TPV for vehicle air conditioner pipe members

A low-odor and mixture technology, applied in the TPV field of automotive air-conditioning pipe fittings, can solve problems such as unsatisfactory mechanical properties, and achieve the effects of reducing odor and TVOC content, using environmentally friendly materials, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

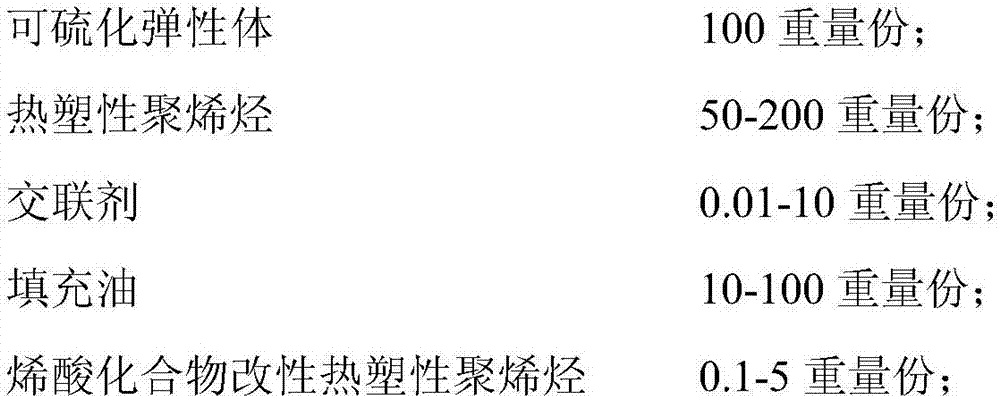

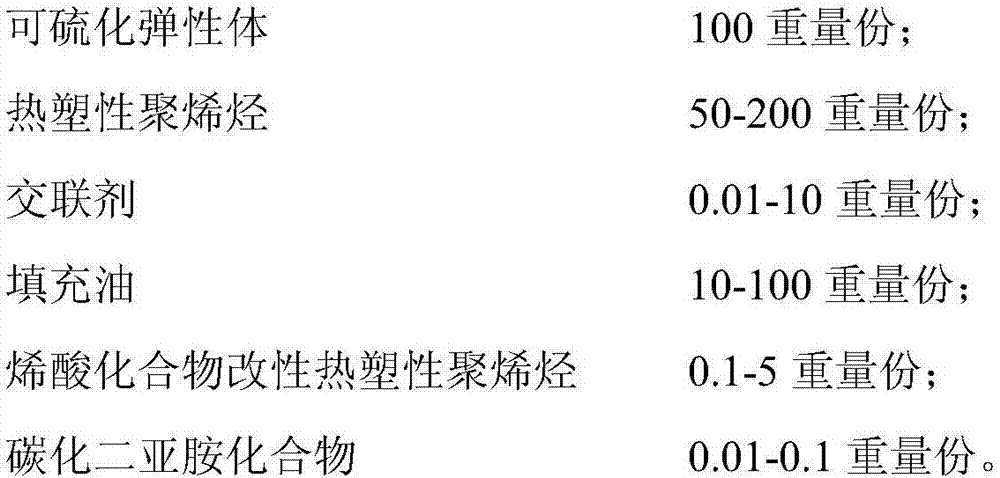

Method used

Image

Examples

Embodiment 1

[0046] 100 parts by weight of vulcanizable elastomer (U.S. DuPont NDR 2744), 70 thermoplastic polyolefin (ExxonMobil PP 7032KN), 1 part by weight of MAH graft modified polypropylene (ExxonMobil PP7032KN, grafting ratio 3wt%), weighed and poured into a blender, stirring evenly. Then add 3 parts by weight of cross-linking agent, 1.5 parts by weight of stannous chloride, 1 part by weight of zinc oxide, 0.5 parts by weight of stabilizer, 2 parts by weight of zinc stearate, pour into a stirrer and stir evenly. The mixed material is added in the hopper of the twin-screw extruder, the extender oil of 100 parts by weight, the plasticizer trioctyl trimellitate of 5 parts by weight, the bis(trimethylsilyl) of 0.02 parts by weight The carbodiimide mixture is fed into the extruder from the plasticizing section of the extruder through a liquid metering pump, melted and blended, extruded and granulated to form a composite material. Among them, the temperature settings of each heating zone ...

Embodiment 2

[0048] 100 parts by weight of vulcanizable elastomer (U.S. DuPont NDR 2744), 70 thermoplastic polyolefins (ExxonMobil PP 7032KN), 1 part by weight of acrylic acid graft modified polypropylene (ExxonMobil PP 7032KN, grafted Rate 2wt%), weighed and poured into a blender, stirred evenly. Then add 3 parts by weight of cross-linking agent, 1.5 parts by weight of stannous chloride, 1 part by weight of zinc oxide, 0.5 parts by weight of stabilizer, 2 parts by weight of zinc stearate, pour into a stirrer and stir evenly. The mixed material is added in the hopper of the twin-screw extruder, the extender oil of 100 parts by weight, the plasticizer trioctyl trimellitate of 5 parts by weight, the bis(trimethylsilyl) of 0.03 parts by weight The carbodiimide mixture is fed into the extruder from the plasticizing section of the extruder through a liquid metering pump, melted and blended, extruded and granulated to form a composite material. Among them, the temperature settings of each heati...

Embodiment 3

[0050] 100 parts by weight of vulcanizable elastomer (U.S. DuPont NDR 2744), 70 thermoplastic polyolefin (ExxonMobil PP 7032KN), 1 part by weight of MAH graft modified polypropylene (ExxonMobil PP7032KN, grafting ratio 5wt%), weighed and poured into a blender, stirring evenly. Then add 3 parts by weight of cross-linking agent, 1.5 parts by weight of stannous chloride, 1 part by weight of zinc oxide, 0.5 parts by weight of stabilizer, 2 parts by weight of zinc stearate, pour into a stirrer and stir evenly. The mixed material is added in the hopper of twin-screw extruder, the extender oil of 100 parts by weight, the plasticizer trioctyl trimellitate of 5 parts by weight, the two (trimethylsilyl) of 0.08 parts by weight The carbodiimide mixture is fed into the extruder from the plasticizing section of the extruder through a liquid metering pump, melted and blended, extruded and granulated to form a composite material. Among them, the temperature settings of each heating zone of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com