Preparation method and application of manganese doped magnetic nickel oxide

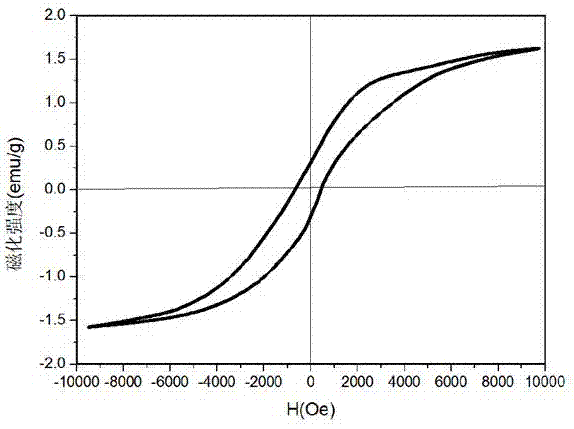

A nickel oxide and manganese doping technology, which is applied in the direction of nickel oxide/nickel hydroxide, inorganic materials, etc., can solve the problems of uneven particle size, low saturation magnetization, complex process, etc. The effect of good appearance and simple equipment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

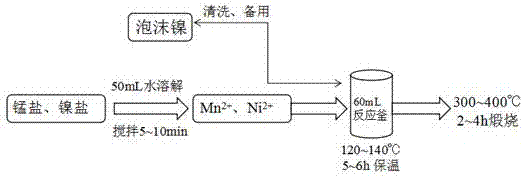

[0025] A preparation method of manganese-doped magnetic nickel oxide, comprising the following steps:

[0026] (1) Take the foamed nickel sheet, put it into 6 M hydrochloric acid and ultrasonically clean it for 10-15 minutes, then use ethanol to ultrasonically clean it for 10-15 minutes, and finally use deionized water to ultrasonically clean it 2-3 times, each cleaning time is 5-10 minutes, Obtain the nickel foam sheet with metallic luster, standby;

[0027] (2) Weigh 0.1mol of manganese nitrate and 0.01mol of nickel chloride respectively, dissolve them in 50 mL of water, stir for 5-10min, and obtain a purple transparent clear liquid;

[0028] (3) Put nickel foam into a 60 mL polytetrafluoroethylene reaction kettle, then add the purple clear solution into the reaction kettle, put it in a horizontal blast drying oven, react at 120°C for 8h, and then heat it at 10°C Cool to room temperature at a rate of 1 / min, take out the purple nickel foam sheet, wash it with water and ethan...

Embodiment 2

[0032] A preparation method of manganese-doped magnetic nickel oxide, comprising the following steps:

[0033] (1) Take the foamed nickel sheet, put it into 6 M hydrochloric acid and ultrasonically clean it for 10-15 minutes, then use ethanol to ultrasonically clean it for 10-15 minutes, and finally use deionized water to ultrasonically clean it 2-3 times, each cleaning time is 5-10 minutes, Obtain the nickel foam sheet with metallic luster, standby;

[0034] (2) Weigh 0.08mol manganese chloride and 0.01mol nickel chloride respectively, dissolve them in 50 mL water, stir for 5-10min, and obtain a purple transparent clear liquid;

[0035] (3) Put nickel foam into a 60 mL polytetrafluoroethylene reaction kettle, then add the purple clear solution into the reaction kettle, put it in a horizontal blast drying oven, react at 130°C for 5 h, and then use 10 Cool to room temperature at the rate of ℃ / min, take out the purple nickel foam sheet, wash it with water and ethanol 2~3 times,...

Embodiment 3

[0039] A preparation method of manganese-doped magnetic nickel oxide, comprising the following steps:

[0040] (1) Take the foamed nickel sheet, put it into 6 M hydrochloric acid and ultrasonically clean it for 10-15 minutes, then use acetone to ultrasonically clean it for 10-15 minutes, and finally use deionized water to ultrasonically clean it for 2-3 times, each cleaning time is 5-10 minutes, Obtain the nickel foam sheet with metallic luster, standby;

[0041] (2) Weigh 0.06mol of manganese nitrate and 0.01mol of nickel nitrate respectively, dissolve them in 50 mL of water, stir for 5-10min, and obtain a purple transparent clear liquid;

[0042] (3) Put nickel foam into a 60 mL polytetrafluoroethylene reaction kettle, then add the purple clear solution into the reaction kettle, put it in a horizontal blast drying oven, and react at 140°C for 6h, then at 10°C Cool to room temperature at a rate of 1 / min, take out the purple nickel foam sheet, wash it with water and ethanol 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com