A preparation method of fluorocarbon-modified heat-conducting heavy-duty anti-corrosion coating suitable for heating crude oil containing water

A fluorocarbon modification, heavy-duty anti-corrosion technology, applied in the field of metal anti-corrosion, can solve the problems of poor metal surface adhesion, inability to soak, poor anti-corrosion performance, etc., achieve good oil and water resistance, improve oil and water resistance, and excellent thermal conductivity. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

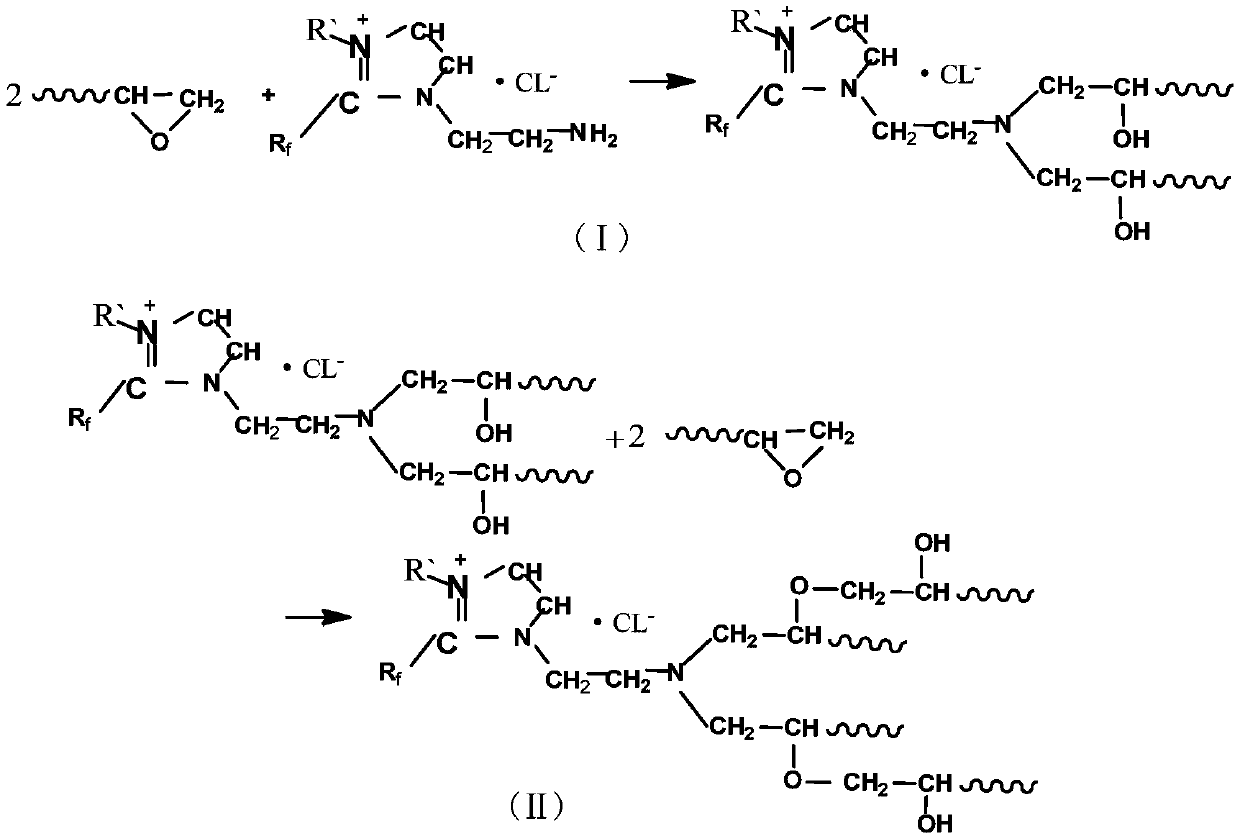

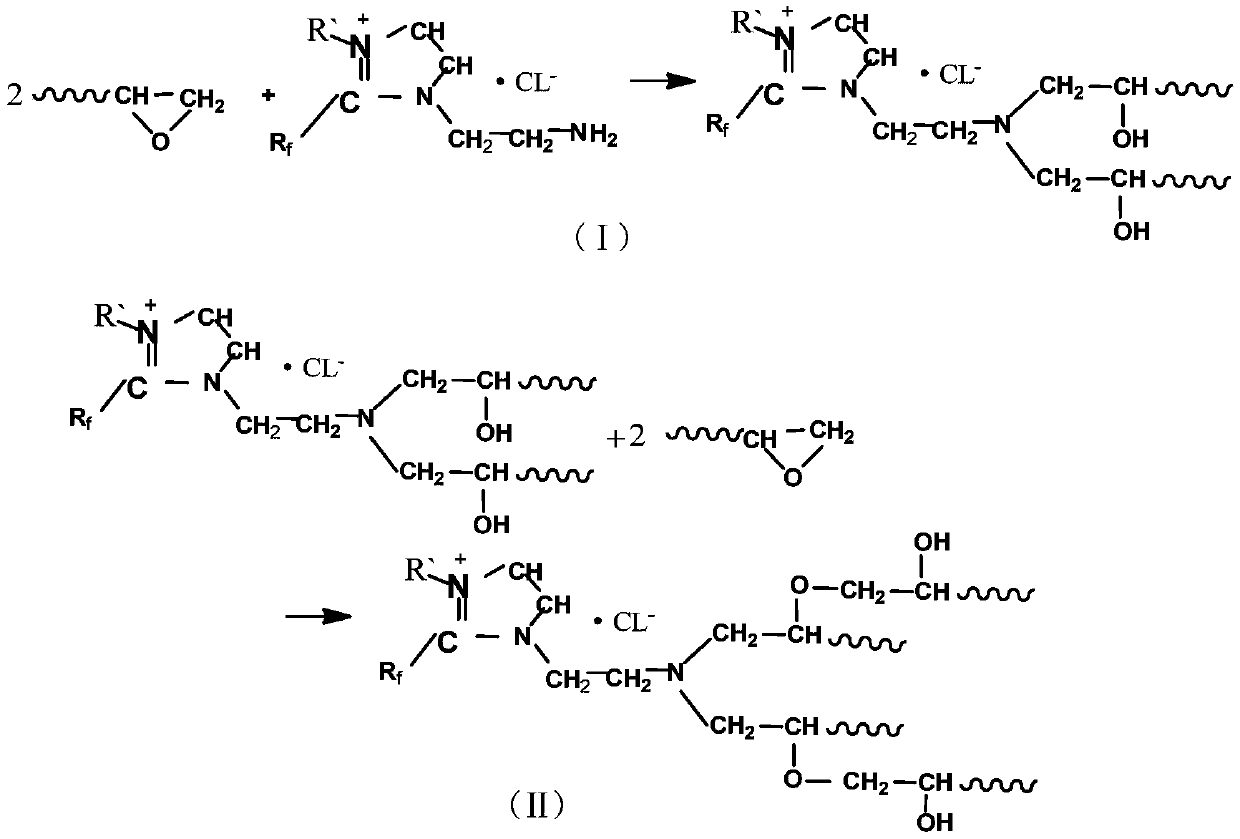

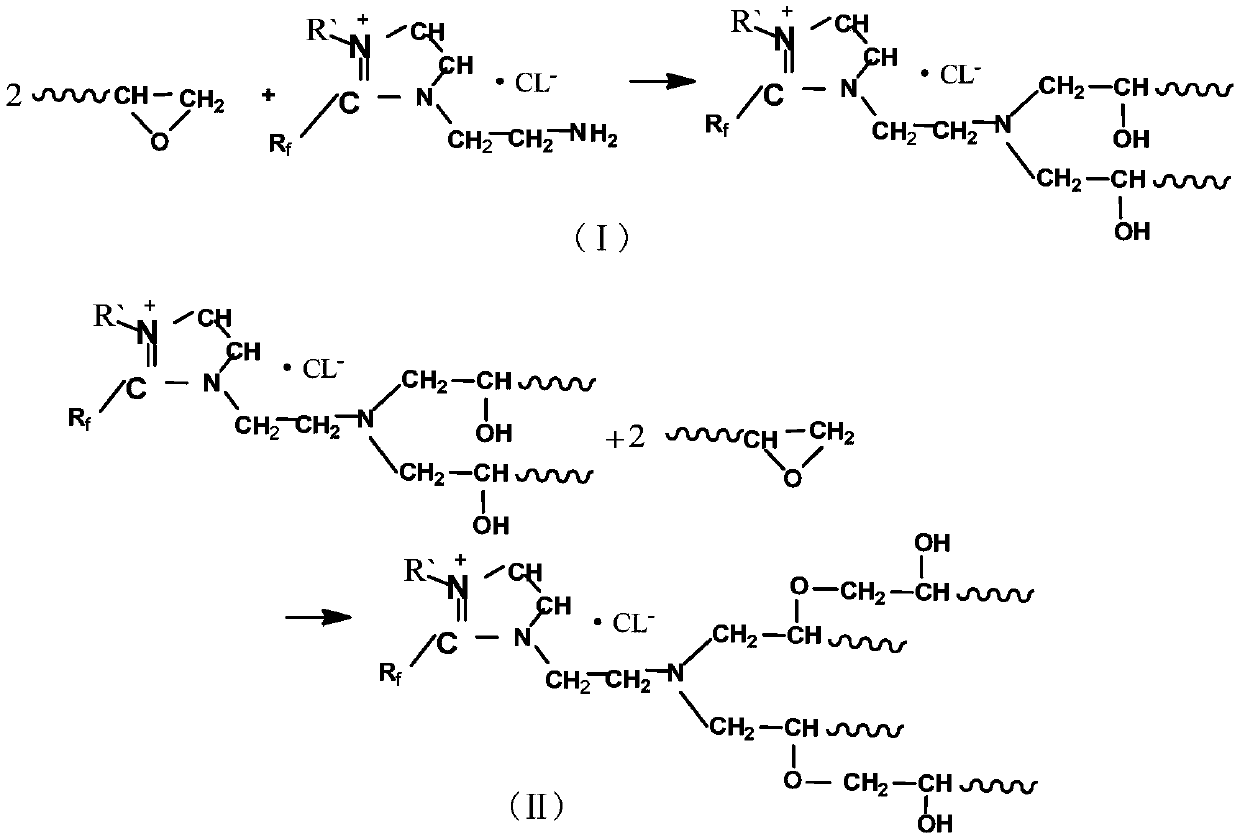

Method used

Image

Examples

Embodiment 1

[0016] Epoxy resin E44, n-butanol, xylene (mixture of three isomers), graphite powder, hexagonal boron nitride, 6006 leveling agent in the ratio of 58:35:85:20:20:1 (mass Than) mixing with a three-roll machine and grinding until the slurry fineness is below 20 μm (measured by a scraper fineness meter), and then filtering with a 120-mesh filter cloth to obtain component A. Mix and stir 651 polyamide resin, n-butanol, xylene (a mixture of three isomers), and fluorocarbon imidazoline quaternary ammonium salt in a ratio (mass ratio) of 20.4:13.6:33:10 