Multifunctional integrated manufacturing workbench for wire harness

An integrated wire harness and multi-functional technology, applied in the direction of workbench, manufacturing tools, etc., can solve the problems that are not conducive to the agile production of complex wire harnesses, the inability to realize wire harness detection, and the inability to use wire harnesses, so as to improve accuracy and flexibility, The effect of improving utilization rate and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

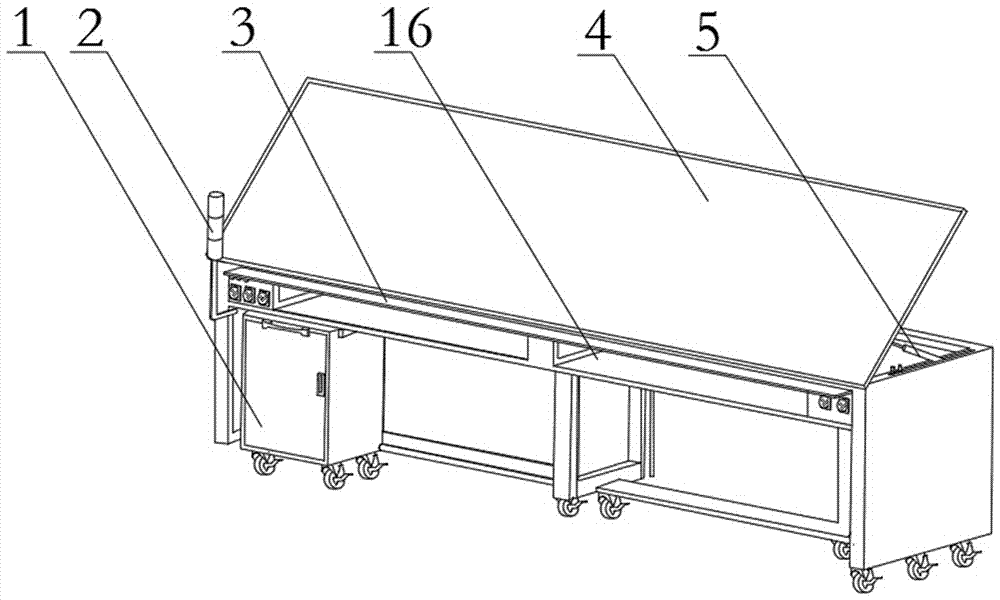

[0029] combined with figure 1 , attached figure 2 , attached image 3 , attached Figure 4As shown, a multifunctional function integrated wiring harness manufacturing workbench of the present invention is characterized in that it includes a support platform 14, and the bottom of the support platform 14 is provided with a roller 9, which facilitates the movement of the support platform, and the top of the support platform 14 A hydraulic support rod 5 is provided, and a wire harness plate 4 is arranged on the hydraulic support rod 5. The hydraulic support rod 5 controls the angle between one long side of the wire harness plate 4 and the support table 14, and adjusts the angle of the support table 14 according to the processing requirements of different wire harnesses. , to facilitate the manufacture of wire harnesses, the wire harness plate 4 is equidistantly provided with pin through holes 15, and the pin through holes 15 are convenient for measuring the size of the finished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com