Fiber reinforced composite material fusing and steeping device capable of achieving tension online adjustment and preparation method

A melt impregnation and composite material technology, which is applied in the field of continuous fiber reinforced composite material processing, can solve the problems of high fracture rate of composite materials, difficult processing and production, fixed fiber bundle impregnation channel form, etc., and achieves simple production operation and excellent impregnation effect , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

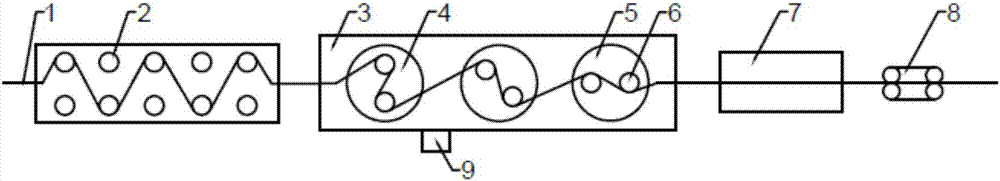

[0048] On the other hand, the present invention also provides a method for preparing a continuous fiber-reinforced thermoplastic resin by melt impregnation, comprising the following steps:

[0049] (1) Carry out detwisting and preheating treatment to the continuous fiber bundle 1;

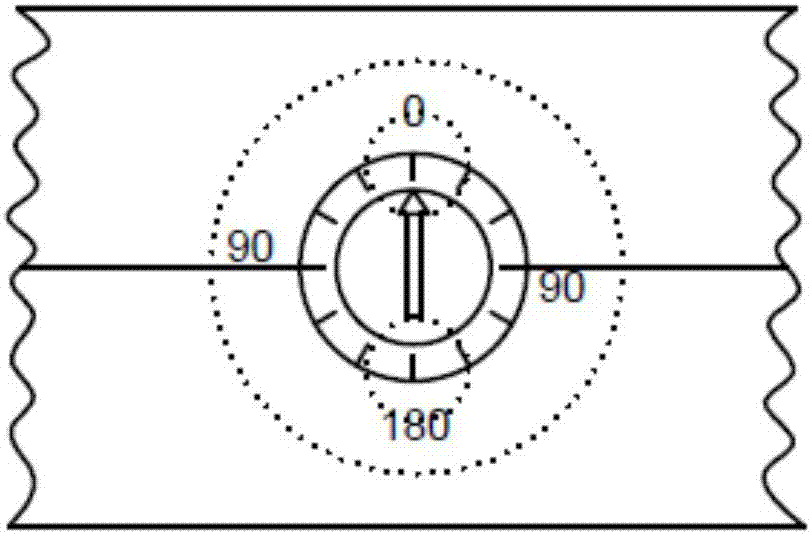

[0050] (2) Draw the continuous fiber bundle 1 into the melt impregnation mold 3, adjust the wrapping angle and the tension of the continuous fiber bundle 1 through a plurality of rotatable impregnation devices arranged in the melt impregnation mold 3, so that the continuous fiber bundle can be obtained Disperse; at the same time, extrude the plasticized thermoplastic resin melt into the melt impregnation mold 3, so that the continuous fiber bundle 1 is impregnated to form a prepreg composite material;

[0051] (3) Cool and set the prepreg composite material.

[0052] Preferably, the continuous fiber bundle 1 in step (1) includes but not limited to glass fiber, carbon fiber, basalt fiber or aramid fi...

Embodiment 1

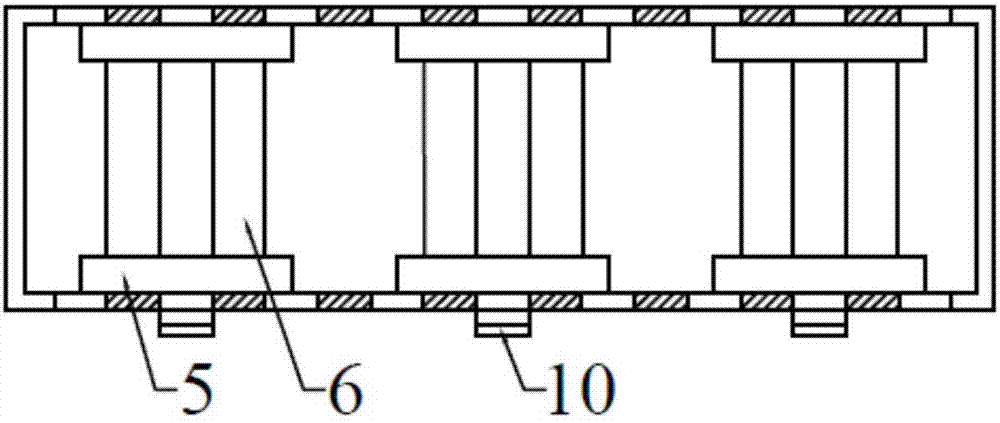

[0061] A method for preparing continuous fiber-reinforced thermoplastic resin by melt impregnation. The continuous fiber bundle is selected from carbon fiber, and the thermoplastic resin is selected from nylon 66; the temperature of the melt impregnation mold is set to 280°C, and three rotating impregnation devices are installed and arranged at a distance of 80mm; the diameter of the impregnation roller The diameter of the rotating disk is 60mm; the temperature of the feeding section, compression section and metering section of the extruder is 260°C, 275°C, and 285°C respectively.

[0062] This embodiment selects a group of comparative experiments, scheme 1 is that all three rotating dipping devices are rotated 90°, scheme 2 is that all three rotating dipping devices are turning 120°, scheme 3 is that all three rotating dipping devices are turning 150°, the test results See Table 1.

Embodiment 2

[0064] A method for preparing continuous fiber-reinforced thermoplastic resin by melt impregnation. The continuous fiber bundle 1 is selected from glass fiber, and the thermoplastic resin is selected from polypropylene; the temperature of the melt impregnation mold is set at 230°C, and 4 rotating impregnation devices are installed and arranged at a distance of 50 mm; impregnation rollers The diameter of the rotary disc is 10mm, and the diameter of the rotating disc is 40mm; the temperatures of the feeding section, compression section, and metering section of the extruder are 150°C, 220°C, and 230°C, respectively.

[0065] This embodiment selects a group of comparative experiments. In scheme 1, all 4 rotating impregnating devices rotate 135°, and in scheme 2, the angles of rotation of 4 rotating impregnating apparatuses are 180°, 150°, 120° and 90° respectively. For the test results, see Table 2.

[0066] It can be seen from Table 1 that through comparative experiments on diffe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com