to obtain B components. Mix component A and component B at a ratio (mass ratio) of 3:1, stir evenly, and cure at room temperature for 15 to 20 minutes to obtain the fluorocarbon modified thermally conductive heavy-duty anti-corrosion coating. Spray the paint on the surface of the tinplate test plate and 20# steel pipe for 3 times, and measure the adhesion of the paint film with the QFZ paint film adhesion tester (Tianjin Jingke Mate...

Embodiment 2

[0020] Epoxy resin E44, n-butanol, xylene (mixture of three isomers), graphite powder, hexagonal boron nitride, 6006 leveling agent in the ratio of 58:36:86:21:21:1.1 (mass Than) mixing with a three-roll machine and grinding until the slurry fineness is below 20 μm (measured by a scraper fineness meter), and then filtering with a 120-mesh filter cloth to obtain component A. Mix and stir 651 polyamide resin, n-butanol, xylene (a mixture of three isomers), and fluorocarbon imidazoline quaternary ammonium salt in a ratio (mass ratio) of 22.6:14.5:34.6:15 to obtain B components. Mix component A and component B at a ratio (mass ratio) of 3:1, stir evenly, and cure at room temperature for 15 to 20 minutes to obtain the fluorocarbon modified thermally conductive heavy-duty anti-corrosion coating. Spray the paint on the surface of the tinplate test plate and 20# steel pipe for 3 times, and measure the adhesion of the paint film with the QFZ paint film adhesion tester (Tianjin Jingke ...

Embodiment 3

[0022] With epoxy resin E44, n-butanol, xylene (mixture of three isomers), graphite powder, hexagonal boron nitride, 6006 leveling agent in the ratio of 58:37:87:22:22:1.2 (mass Than) mixing with a three-roll machine and grinding until the slurry fineness is below 20 μm (measured by a scraper fineness meter), and then filtering with a 120-mesh filter cloth to obtain component A. Mix and stir 651 polyamide resin, n-butanol, xylene (a mixture of three isomers), and fluorocarbon imidazoline quaternary ammonium salt in a ratio (mass ratio) of 23.4:15.2:36:20 to obtain B components. Mix component A and component B at a ratio (mass ratio) of 3:1, stir evenly, and cure at room temperature for 15 to 20 minutes to obtain the fluorocarbon modified thermally conductive heavy-duty anti-corrosion coating. Spray this paint on the surface of the tinplate test plate 3 times. After the paint film is dry, use the QFZ paint film adhesion tester (Tianjin Jingke Material Testing Machine Factory)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com