Dispersing agent special for pesticide water suspension agent and preparation method thereof

A technology of dispersing agent and suspending agent, applied in the agricultural field, can solve the problems of difficult control of molecular weight and distribution, unsatisfactory hard water resistance, etc., and achieve the effects of excellent dispersion performance, no environmental pollution, and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

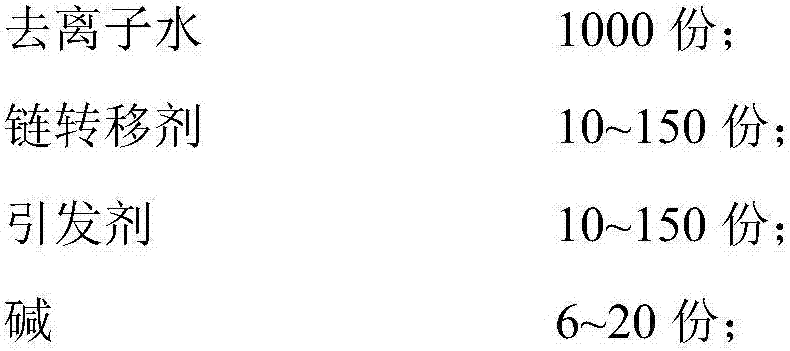

[0027] 1) The special dispersant for pesticide aqueous suspension concentrate of the present embodiment is prepared according to the following steps:

[0028] Add 1000 parts of deionized water and 10 parts of sodium formate into a four-necked reaction flask, and heat while stirring; 500 parts of maleic acid and 10 parts of potassium persulfate were added within 1 hour, and then kept at 60°C for 2 hours (to obtain solution 2); after the heat preservation reaction was completed, the temperature was lowered to room temperature while stirring, and the system was neutralized with sodium hydroxide solution (i.e. in the solution 2) of the carboxylic acid, the neutralization amount is 50% of the molar number of the carboxylic acid to obtain the target dispersant solution; the dispersant solution is prepared according to the existing spray drying method to obtain the pesticide water of the present embodiment Special dispersant powder for suspending agent.

[0029] Adopt Gel Permeation...

Embodiment 2

[0036] The special dispersant for pesticide aqueous suspension concentrate of the present embodiment is prepared according to the following steps:

[0037] Add 1000 parts of deionized water and 100 parts of sodium formate into a four-necked reaction flask, and heat while stirring; when the temperature of the solution in the reaction flask rises to 70°C, add 200 parts of 2-vinylpyridine, 500 parts of maleic anhydride And 60 parts of potassium persulfate, add in 3 hours, then heat preservation reaction 2 hours; After heat preservation reaction finishes, drop to room temperature while stirring, neutralize the carboxylic acid in the system with sodium hydroxide solution, the neutralization amount is the carboxylic acid mole number 90% of the target dispersant solution was obtained; this dispersant solution was spray-dried to obtain the special dispersant powder for pesticide aqueous suspensions of the present embodiment.

[0038] Using gel permeation chromatography, using water as...

Embodiment 3

[0040] The special dispersant for pesticide aqueous suspension concentrate of the present embodiment is prepared according to the following steps:

[0041] Add 1000 parts of deionized water and 20 parts of sodium formate into a four-necked reaction flask, and heat while stirring; when the temperature of the solution in the reaction flask rises to 80°C, add 200 parts of 2-vinylpyridine, 600 parts of acrylic acid and Parts of potassium persulfate, added within 2 hours, then heat-preserved for 3 hours; after the heat-preserved reaction was completed, it was lowered to room temperature while stirring, and the carboxylic acid in the system was neutralized with sodium hydroxide solution, and the neutralization amount was 80% of the molar number of carboxyl groups , to obtain the target dispersant solution; the dispersant solution is spray-dried to obtain the special dispersant powder for pesticide aqueous suspension in this embodiment.

[0042] Using gel permeation chromatography, u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com