Cutting method of laser cutting machine

A technology of laser cutting machine and cutting method, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of poor flatness of carbon steel cutting surface, affect the quality of carbon steel, and poor stability, so as to improve the flatness , Improve stability, increase the effect of friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

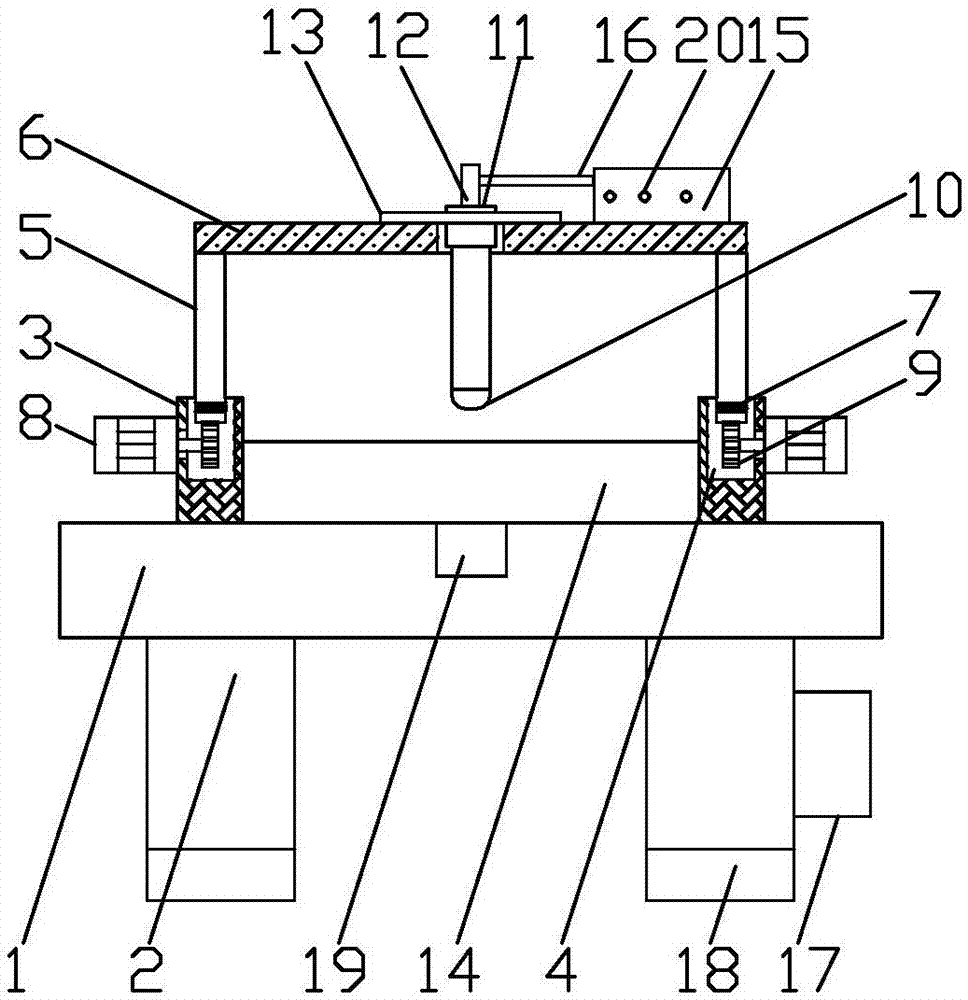

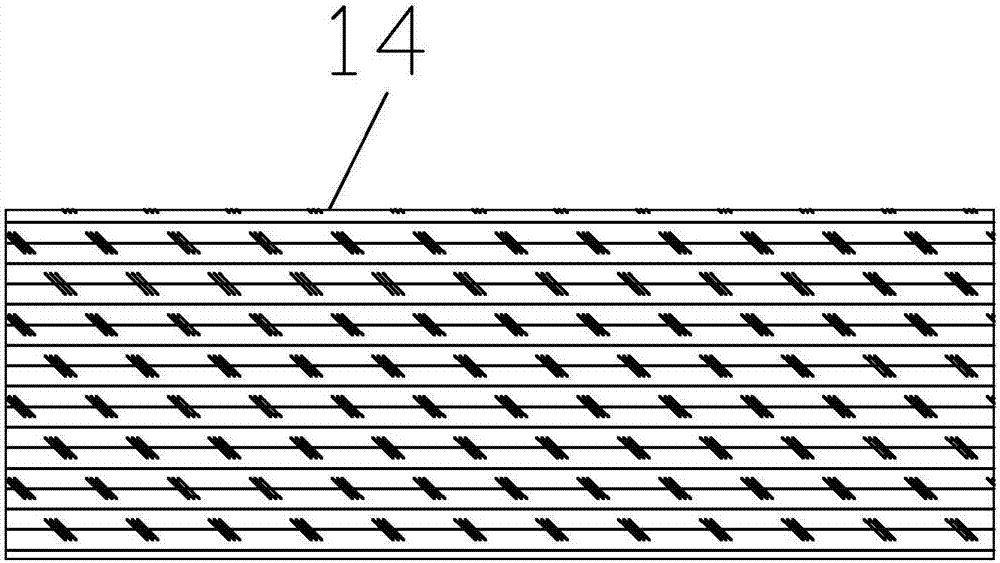

[0019] First get a carbon steel plate body 14 with a thickness of 20 millimeters and fix it on the surface of the support panel 1, start the control box 15 by the controller 17, and the equipment is set to continuous power by the control box 15 and the power is 2,000 watts, cutting height 0.7 millimeters, the focal point is 3, the nozzle is 4.0, and the speed is 600 meters per minute, then the laser cutting pen 10 is started by the control box 15, and the laser beam irradiated by the laser cutting pen 10 is applied to the support panel 1 surface. The carbon steel plate body 14 is cut, and then the motor 8 drives the gear 9 and the tooth plate 7 to move, the tooth plate 7 drives the movable plate 5 and the top plate 6 to move, the top plate 6 drives the laser cutting pen 10 to move forward and backward at a uniform speed, and the laser cutting pen 10 When the laser cuts on the surface of the carbon steel plate body 14, the carbon steel plate body 14 can be cut open. After the cu...

