Alternative R-134A refrigerant for vehicle and preparation method of refrigerant

A refrigerant and raw material technology, applied in chemical instruments and methods, heat exchange materials, sustainable manufacturing/processing, etc., can solve the problems of high drying and cleaning requirements of the refrigeration system, lack of environmental protection features, and unfavorable refrigeration systems. Achieve the effects of avoiding economic loss, good energy saving effect, and large latent heat of evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

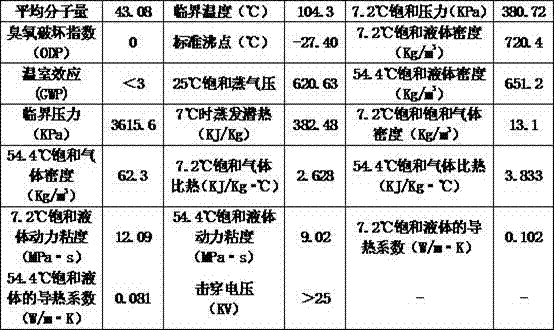

Image

Examples

Embodiment 1

[0031] A refrigerant that replaces R-134A for vehicles, which is made by fully mixing the following raw materials in parts by weight:

[0032] 48.58 parts of difluoromethane; 36.75 parts of propylene; 14.67 parts of trifluoroiodomethane.

[0033] Its preparation method is as follows:

[0034] S1. Detect the purity of difluoromethane, propylene, and trifluoroiodomethane raw materials respectively to ensure that the purity reaches more than 99.96wt, and set aside;

[0035] S2. Use propylene with a purity up to the standard in S1 as the cleaning reagent to clean the pressure vessel. The cleaning reagent is input into the pressure vessel with a high-pressure pump. The volume of the cleaning reagent accounts for about 3% of the volume of the pressure vessel. Shake the pressure vessel or stir the cleaning reagent in it. , fully cleaned, drain the propane after cleaning, and let it stand still to evaporate the residual propane, then the cleaning of the pressure vessel is completed; ...

Embodiment 2

[0040] A refrigerant for replacing R-134A used in vehicles is prepared by fully mixing the following raw materials in parts by weight: 42.56 parts of difluoromethane; 46.87 parts of propylene; and 10.57 parts of trifluoroiodomethane.

[0041] Its preparation method is identical with embodiment 1.

Embodiment 3

[0043] A refrigerant for substituting R-134A for vehicles is prepared by fully mixing the following raw materials in parts by weight: 39.67 parts of difluoromethane; 50.12 parts of propylene; and 10.21 parts of trifluoroiodomethane.

[0044] Its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com