Position-sensitive anode detector and method of making the same

A position-sensitive anode and detector technology, which is applied in photometry, photometry, and instruments using electric radiation detectors, can solve problems such as small dynamic range, difficult processing of position-sensitive anodes, and low time resolution, and achieve Large dynamic range, compact structure, and good time characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

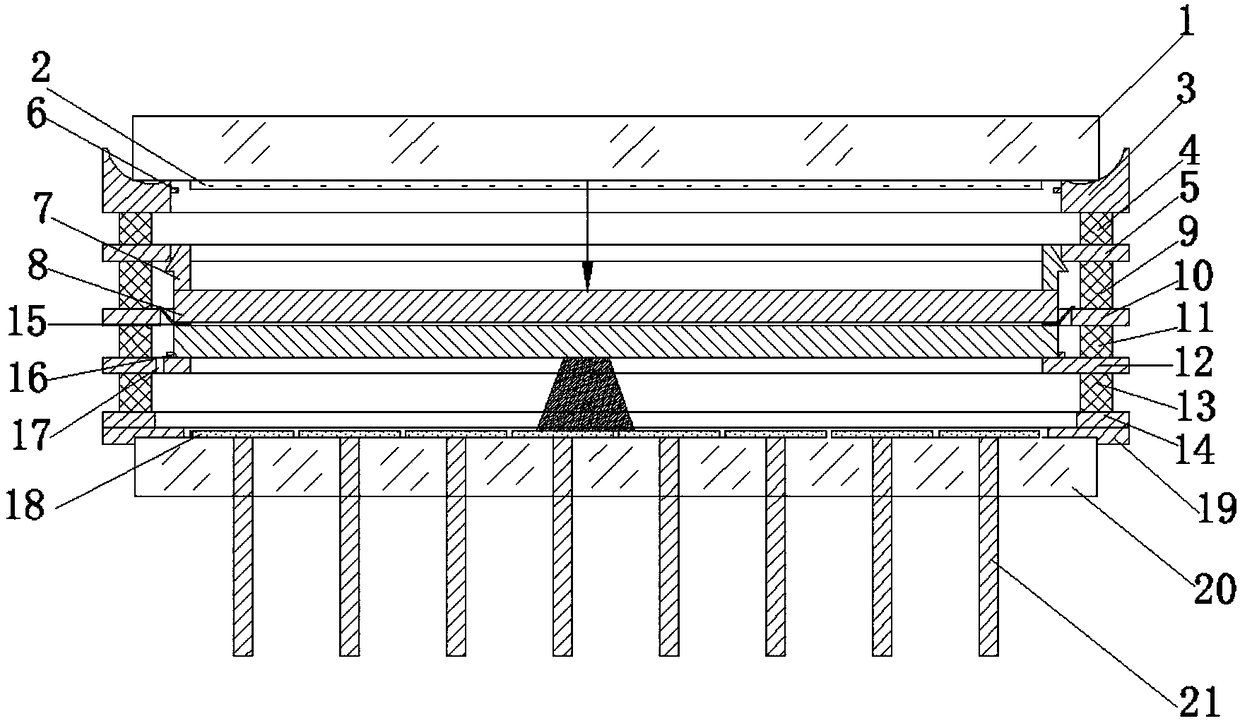

[0057] The effective working size of the position-sensitive anode detector of the present invention is 20x20mm~100x100mm, including a cathode window 1, a photocathode 2, an MCP electron multiplier 8, a retaining spring 7 (MCP fixing ring), a position-sensitive anode and a cermet tubular shell, The detector adopts a double proximity electron focusing structure, that is, the proximity distance between the cathode surface and the MCP input surface is 1~3mm, and the proximity distance between the MCP output surface and the electron receiving anode surface is 1~2mm, see figure 1 .

