Flexible conductor and preparation method thereof

A flexible conductive and sugar cube technology, applied in the field of conductors, can solve the problems of poor performance and cumbersome manufacturing process of flexible conductors, and achieve the effects of good stretchability, good flexibility, and solving cumbersome manufacturing processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation of embodiment 1 silicone rubber sponge

[0054] Mix liquid A and liquid B in the Ecoflex-0030 series products of Smooth-On Company at a mass ratio of 1:1, and stir with a mechanical stirrer for 1 min to obtain a uniformly mixed silicone rubber prepolymer, and then prepare the prepared too Immerse the sugar cube in the uniformly mixed silicone rubber prepolymer, place the mixture of the prepolymer and the sugar cube in a vacuum drying room, and use a mechanical pump to extract the air in the mixture. After 15 minutes, the prepolymer will stick to the Polymer sugar cubes were taken out and placed upright in a plastic petri dish filled with pre-prepared air-free silicone rubber prepolymer, ensuring that the top of the sugar cube was just not submerged, and then placed in a drum at 65°C Cured in an air oven for 1 hour, then took out the cured mixture, cut off the layer of silicone rubber sticking to the top of the sugar cube, put it into a plastic cup filled...

Embodiment 2

[0055] The preparation of embodiment 2 flexible conductors

[0056] Cut the height of the silicone rubber sponge prepared in Example 1 to 7-9mm, measure the length, width and height of the sponge and calculate it as volume V, and then use a 1mL syringe to inject gallium indium tin alloy into the silicon rubber sponge prepared in Example 1. In the hole of the rubber sponge, record the mass M of the injected gallium indium tin alloy at the same time, then squeeze the silicone rubber sponge to make the liquid alloy evenly distributed, repeat this process several times, and calculate the liquid gallium indium tin alloy in the silicone rubber sponge. Density ρ=M / V, and finally a three-dimensional interconnected conductive silicon rubber sponge filled with gallium indium tin alloys of different densities is obtained.

Embodiment 3

[0057] The performance test of embodiment 3 flexible conductor

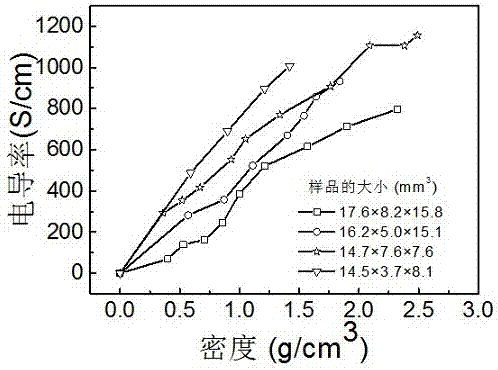

[0058] The relationship between conductivity and density ρ of flexible conductors

[0059] The conductivity of different shapes of liquid metal sponges (including: 17.6 mm*8.2 mm*15.8 mm, 16.2 mm*5.0 mm*15.1 mm, 14.7 mm*7.6 mm*7.6 mm and 14.5 mm*3.7 mm*8.1 mm) varies with The result of the change of the density ρ is as follows figure 1 As shown, it can be seen that the electrical conductivity of the liquid metal sponge has almost a linear relationship with its density ρ, and the electrical conductivity of the liquid metal silicone rubber sponge with different shapes increases with the increase of the density.

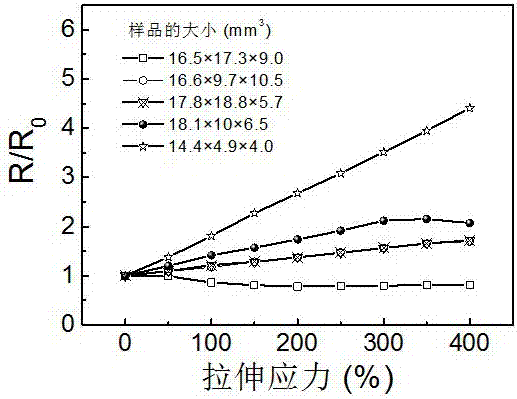

[0060] Resistance of flexible conductors of different shapes as a function of stretching ratio

[0061] The result is as figure 2 , showing the change in resistance of flexible conductors under different stretching ratios (0-400%), figure 2 , the density of liquid metal in each sponge is 2.0 g / cm 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com