Turning tool and machining method of outer nozzle ring

A processing method and outer ring technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of narrow metal liquid flow channels, workpiece defects, force impact, etc., to avoid economic losses, guarantee Processing content and precision, changing the effect of clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

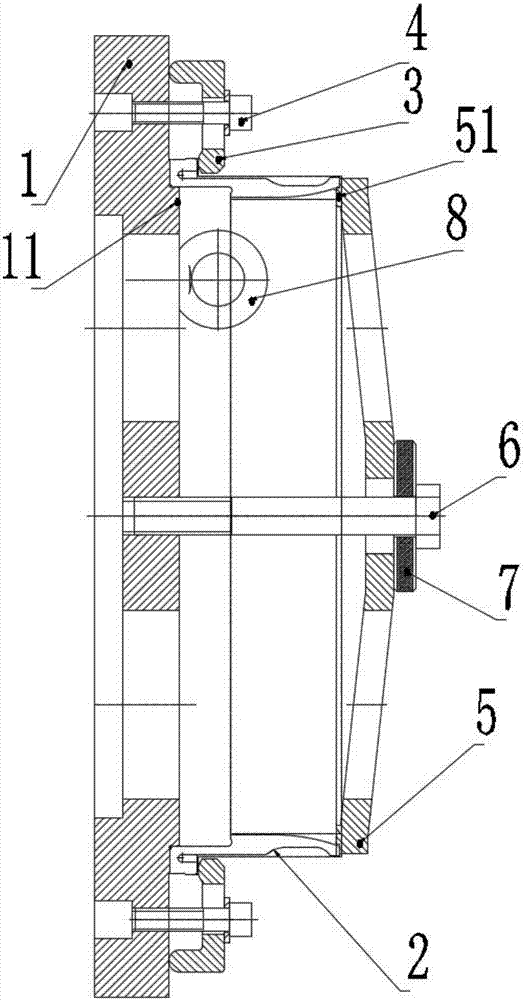

[0044] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

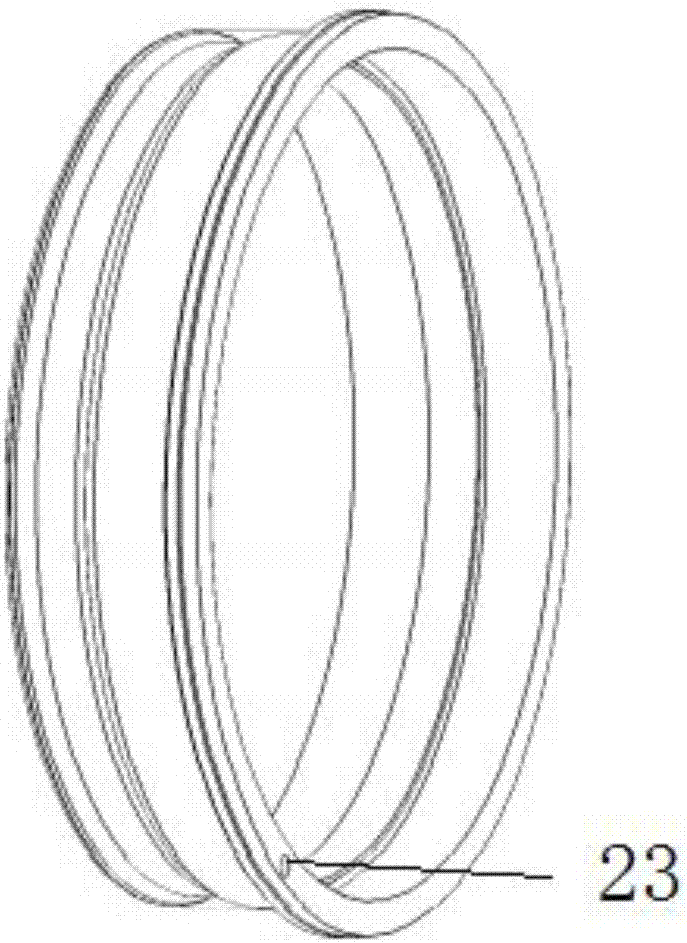

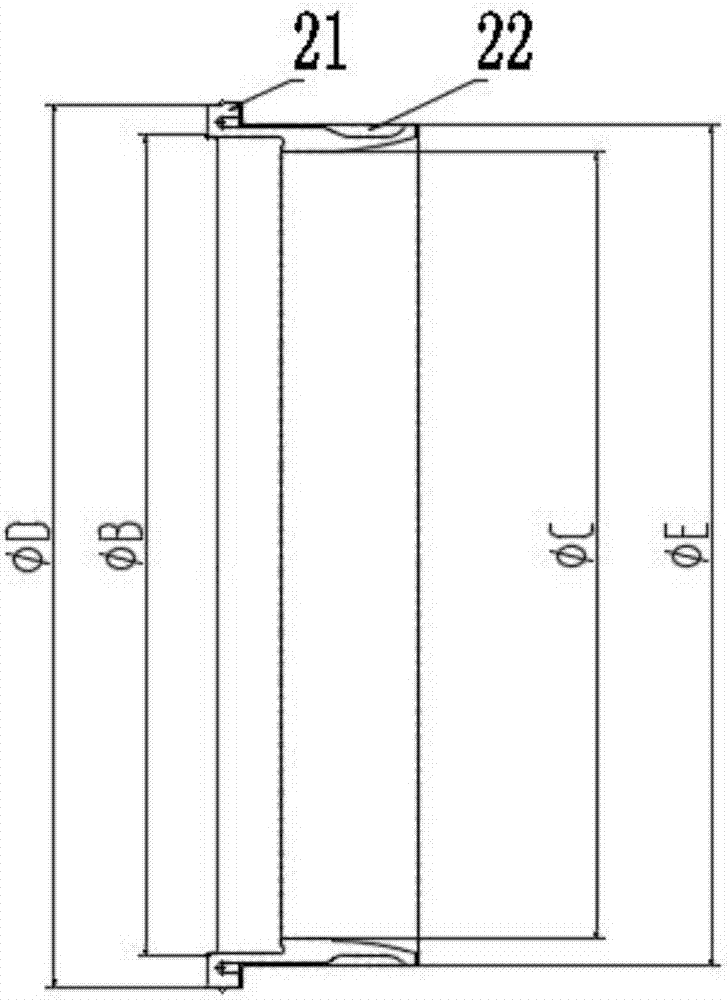

[0045] see Figure 1-Figure 3 , a kind of embodiment of the turning tool of nozzle outer ring, comprises base 1, and base 1 is provided with boss 11, is used for embedding the big end inner hole фB of nozzle outer ring 2, forms the pair of nozzle outer ring 2 Radial positioning, the base 1 is also provided with a plurality of detachable outer pressure plates 3, and the plurality of outer pressure plates 3 are arranged in a ring around the periphery of the boss 11, and are used to abut against the steps 21 at the big end of the outer ring 2 of the nozzle to form a pair of nozzles. For the axial positioning of the nozzle outer ring 2, the boss 11 is also provided with a detachable inner pressure plate 5, which is used to abut against the small end face of the nozzle outer ring 2 to form the axial positioning of the nozzle outer ring 2. In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com