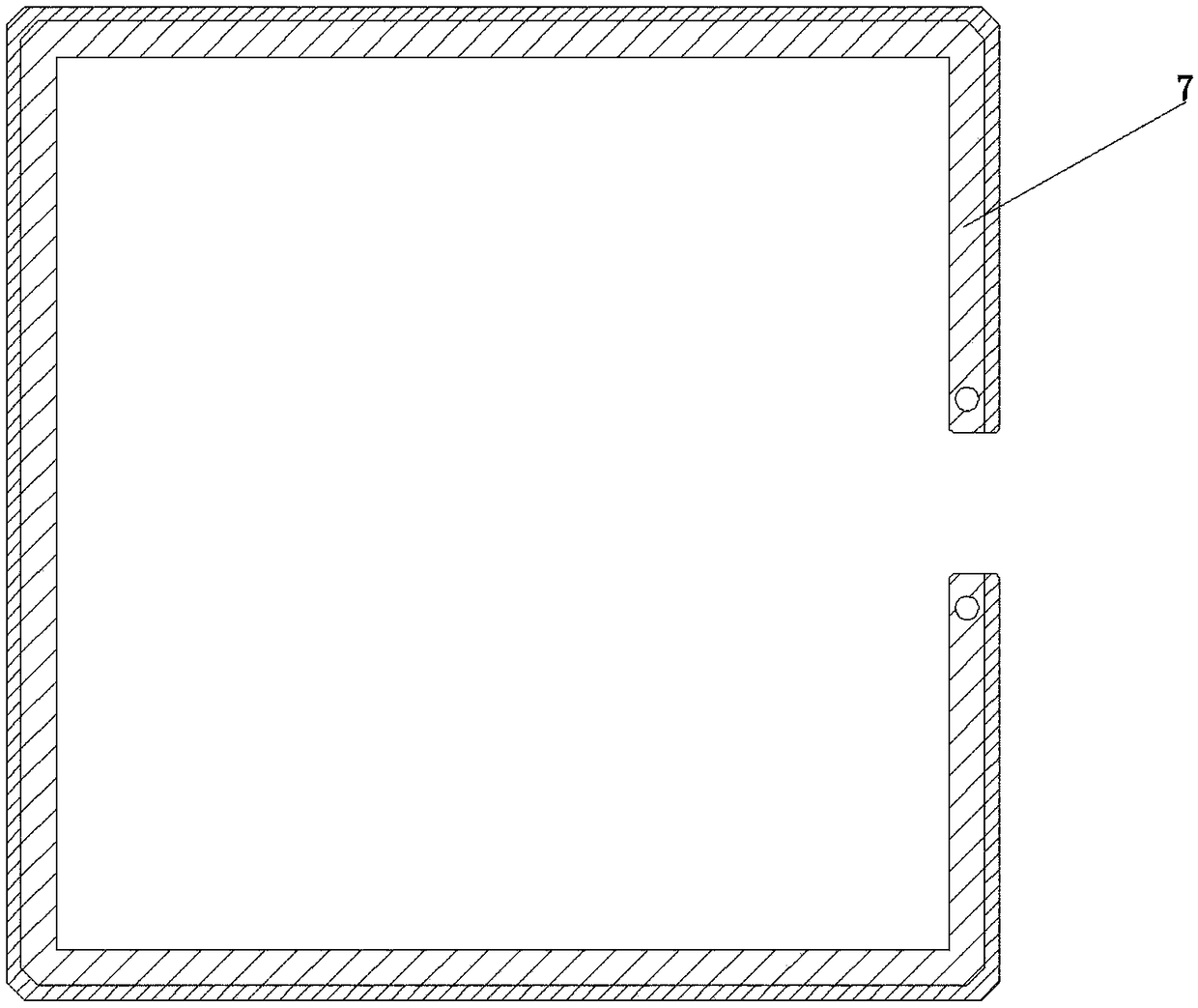

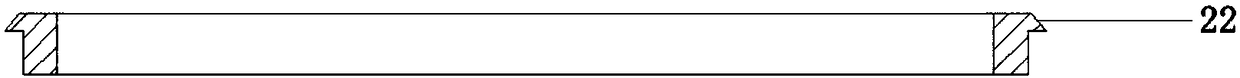

[0058] from figure 1 It can be seen that the metal-ceramic tubular shell has a square structure (not limited to a square shape, and can also be a circular structure), including a metal indium sealing groove 3, a first ceramic ring 4, a retainer positioning metal ring 5, and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com