Recovering method for copper-containing waste etching solution

A technology of waste etching solution and recovery method, which is applied in the direction of photography process, instrument, photography auxiliary process, etc., can solve the problems that the recovery of acid copper-containing waste etching solution cannot be handled separately, high efficiency, high environmental benefit, waste of resources and environment, etc. Realize the effect of resource utilization, efficient resource utilization, and good extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

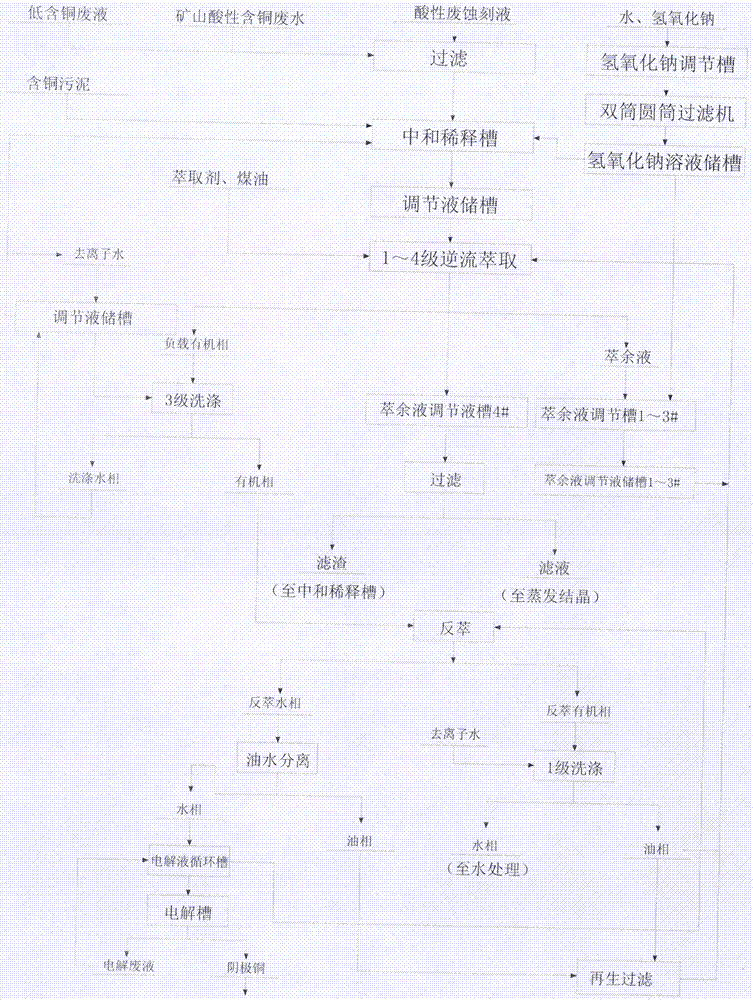

[0036] Such as figure 1 As shown, it shows a specific embodiment of the present invention, as shown in the figure, the copper-containing waste etching solution recovery method disclosed by the present invention includes the following steps:

[0037] (1) Send the copper-containing waste etching solution into the neutralization dilution tank after filtering, and adjust the pH to 2.6 to 3.5; the copper-containing waste etching solution at least includes copper-containing acidic waste etching solution; the pH of the extraction agent on the copper-containing etching solution According to the different concentration of copper ions in the etching solution and the number of extraction stages, adjust the pH value to about 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com