Method for separating particulate matter, sulfur vapor and sulfur dioxide in smoke and application of method

A sulfur dioxide and sulfur vapor technology, applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve problems such as poor economy, complex process, ineffective separation, etc., and achieve reduced energy consumption, simple process, and low filtration pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

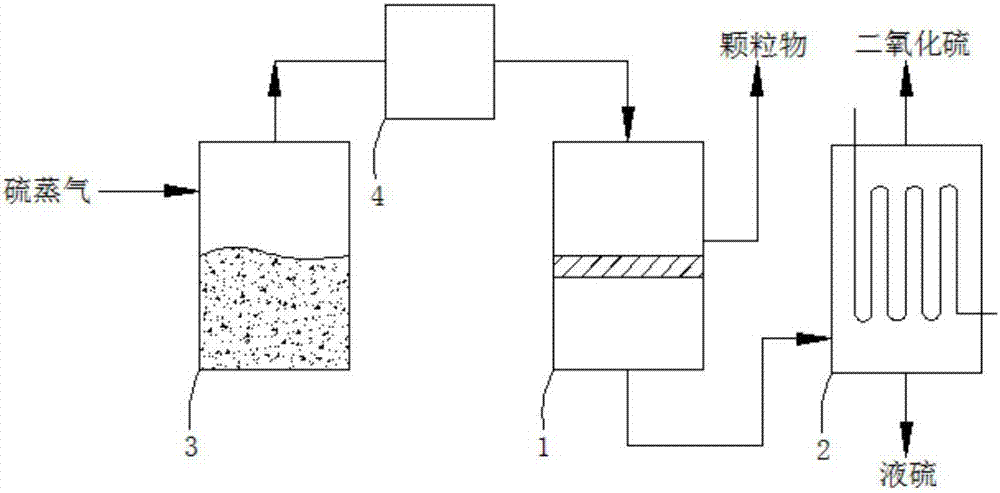

[0045] Such as figure 2 Shown, the method for particulate matter, sulfur vapor and sulfur dioxide in the separation flue gas of the present invention comprises the following steps:

[0046] 1) Using the heat recovery device 4 to reduce the temperature of the flue gas to 350° C., wherein the flue gas is a gas composed of particulate matter, sulfur vapor and sulfur dioxide produced by the reaction of sulfur vapor and phosphogypsum;

[0047] 2) Use the membrane filter 1 to filter the cooled flue gas, the filtering temperature is 300°C, and the filtering wind speed is 0.5m / min; the particulate matter in the flue gas is intercepted by the filter medium of the membrane filter 1, The flue gas passes through the filter medium of the membrane filter 1 to obtain the first flue gas; the material of the filter medium is an intermetallic compound, the pore size is 10 μm, and the gas flux is 300 m 3 / m 2 kPa h;

[0048] 3) The first flue gas passes through a condenser 2 with a condensat...

Embodiment 2

[0051] Such as figure 2 Shown, the method for particulate matter, sulfur vapor and sulfur dioxide in the separation flue gas of the present invention comprises the following steps:

[0052] 1) Using the heat recovery device 4 to reduce the temperature of the flue gas to 400° C., wherein the flue gas is a gas composed of particulate matter, sulfur vapor and sulfur dioxide produced by the reaction of excess sulfur vapor and phosphogypsum;

[0053] 2) Use the membrane filter 1 to filter the cooled flue gas, the filtration temperature is 350°C, and the filtration wind speed is 0.9m / min; the particulate matter in the flue gas is intercepted by the filter medium of the membrane filter 1, The flue gas passes through the filter medium of the membrane filter 1 to obtain the first flue gas; the material of the filter medium is an intermetallic compound, the pore size is 15 μm, and the gas flux is 480 m 3 / m 2 kPa h;

[0054] 3) The first flue gas is passed through a condenser 2 with...

Embodiment 3

[0057] Such as figure 2 Shown, the method for particulate matter, sulfur vapor and sulfur dioxide in the separation flue gas of the present invention comprises the following steps:

[0058] 1) Using the heat recovery device 4 to reduce the temperature of the flue gas to 450° C., wherein the flue gas is a gas composed of particulate matter, sulfur vapor and sulfur dioxide produced by the reaction of excess sulfur vapor and phosphogypsum;

[0059] 2) Use the membrane filter 1 to filter the cooled flue gas, the filtration temperature is 400°C, and the filtration wind speed is 1.3m / min; the particulate matter in the flue gas is intercepted by the filter medium of the membrane filter 1, The flue gas passes through the filter medium of the membrane filter 1 to obtain the first flue gas; the material of the filter medium is an intermetallic compound, the pore size is 20 μm, and the gas flux is 570 m 3 / m 2 kPa h;

[0060] 3) Make the first flue gas pass through a condenser 2 with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com