Method for treating methylene blue wastewater

A methylene blue and waste water technology, which is applied in water/sewage treatment, chemical instruments and methods, neutralized water/sewage treatment, etc., can solve the problems of flocculant being difficult to achieve the desired effect, high treatment cost and high price, and achieve decolorization effect. Remarkable, simple treatment process, convenient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

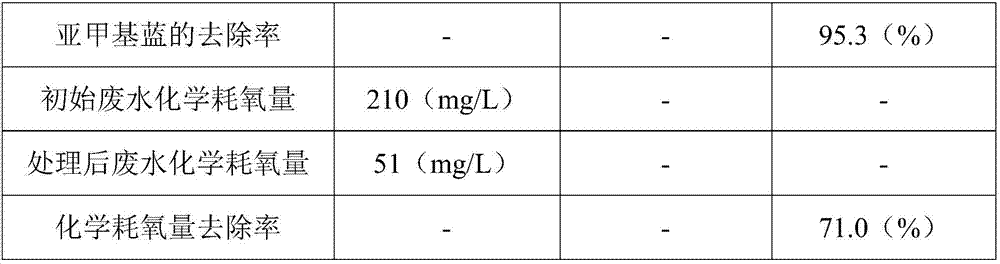

Embodiment 1

[0034] A method for processing methylene blue wastewater, comprising the following steps:

[0035] (1) get the methylene blue waste water 80ml that concentration is 100mg / L and place in the beaker;

[0036](2) adding concentration to the solution that step (1) obtains earlier is that 40g / L tannic acid aqueous solution 0.3ml and concentration are 0.4ml of 15g / L magnesium sulfate aqueous solution, under room temperature, stir 30s with the rotating speed of 150r / min, mix Uniformly, the dye aqueous solution is obtained;

[0037] (3) Adjust the pH of the aqueous dye solution obtained in step (2) to 9 with a 40% sodium hydroxide (NaOH) aqueous solution, stir for 30 seconds at a speed of 150 r / min, and form stable blue granular flocculation in the solution thing;

[0038] (4) in the aqueous solution with blue granular floc that step (3) obtains again, add ferric oxide (Fe 3 o 4 ) powder 0.1g and a concentration of 920g / L ferric chloride (Fecl 3 ) aqueous solution 0.05ml, then us...

Embodiment 2

[0042] A method for processing methylene blue wastewater, comprising the following steps:

[0043] (1) Take 80ml of methylene blue aqueous solution with a concentration of 100mg / L and place it in a beaker.

[0044] (2) to the solution that step (1) obtains earlier, adding concentration is that 40g / L tannic acid aqueous solution 0.3ml and concentration are 0.4ml of 15g / L magnesium sulfate aqueous solution, under room temperature, stir 30s with the rotating speed of 200r / min, mix Uniformly, the dye aqueous solution is obtained.

[0045] (3) Regulate the pH of the aqueous dye solution obtained in step (2) to 9-10 with a 40% NaOH aqueous solution, stir at a speed of 200r / min for 30s, and form stable blue granular flocs in the solution.

[0046] (4) in the aqueous solution that step (3) obtains again, add ferric oxide (Fe 3 o 4 ) powder 0.1g and a concentration of 920g / L ferric chloride (Fecl 3 ) aqueous solution 0.05ml, then use 40% sodium hydroxide (NaOH) to adjust the pH to ...

Embodiment 3

[0057] A method for processing methylene blue wastewater, comprising the following steps:

[0058] (1) 80ml of methylene blue aqueous solution with a concentration of 50mg / L is placed in a beaker;

[0059] (2) In the solution that step (1) obtains earlier, adding concentration is that 40g / L tannic acid aqueous solution 0.3ml and concentration are 0.4ml of 15g / L magnesium sulfate aqueous solution, under room temperature, stir 30s with the rotating speed of 150-200r / min , mixed uniformly to obtain an aqueous dye solution;

[0060] (3) Adjust the pH of the aqueous dye solution obtained in step (2) to 9-10 with a 40% sodium hydroxide (NaOH) aqueous solution, stir at a speed of 150-200r / min for 30s, and form a stable blue color in the solution After granular flocs;

[0061] (4) in the aqueous solution that step (3) obtains again, add ferric oxide (Fe 3 o 4 ) powder 0.1g and a concentration of 920g / L ferric chloride (Fecl 3 ) aqueous solution of 0.05ml, and then use 40% NaOH to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com