Preparation method of dual-oxide/graphene nanometer composite electrode material

A nanocomposite, double oxide technology, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nanotechnology, etc., to achieve the effect of reducing current impedance, strong cycle stability, and increasing specific capacitance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the preparation of a kind of double oxide / graphene nanocomposite electrode material:

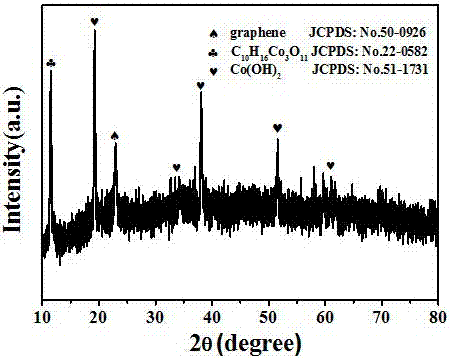

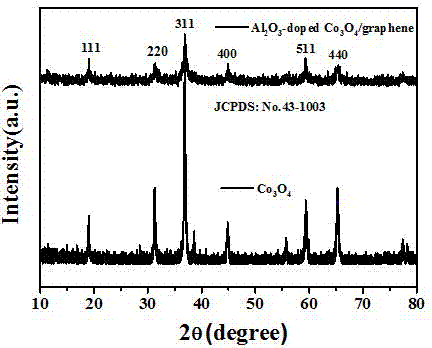

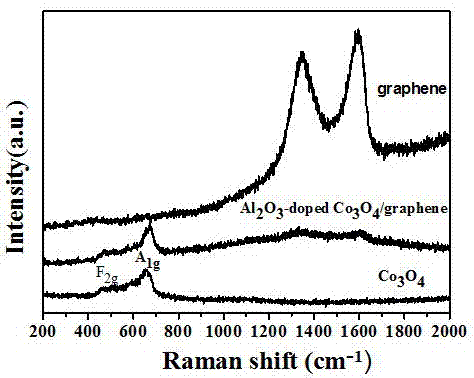

[0030] First, weigh 1.19 grams of cobalt chloride hexahydrate and 0.075 grams of aluminum nitrate nonahydrate and dissolve them in a small beaker containing 30 ml of distilled water, continue to add 4 ml of graphene (2.6 mg / ml), and after ultrasonic for 30 minutes, stir under magnetic force While stirring, continue to add 2 ml of ammonia water drop by drop, take out the magnet, transfer the mixed solution to a stainless steel autoclave with a volume of 50 ml containing a polytetrafluoroethylene liner, seal the autoclave, and place it at 180 Take it out after 12 hours in an oven at 100°C, cool it naturally to room temperature, and centrifuge at 8,000 rpm for 5 minutes to obtain a precipitate, wash with distilled water and ethanol three times, put the precipitate in a 60-degree oven, and place it for 12 Take it out after drying for 300 o C was calcined for 3 hours to obta...

Embodiment 2

[0035] Embodiment 2: the preparation of a kind of double oxide nanocomposite electrode material:

[0036] First weigh 1.19 grams of cobalt chloride hexahydrate and 0.075 grams of aluminum nitrate nonahydrate and dissolve them in a small beaker containing 30 ml of distilled water. After ultrasonication for 30 minutes, continue to add 2 ml of ammonia water drop by drop while stirring with a magnetic stirrer. , take out the magnet, transfer the mixed solution to a 50 ml stainless steel autoclave with a polytetrafluoroethylene liner, seal the autoclave, place it in an oven at 180 degrees Celsius, take it out after 12 hours, and naturally Cool to room temperature, centrifuge at 8,000 rpm for 5 minutes, wash with distilled water and ethanol three times each to obtain a precipitate, put the precipitate in a 60-degree oven, place it for 12 hours and take it out after drying, 300 o C was calcined for 3 hours to obtain the final product.

Embodiment 3

[0037] Embodiment 3: the preparation of a kind of oxide nano-electrode material:

[0038] First weigh 1.19 g of cobalt chloride hexahydrate and dissolve it in a small beaker containing 30 ml of distilled water. After ultrasonication for 30 minutes, while stirring with a magnetic stirrer, continue to add 2 ml of ammonia water drop by drop, take out the magnet, and mix The solution was transferred to a stainless steel autoclave with a polytetrafluoroethylene liner with a volume of 50 ml. The autoclave was sealed and placed in an oven at 180 degrees Celsius. After 12 hours, it was taken out, cooled naturally to room temperature, and heated at 8000 rpm. Speed per minute, centrifuge for 5 minutes, wash with distilled water and ethanol three times each to obtain a precipitate, put the precipitate in a 60-degree oven, place it for 12 hours and take it out after drying, 300 o C was calcined for 3 hours to finally obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com