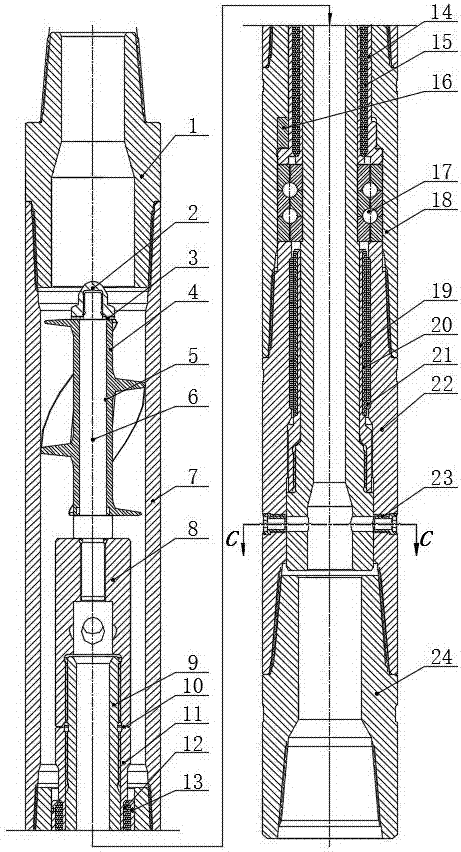

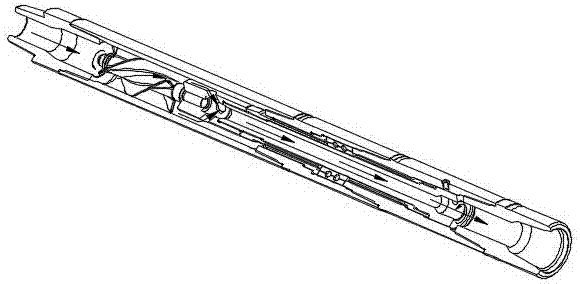

[0025] Below in conjunction with accompanying drawing, the present invention will be further described: figure 1 As shown, the negative pressure pulse oscillator is mainly composed of an upper joint, a locking cap, an adjusting gasket A, an impeller, a flat key, an impeller mandrel, an impeller shell, a water cap, a valve core tube, an adjusting gasket B, Upper TC bearing moving ring, upper TC bearing moving ring wear-resistant sleeve, type sealing ring, upper TC bearing static ring, upper TC bearing static ring wear-resistant sleeve, semicircular key, string bearing, bearing shell, lower TC bearing moving ring, The lower TC bearing moving ring wear-resistant sleeve, the lower TC bearing static ring wear-resistant sleeve, the nozzle shell, the nozzle, the lower joint, and the plug are composed of an upper joint 1, an impeller shell 7, a bearing shell 18, and a nozzle shell 22 and the lower joint 24 are sequentially threaded; the impeller 4 and the impeller mandrel 6 are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com