Method for preparing adhesive ferrite magnetic powder

A ferrite magnet and coarse powder technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of increasing water and gas costs, complicated iron red production process, and long production cycle, etc., to achieve Effects of reducing drying gas consumption, reducing surface activity, and reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing bonded ferrite magnetic powder, specifically, the method comprises the following steps:

[0028] (1) A strontium-containing compound and / or a barium-containing compound is mixed with iron red to obtain a mixed material, and the mixed material is sintered to obtain a sintered material. Described iron red is high chloride iron red or low chloride iron red; The chlorine content of described high chloride iron red is 0.5-2.0wt.% (such as 0.5wt.%, 0.8wt.%, 0.9wt.%, 1.2wt.% %, 1.5wt.%, 1.8wt.% or 2.0wt.%); the chlorine content of the low chlorine iron red is less than 0.5wt.% (such as 0.01wt.%, 0.02wt.%, 0.05wt.%, 0.1wt.%, 0.15wt.%, 0.2wt.%, 0.3wt.%, 0.4wt.% or 0.45wt.%). The mixture is obtained by mixing iron red and strontium-containing compounds (such as strontium carbonate or strontium sulfate), the molar ratio of iron red and strontium-containing compounds is 5.7-5.9 (such as 5.7, 5.8 or 5.9), and / or the mixture It is obtai...

Embodiment 1

[0039] Perchlorferric iron red with a chlorine content of 0.8wt.% is weighed and mixed with strontium carbonate in a molar ratio of 5.7 to obtain a mixture, and the particle size is 3 μm according to the 0.3wt.% of the mixture amount, and zinc oxide with a purity of 99.5% is obtained. Strontium chloride is taken according to 2wt.% of the amount of the mixture, zinc oxide and strontium chloride are added to the mixture, stirred and mixed for 5 minutes, and then pre-sintered at 1050° C. for 2 hours to obtain a sintered material. Then, the obtained sintered material is ground into a coarse powder that can pass through a 60-mesh sieve with a pass-through ball mill, and then finely ground with a horizontal mixer for 1 hour to form a slurry with a particle size of 0.9 μm, and washed with water. The slurry was described until the pH value of the slurry was 8, and the slurry was dried at 200° C. for 1 hour for dehydration to obtain a fine powder. Then add 0.2wt.% ethylene glycol amine...

Embodiment 2

[0043] Example 2 was carried out in the same manner as Example 1, except that ferric red with a chlorine content of 2wt.% was weighed and mixed with strontium carbonate at a molar ratio of 5.7 to obtain a mixture.

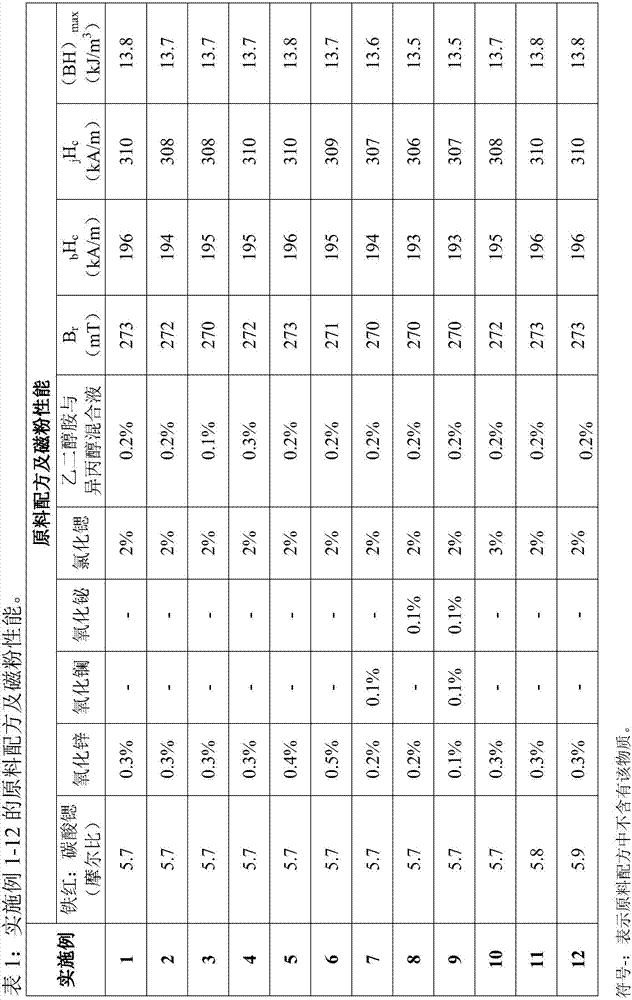

[0044] Examples 3-12 were carried out in basically the same manner as in Example 1, with the differences shown in Table 1 below.

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Remanent flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com