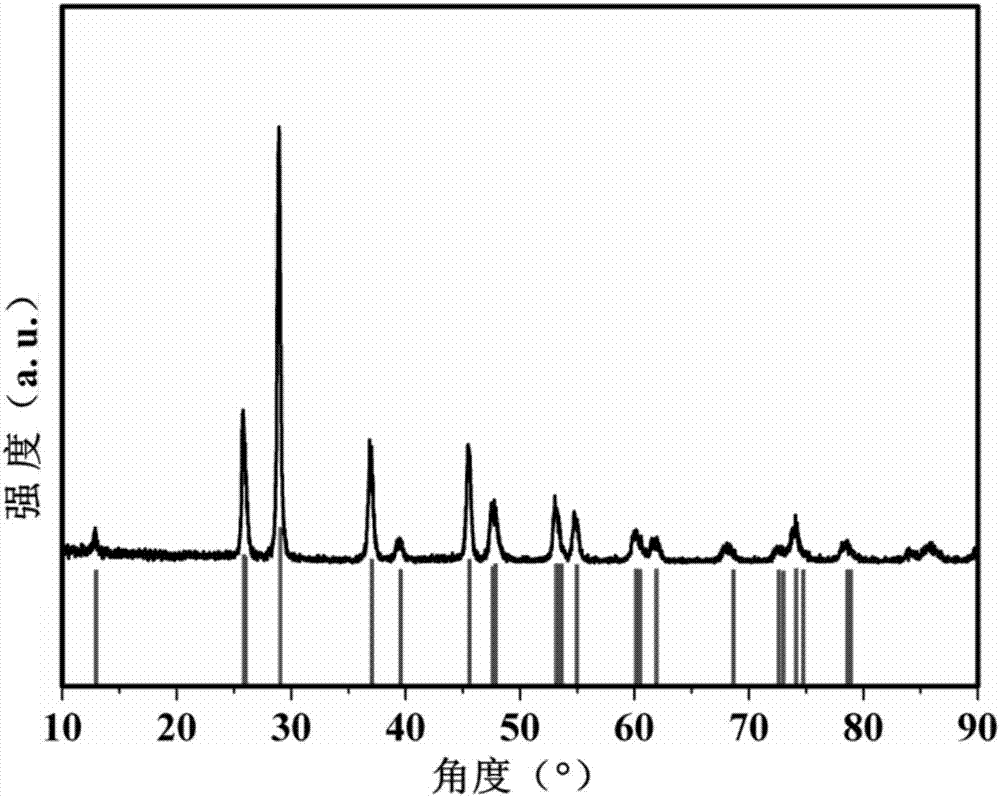

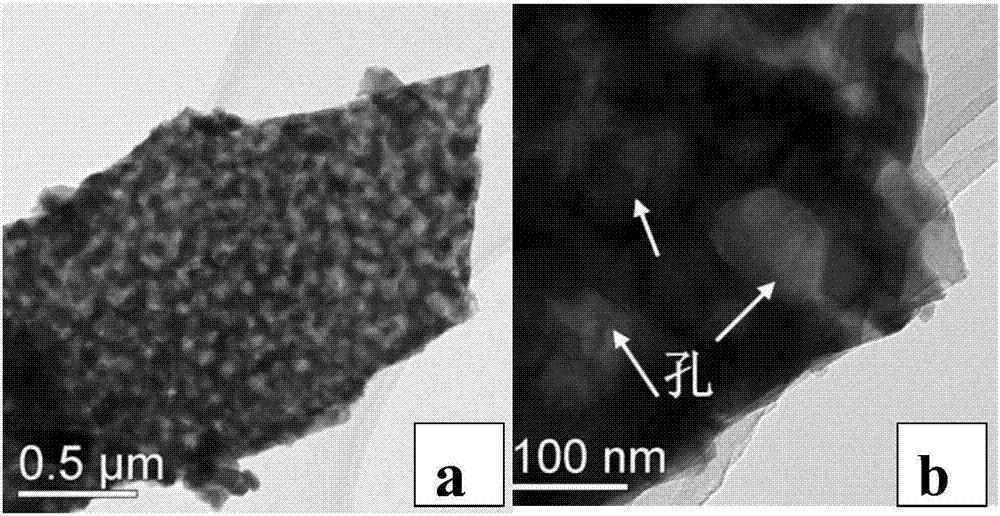

Preparation method of cerium oxysulfide porous nano-sheets

A technology of cerium sulfide and nanosheets, which is applied in chemical instruments and methods, nanotechnology, rare earth metal sulfides, etc., can solve problems such as the difficulty in preparing pure-phase cerium oxysulfide nanomaterials, and achieve improved specific surface area, reaction conditions and devices simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of porous cerium oxysulfide nanosheets, the operation steps are as follows:

[0026] (1) Take by weighing 2.5mmol of cerium acetate, join in 20ml of deionized water, stir to fully dissolve cerium acetate in deionized water, obtain a cerium acetate solution containing cerium ion molar concentration of 0.125mol / L, weigh 1.25mmol Add thiourea to the obtained cerium acetate solution and mix, stir evenly, then add 15ml of ethylene glycol amine to the mixture of thiourea and cerium acetate solution, stir evenly, then transfer to a polytetrafluoroethylene hydrothermal kettle for sealing, Heating, when the temperature rises to 250°C, keep it warm for 24 hours to carry out hydrothermal reaction, and cool to room temperature;

[0027] (2) Suction filter the material obtained after cooling in step (1), take the filter residue, wash away the unreacted ethylene glycol amine with deionized water, dry the obtained filter residue after cleaning until the moisture i...

Embodiment 2

[0029] A preparation method of porous cerium oxysulfide nanosheets, the operation steps are as follows:

[0030] (1) take by weighing the cerium nitrate of 2.08mmol, join in the deionized water of 20ml, stir and make cerium nitrate fully dissolve in deionized water, obtain the cerium nitrate solution that the molar concentration of cerium ion is 0.104mol / L, weigh 1.25mmol Add ethylene thiourea to the obtained cerium nitrate solution and mix, stir evenly, then add 15ml of ethylene glycol amine into the mixture of ethylene thiourea and cerium nitrate solution, stir evenly, then transfer to a polytetrafluoroethylene hydrothermal kettle Seal, heat, keep warm for 30 hours when the temperature rises to 180°C for hydrothermal reaction, and cool to room temperature;

[0031] (2) Suction filter the material obtained after cooling in step (1), take the filter residue, wash away the unreacted ethylene glycol amine with deionized water, dry the obtained filter residue after cleaning until...

Embodiment 3

[0033] A preparation method of porous cerium oxysulfide nanosheets, the operation steps are as follows:

[0034] (1) take by weighing the cerium chloride of 3.0mmol, join in the deionized water of 20ml, stir and make cerium chloride fully dissolve in deionized water, obtain the cerium chloride solution that contains cerium ion molar concentration and be 0.15mol / L, weigh Take 2.4mmol of thiouracil and add it to the obtained cerium chloride solution and mix, stir evenly, then add 15ml of ethylene glycol amine into the mixture of thiouracil and cerium chloride solution, stir evenly, and then transfer to the polytetrafluoroethylene Seal it in an ethylene hydrothermal kettle, heat it, keep it warm for 24 hours when the temperature rises to 185°C, and carry out hydrothermal reaction, and cool to room temperature;

[0035] (2) Suction filter the material obtained after cooling in step (1), take the filter residue, wash away the unreacted ethylene glycol amine with deionized water, dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com