Embodiment 2

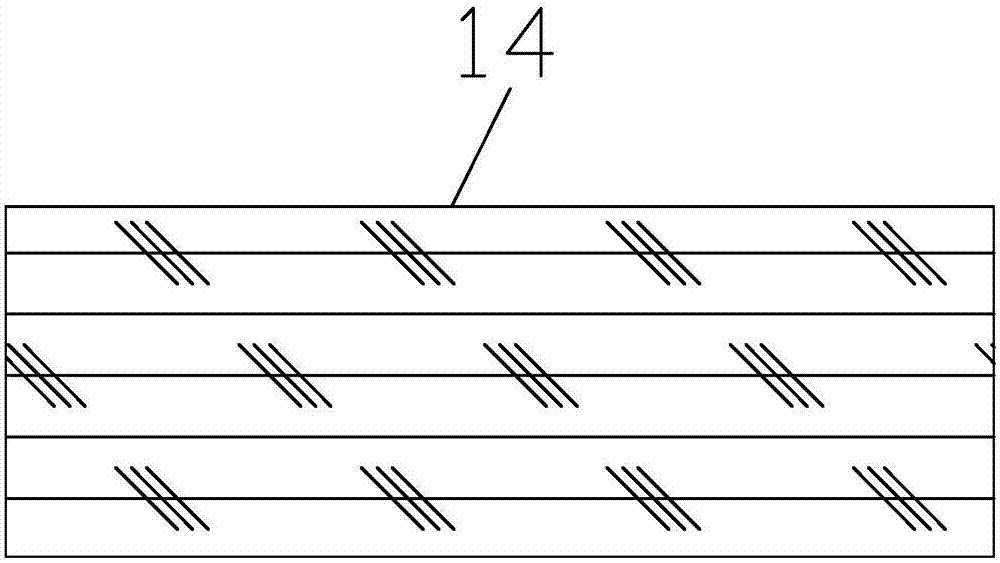

[0021] First get a carbon steel plate body 14 with a thickness of 20 millimeters and fix it on the surface of the support panel 1, start the control box 15 by the controller 17, and set the equipment to the frequency processing mode by the control box 15 and the power is 3,000 watts, the frequency 1000, the duty cycle is 65%, the cutting height is 0.7 mm, the focus is 2.5, the nozzle is 4.0, the speed is 600 meters per minute, and then the laser is started through the control box 15 The cutting pen 10 cuts the carbon steel plate body 14 on the surface of the support panel 1 through the laser light irradiated by the laser cutting pen 10, and then drives the gear 9 and the tooth plate 7 to move through the motor 8, and drives the movable plate 5 and the top plate 6 through the tooth plate 7 Movement, through the top plate 6 to drive the laser cutting pen 10 to move forward and backward at a uniform speed, through the uniform motion of the laser cutting pen 10, the laser cuts on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com