An air-core reactor fault location circuit

An air-core reactor and fault location technology, applied in the field of electric power, can solve the problems of low detection sensitivity of air gap discharge in insulation, inability to determine the discharge position, and high signal-to-noise ratio, so as to improve the determination of the specific position of the discharge fault point and facilitate the fault. Diagnose and repair, calculate the effect of accurate structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

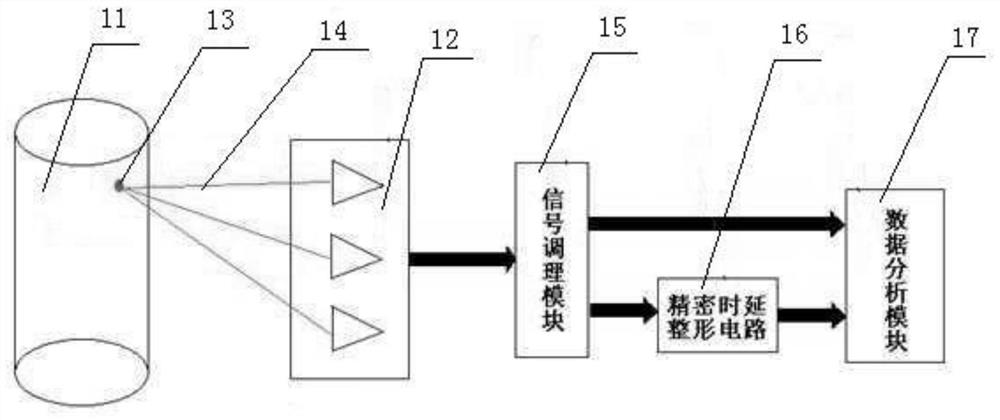

[0033] Such as Figure 1-3 As shown, the present invention includes an air-core reactor fault location circuit, including

[0034] The distributed probe 12 is used to couple the high-frequency electromagnetic wave signal 14 radiated from the fault point 13 of the air-core reactor 11 and transmit it to the signal conditioning module;

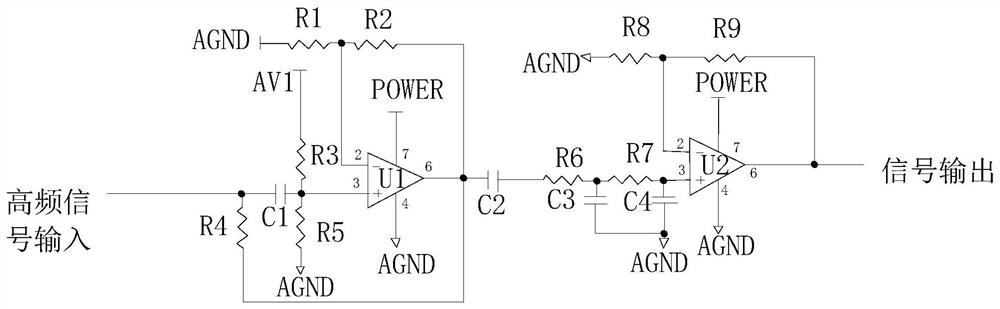

[0035] The signal conditioning module 15 extracts the weak high-frequency electromagnetic wave signal in the 100MHz-300MHz frequency band, amplifies the signal and transmits it to the precision delay shaping circuit and data analysis module;

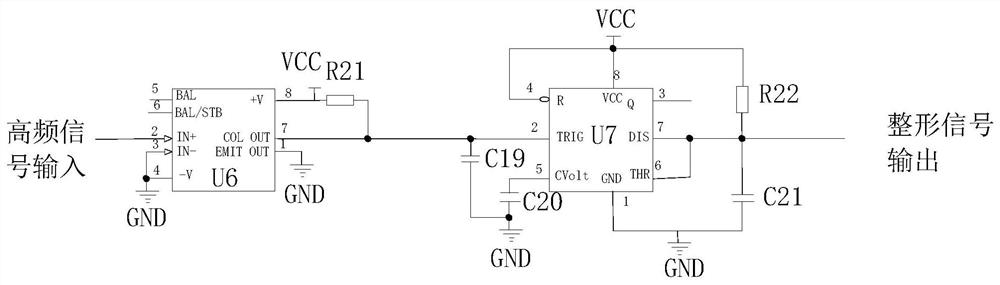

[0036]The precise time delay shaping circuit 16 modulates the transmitted high-frequency electromagnetic wave signal into a pulse signal with a rising edge of picosecond level, and then transmits it to the data analysis module;

[0037] The data analysis module 17 analyzes the high-frequency electromagnetic wave signal amplified by the signal conditioning module and the pulse signal modulated by the precis...

Embodiment 2

[0041] This embodiment is preferably as follows on the basis of Embodiment 1: the distributed probe is composed of three directional high-frequency antennas, each directional high-frequency antenna adopts a tapered structure, the material is gold-plated aluminum, and the directional high-frequency antenna can sense local Discharge high frequency signal. The probe in this solution is a passive probe, which does not need to supply power to the probe, and the passive probe works stably and economically. The directional high-frequency antenna in this solution can accurately receive the high-frequency electromagnetic waves emitted by the internal fault point of the air-core reactor, so as to accurately obtain the position of the insulation defect inside the air-core reactor.

[0042] The distance between the three directional high-frequency antennas is equal, and the distance can be adjusted arbitrarily to ensure that the measurement range of the distributed probe covers the entire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com