A 3D waterjet mosaic processing technology

A processing technology and mosaic technology, which is applied in the field of building decoration materials, can solve the problems of insufficient and missing three-dimensional mosaic aesthetics, and achieve the effect of high-tech added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

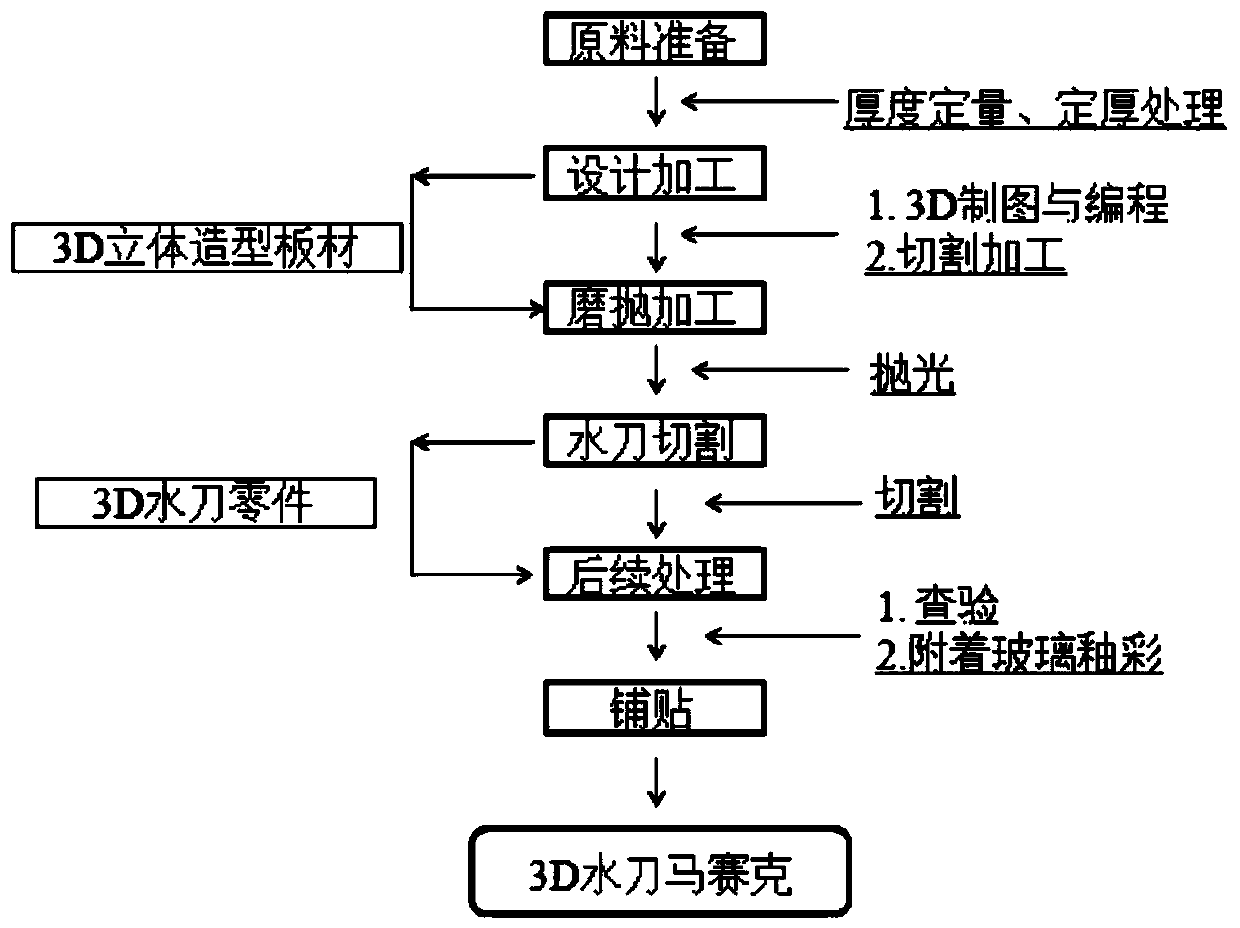

[0022] The specific implementation of this embodiment is shown in the flow chart of Figure 1. The raw material is marble, including raw material preparation, design processing, grinding and polishing processing, water jet cutting, subsequent processing, and paving procedures, wherein:

[0023] The raw material preparation process includes two steps of thickness quantification and thickness determination.

[0024] The design and processing process: 3D drawing and programming, after inputting the 3D programming program, use the engraving machine to cut and process the thickness-fixed plate in the raw material preparation process, and the cutter head of the engraving machine is fully automated according to the original path set by the program , Multi-angle three-dimensional cutting, processing the plate into a 3D three-dimensional shape plate.

[0025] The grinding and polishing process: the 3D three-dimensional shape plate obtained in the design and processing process is ground ...

Embodiment 2

[0033] The specific implementation of this embodiment is shown in the flow chart of Figure 1. The raw material is LAVA volcanic rock, including raw material preparation, design processing, grinding and polishing processing, water jet cutting, subsequent processing, and paving procedures, wherein:

[0034] The raw material preparation process includes two steps of thickness quantification and thickness determination.

[0035] The design and processing process: 3D drawing and programming, after inputting the 3D programming program, use the engraving machine to cut and process the thickness-fixed plate in the raw material preparation process, and the cutter head of the engraving machine is fully automated according to the original path set by the program , Multi-angle three-dimensional cutting, processing the plate into a 3D three-dimensional shape plate.

[0036] The grinding and polishing process: the 3D three-dimensional shape plate obtained in the design and processing proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com