Polycarboxylate superplasticizer, preparation method thereof and cement mixture

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of concrete admixture and polycarboxylic acid water reducing agent, can solve the problems of poor appearance, poor workability, and high air-entraining content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

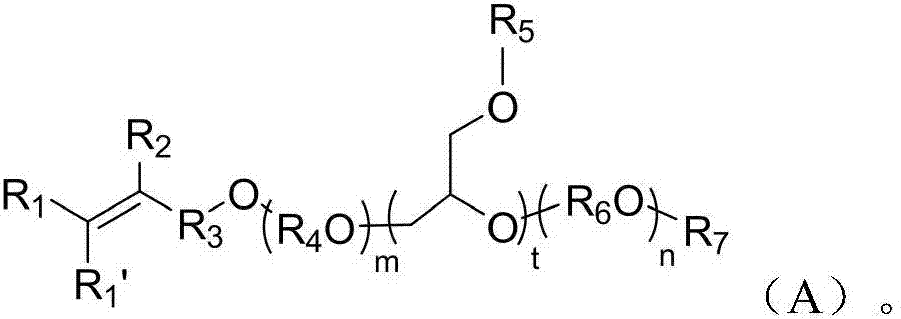

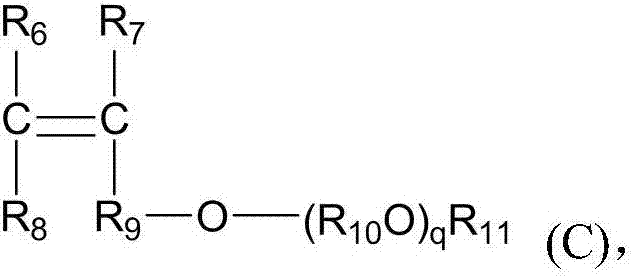

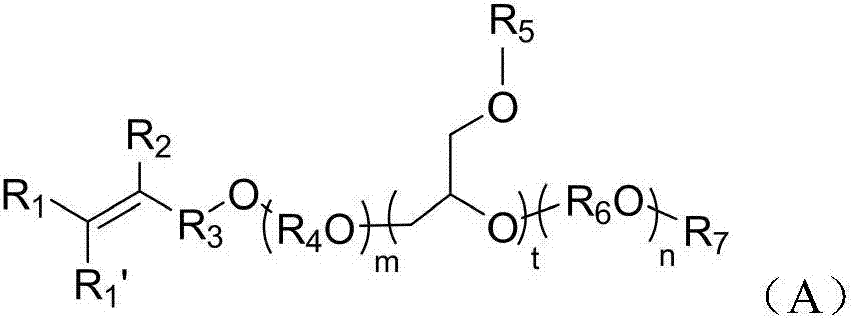

Method used

Image

Examples

Embodiment 1

[0078] 1.1 Preparation of monomer (A-1#)

[0079] Put 215 parts of dimethylallyl alcohol in a three-necked flask equipped with a nitrogen protection device, a thermometer and a stirrer, add 3 parts of NaH powder, quickly replace with nitrogen, turn on the heating, stir and raise the temperature to 90°C, and then add to the flask 310 parts of butyl glycidyl ether were slowly added dropwise at a medium and uniform speed, the reaction temperature was controlled to 90°C, the dropping time was 120 minutes, after the dropping was completed, the temperature was kept for 2 hours, and the intermediate 1 was obtained by cooling.

[0080] Add 416 parts of the above-mentioned synthetic intermediate to the autoclave, add 7.0 parts of NaH powder, replace with nitrogen, and then, while stirring, evacuate the reactor, turn on the heating, and start to slowly pass into the reactor after the temperature reaches 120°C 970 parts of ethylene oxide were polymerized and the temperature was maintained at ...

Embodiment 2

[0086] 2.1 Preparation of monomer (A-2#)

[0087] Put 300 parts of dimethylallyl alcohol in a three-necked flask equipped with a nitrogen protection device, a thermometer and a stirrer, add 4.5 parts of NaH powder, quickly replace with nitrogen, turn on the heating, stir and raise the temperature to 100°C, then add to the flask Add 744 parts of butyl glycidyl ether slowly at a medium and uniform speed, control the reaction temperature to 100°C, and add the time for 180 minutes. After the addition, keep it for 2 hours and cool to obtain Intermediate 1.

[0088] Add 500 parts of the above-mentioned synthesized intermediate to the autoclave, replace with nitrogen, then evacuate the reactor under stirring, turn on the heating, and then slowly pass 993 parts of ethylene oxide into the reactor after the temperature is raised to 120°C Carry out the polymerization reaction, maintain the temperature at 120° C. and the pressure at a relatively constant value of about 0.3 MPa, until all ethyl...

Embodiment 3

[0094] 3.1 Preparation of monomer (A-3#)

[0095] Place 403 parts of dimethylallyl alcohol in a three-necked flask equipped with a nitrogen protection device, a thermometer and a stirrer, add 3.4 parts of NaH powder, quickly perform nitrogen replacement, turn on the heating, stir and raise the temperature to 100°C, and then add to the flask Add 325 parts of butyl glycidyl ether slowly at a medium uniform speed, control the reaction temperature to 100°C, and add the time for 180 minutes. After the addition, keep it for 2 hours and cool to obtain Intermediate 1.

[0096] Add 360 parts of the above synthesized intermediate to the autoclave, replace with nitrogen, then evacuate the reactor while stirring, turn on the heating, and then slowly pour 1035 parts of ethylene oxide into the reactor. Carry out the polymerization reaction, maintaining the temperature at 120°C and the pressure relatively constant at about 0.4 MPa, until all ethylene oxide is added to the reactor, and the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com