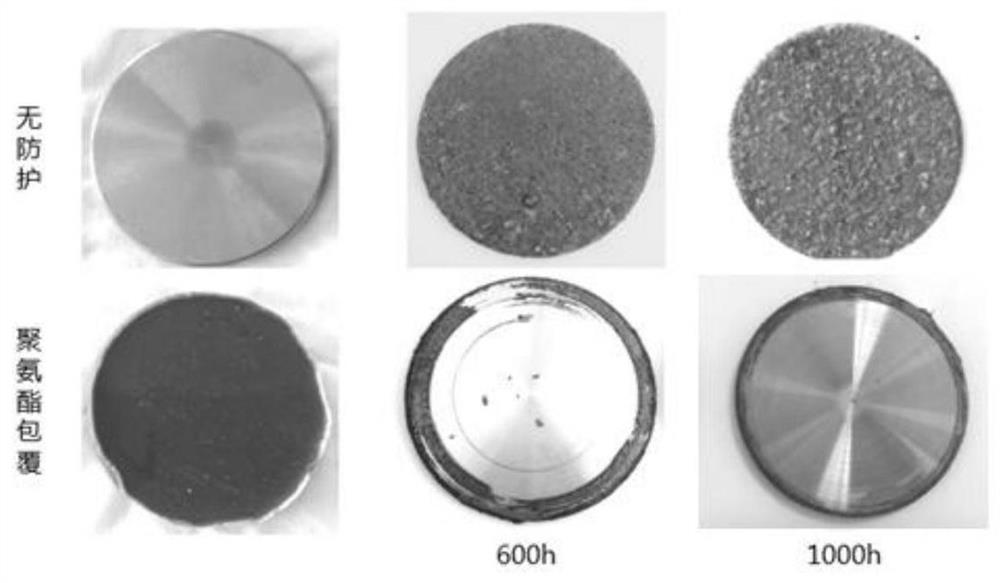

Anti-vibration and anti-corrosion polyurethane grouting composite material, preparation method and application

A technology of combining materials and polyurethane, applied in the field of polyurethane materials, can solve problems such as high price, and achieve the effects of reducing investment, convenient construction and reducing wave grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Preparation of component A: weigh polyether polyol, chain extender, antioxidant, leveling agent, glass beads and color paste into the reaction kettle, stir and heat. Vacuum dehydration and degassing under MPa conditions for 45 minutes, lower the temperature to 60-80°C, add amine catalysts and organic tin catalysts, continue to stir and vacuumize for 20-30 minutes, and control the water content of the mixture to less than 0.05%, stop heating and stirring, and start filling.

[0042] Preparation of component B: Weigh the isocyanate and polyol into the reaction kettle, stir and heat, react at 80-90°C for 3-4h, stop heating and stirring and start filling.

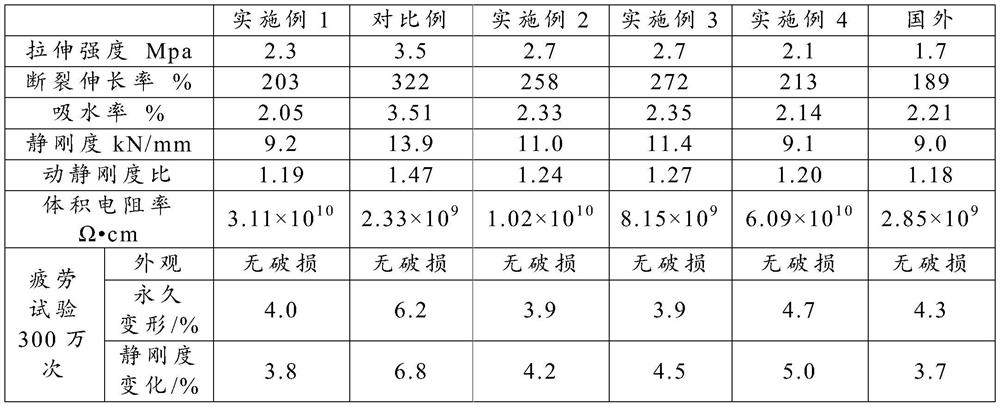

Embodiment 1

[0045] Component A: two kinds of polyoxypropylene with a number average molecular weight of 4000-6000 and a functionality of 3 Triol: 75%, chain extender 1,3-propanediol: 8%, chain extender 4,4ˊ-methylene Bis(2,6-diisopropylaniline): 5%, antioxidant 1010: 1%, amine catalyst triethylenediamine: 0.02%, organotin catalyst dibutyltin dilaurate: 0.01%, glass beads : 10%, modified polysiloxane leveling agent: 0.5%, color paste: 0.47%;

[0046] Component B: diphenylmethane diisocyanate: 40%, two polyoxypropylene diols with a number average molecular weight of 1000-2000 and a functionality of 2: 60%.

[0047] When in use, component A and component B are mixed and stirred evenly at 25-40°C according to the weight ratio of 1:0.7, then poured directly on the corresponding part of the track foundation, and cured at room temperature for 2 hours to form.

Embodiment 2

[0053] Component A: two kinds of polyoxypropylene with a number average molecular weight of 4000-6000 and a functionality of 3 Triol: 85%, chain extender 1,3-propanediol: 4%, chain extender 4,4ˊ-methylene Bis(2,6-diisopropylaniline): 4%, antioxidant 1010: 1%, amine catalyst triethylenediamine: 0.05%, organotin catalyst dibutyltin dilaurate: 0.02%, glass beads : 5%, modified polysiloxane leveling agent: 0.5%, color paste: 0.43%;

[0054] Component B: diphenylmethane diisocyanate: 30%, two polyoxypropylene diols with a number average molecular weight of 1000-2000 and a functionality of 2: 70%.

[0055] When in use, component A and component B are mixed and stirred evenly at 25-40°C according to the weight ratio of 1:0.6, then directly poured on the corresponding part of the track foundation, and cured at room temperature for 2 hours to form.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com