Hypotonic duct type oil deposit double-slug profile control agent and use method thereof

A profile control agent and oil reservoir technology, applied in the field of double-slug composite profile control agent in low-permeability pore-type reservoirs, can solve the problems of reducing the sweep efficiency of injected water, difficulty adapting to reservoir complexity, and low water flooding sweep efficiency, etc. problems, to achieve the effects of inhibiting the formation of dead oil zones, improving hydrophilicity, and improving plugging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

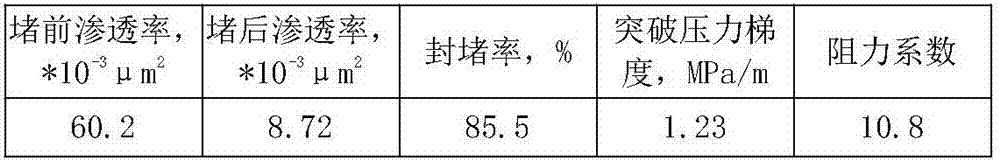

Embodiment 1

[0036] 1. The method of using the profile control agent: (1) First, carry out oxygen exposure treatment on the prepared water to reduce the dissolved oxygen content in the prepared water to below 3mg / L; (2) Add the agent to the prepared water at a constant speed at a temperature of 15°C. Stir for 4 hours to obtain the profile control agent; (3) After the preparation is completed, inject the profile control agent directly into the rock core.

[0037] 2. Prepare water, adjust the salinity to 500mg / L by adding NaCl to the distilled water, so as to simulate the source water used in production.

[0038] 3. The specific application dosage is:

[0039] Slug A: Sodium silicate, partially hydrolyzed polyacrylamide, sodium hexametaphosphate, sodium sulfite, salicylic acid, aluminum citrate with a mass ratio of 1.5%: 0.1%: 0.3%: 0.5%: 0.2%: 0.2%, and the rest The component is the preparation water.

[0040] Slug B: The mass ratio of coconut oil fatty acid diethanolamide and sodium dodecy...

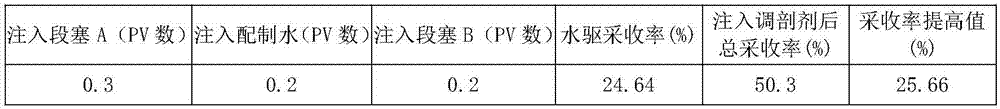

Embodiment 2

[0067] 1. The method of using the profile control agent: (1) First, carry out oxygen exposure treatment on the prepared water to reduce the dissolved oxygen content in the prepared water to below 3mg / L; (2) Add the agent to the prepared water at a constant speed at a temperature of 35°C. Stir for 5 hours to obtain the profile control agent; (3) After the preparation is completed, inject the profile control agent directly into the rock core.

[0068] 2. Prepare water, adjust the salinity to 8000mg / L by adding NaCl to the distilled water, to simulate the oil field sewage used in actual production.

[0069] 3. The specific application dosage is:

[0070] Slug A: Sodium silicate, partially hydrolyzed polyacrylamide, sodium hexametaphosphate, sodium sulfite, salicylic acid, aluminum citrate with a mass ratio of 1%: 0.05%: 0.2%: 0.4%: 0.1%: 0.15%, and the rest The component is the preparation water.

[0071] Slug B: The mass ratio of coconut oil fatty acid diethanolamide and sodiu...

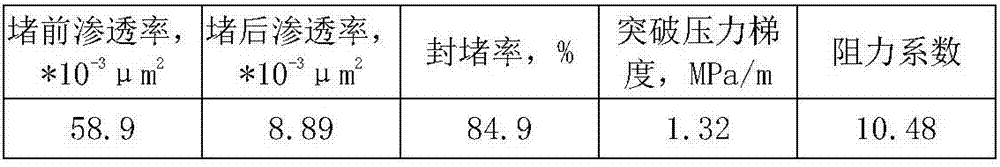

Embodiment 3

[0098] 1. The method of using the profile control agent: (1) First, carry out oxygen exposure treatment on the prepared water to reduce the dissolved oxygen content in the prepared water to below 3mg / L; (2) Add the agent to the prepared water at a temperature of 55°C, Stir for 6 hours to obtain the profile control agent; (3) After the preparation is completed, inject the profile control agent directly into the rock core.

[0099] 2. To prepare water, adjust the degree of salinity by adding soluble salts to the distilled water, and the final degree of salinity is 35000mg / L, which is used to simulate the oilfield sewage used in actual production.

[0100] 3. The specific application dosage is:

[0101] Slug A: Sodium silicate, partially hydrolyzed polyacrylamide, sodium hexametaphosphate, sodium sulfite, salicylic acid, aluminum citrate with a mass ratio of 2%: 0.15%: 0.4%: 0.6%: 0.3%: 0.25%, and the rest The component is the preparation water.

[0102] Slug B: The mass ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com