Arc-protective garment

A technology of anti-arc and comfortable layer, which is applied in the direction of clothing, clothing, clothing, etc., can solve the problems of burns and easy burns of the protected personnel, and achieve the effects of improving thermal protection performance, low cost, and improving heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

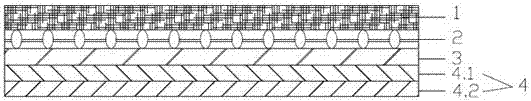

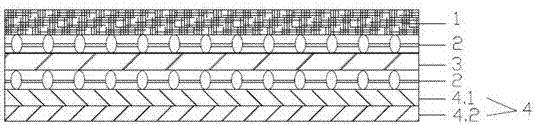

[0033] like figure 1 As shown, the arc-proof clothing includes an arc-proof surface layer 1, and is characterized in that it also includes two layers of comfort layers 3, 4 positioned inside the arc-proof surface layer 1, between the arc-proof surface layer 1 and the comfort layer 3, There is also a support layer 2 with protrusions on both sides of one layer of fabric. like figure 2 As shown, the arc-proof chest, back and limbs include one more support layer 2 than other positions, and the extra layer is arranged between the comfort layers 3 and 4 .

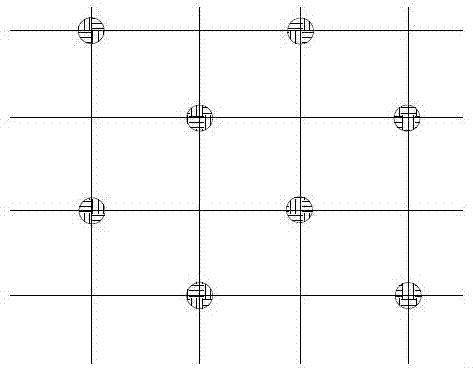

[0034] The support layer is a mesh structure, and the intersection part of the mesh is knot-shaped, and it is sewn between the anti-arc surface layer and the comfort layer through flame-retardant threads, such as image 3 and 4 Shown are two different support layer structures.

[0035] like Figure 5 As shown, 1, 2, 3, and 4 in the figure indicate the warp and weft yarns of the outer layer, and I, II, III, and IV indicate t...

Embodiment 2

[0043] The arc protection clothing described in the above-mentioned embodiment 1 is all the same except that the structure of the comfort layer 4 is different. In the present embodiment, the comfort layer 4 includes a front layer 4.1 and a back layer 4.2, the front layer and the back layer both include fabric one and fabric two, the back side of fabric one is fabric two, the back side of fabric two is fabric one, and the back side of fabric two is fabric one. The high-temperature carbonization shrinkage of fibers in fabric 1 and fabric 2 is different. When encountering an arc explosion, the side with a small heat shrinkage will bulge. Since there are two different yarns on the front and back, each side will have a bulge, such as Figure 7 As shown, this will create a larger thermal insulation space than the traditional fabric with only one side raised, so as to achieve a better thermal insulation protection effect.

Embodiment 3

[0045] The arc-proof clothing described in the above-mentioned embodiment 1 is the same except that the support layer is set into the arc-proof surface layer and the connection mode of the comfort layer is different. The present embodiment adopts the non-continuous, Non-tight connection, the total thickness of the air layer formed between the layers is 6-14mm. Under the condition that the ambient temperature is 25°C, the skin temperature is 33°C, and the wind speed is 0.1m / s, the experiment shows that if Figure 8 As shown, the influence of the thickness of the air layer under the clothes on the total sensible heat and the heat flux of each component: when the thickness of the air layer is less than 16 mm, the sensible heat transfer through the air layer under the clothes is heat conduction and radiation. As the temperature increases, the conduction heat gradually decreases, while the radiant heat gradually increases. This is because radiant heat has nothing to do with the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com