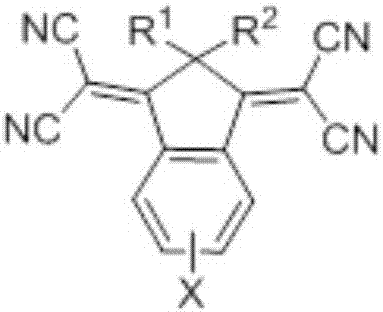

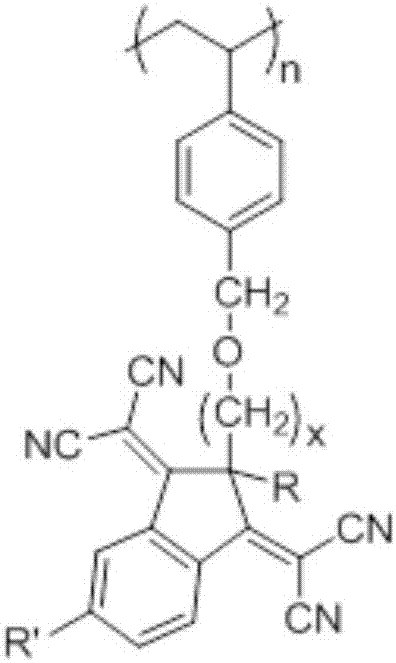

Polymer electron transport materials containing DCMI functional groups and application thereof

A technology of electron transport materials and polymers, applied in the field of organic photoconductive drums, to achieve the effects of simple operation, reduced possibility, and poor processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

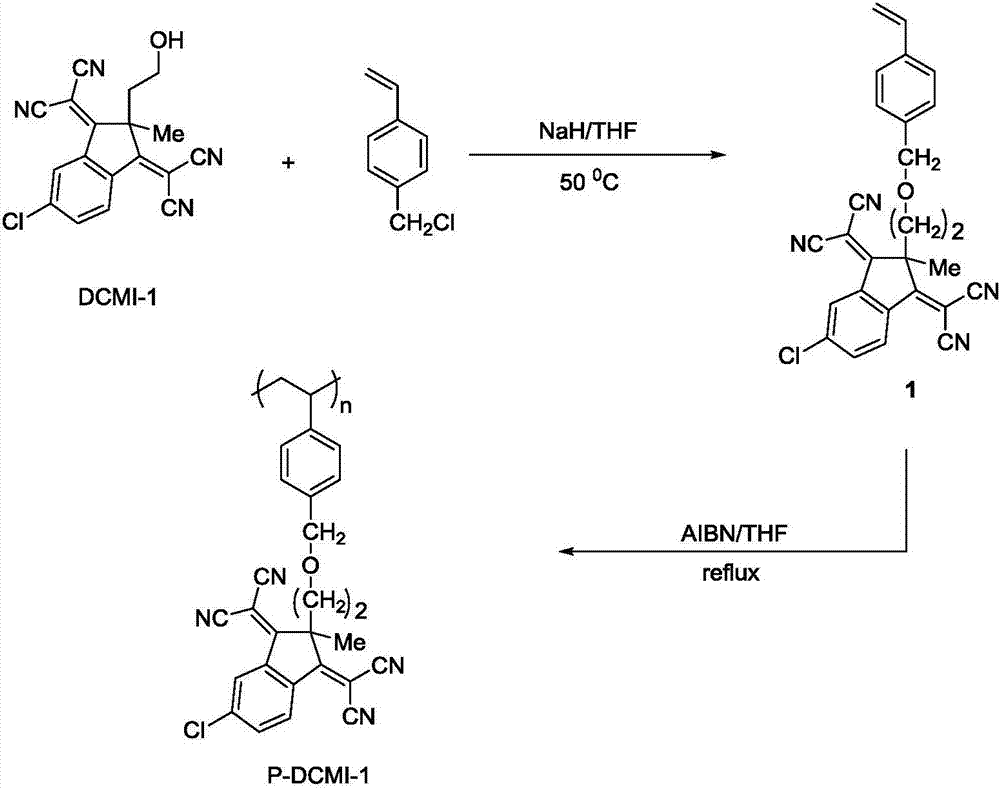

Method used

Image

Examples

Embodiment 1

[0028] In a 500ml ball mill jar, add 3g of Y-TiOPc, 2g of PVB, 250ml of cyclohexanone and 200ml of strengthened glass beads (Ф2mm~3mm), and disperse on a ball mill at a speed of 180 rpm for 6 hours , to obtain the coating solution I; the coating solution I was coated on an anodized aluminum tube (diameter 24mm, length 240mm) by dip coating, and dried at 80°C for half an hour to obtain a charge generation layer with a thickness of about 0.5 microns; 10 One gram of P-DCMI-1 and 20 grams of PCZ-300 were dissolved in 300 ml of tetrahydrofuran, and mixed uniformly to obtain coating solution II; the coating solution II was coated on the charge generation layer by dip coating, and dried at 100°C for 1 Hours, form a charge transport layer with a thickness of about 20 microns on the charge generation layer to obtain a positively charged organic photoconductive drum

Embodiment 2

[0029] Embodiment 2: Except that the amount of P-DCMI-1 is increased from 10 grams to 15 grams, everything else is the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com