Refining method for recovered gutter oil

A refining method and gutter oil technology, applied in the direction of fat oil/fat refining, recovery of fat oil/fatty acid from waste materials, recycling technology, etc., can solve the problems of complicated preparation methods and low quality, achieve good decolorization, easy operation, and improved color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

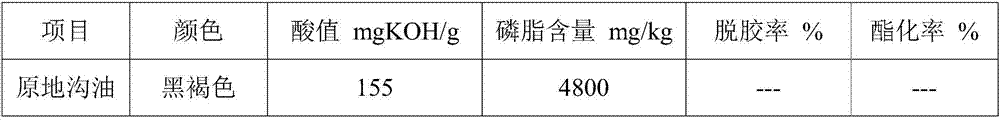

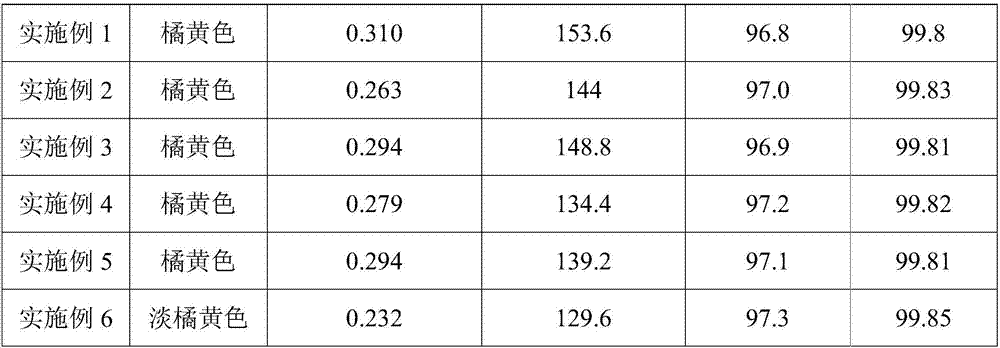

Examples

Embodiment 1

[0024] A refining method for reclaiming waste oil, comprising the steps of:

[0025] S1, take gutter oil to remove solid residue, then centrifuge and filter to obtain clear liquid oil;

[0026] S2, take S1 to obtain clear liquid oil, adjust pH, heat up, add phospholipase A2, keep warm and stir, heat up, centrifuge to take the upper oil phase to obtain degummed oil;

[0027] S3, adding a chemical decolorizer to the degummed oil obtained in S2, heating up, insulated and stirred, then adding diatomaceous earth and activated carbon, heating up, insulated and stirred, and filtering to get the filtrate;

[0028] S4. Add glycerin to the filtrate obtained in S3, heat up, keep warm and stir to obtain refined waste oil.

Embodiment 2

[0030] A refining method for reclaiming waste oil, comprising the steps of:

[0031] S1. Take gutter oil to remove solid residues, and then centrifuge and filter to obtain clear liquid oil. The centrifugation speed is 10000r / min, the centrifugation time is 10min, the filtration temperature is 80°C, and the nano-overfrequency vibration module is used for filtration;

[0032] S2. Take the supernatant oil obtained from S1, adjust the pH=6, heat up to 50°C, add phospholipase A2, heat and stir for 4 hours, heat up to 80°C, and centrifuge to take the upper oil phase to obtain degummed oil;

[0033] S3. Add a chemical decolorizer to the degummed oil obtained in S2, heat up to 70° C., heat and stir for 20 minutes, then add diatomaceous earth and activated carbon, heat up to 85° C., heat and stir for 15 minutes, and filter to get the filtrate;

[0034] S4. Add glycerin to the filtrate obtained in S3, raise the temperature to 230° C., keep stirring for 2.5 hours, and cool to room temper...

Embodiment 3

[0036] A refining method for reclaiming waste oil, comprising the steps of:

[0037] S1. Take gutter oil to remove solid residue, and then centrifuge and filter to obtain clear liquid oil. The centrifugation speed is 15000r / min, the centrifugation time is 8min, the filtration temperature is 90°C, and the nano-overfrequency vibration module is used for filtration;

[0038] S2. Take the supernatant oil obtained from S1, adjust the pH=5.5 with citric acid, heat up to 60°C, add phospholipase A2, keep stirring for 3 hours, heat up to 90°C, and centrifuge to take the upper oil phase to obtain degummed oil, wherein the supernatant The weight ratio of oil and phospholipase A2 is 100:1;

[0039] S3. Add a chemical decolorizer to the degummed oil obtained in S2, heat up to 60° C., heat and stir for 30 minutes, then add diatomaceous earth and activated carbon, heat up to 75° C., heat and stir for 25 minutes, and filter to get the filtrate, wherein, the degummed oil, The weight ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com