Intelligent robot with grading quality inspection function

A robotic and functional technology, applied in sorting, manipulators, manufacturing tools, etc., can solve problems such as product performance testing, corporate reputation impact, buyer inconvenience, etc., to avoid program confusion, improve efficiency, and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

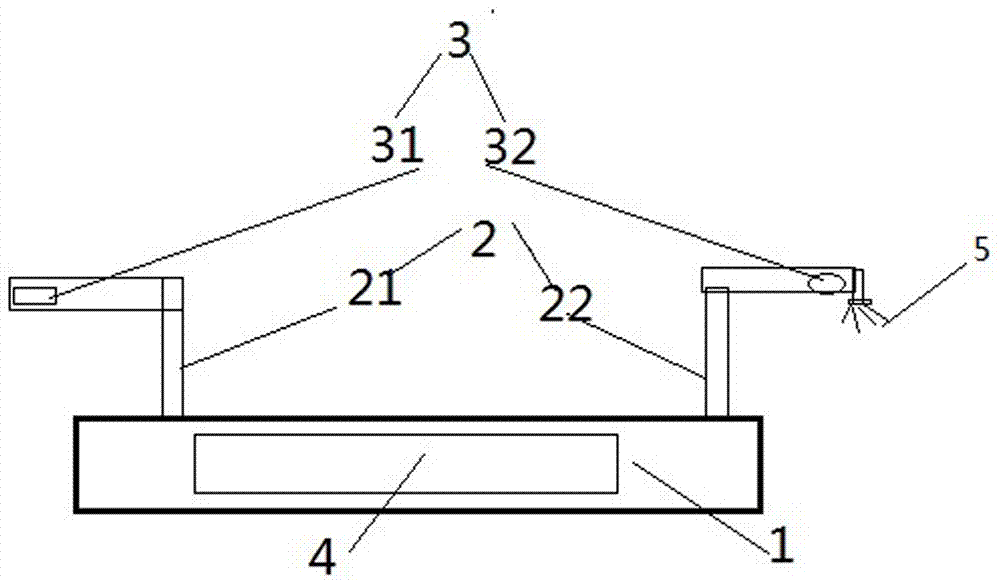

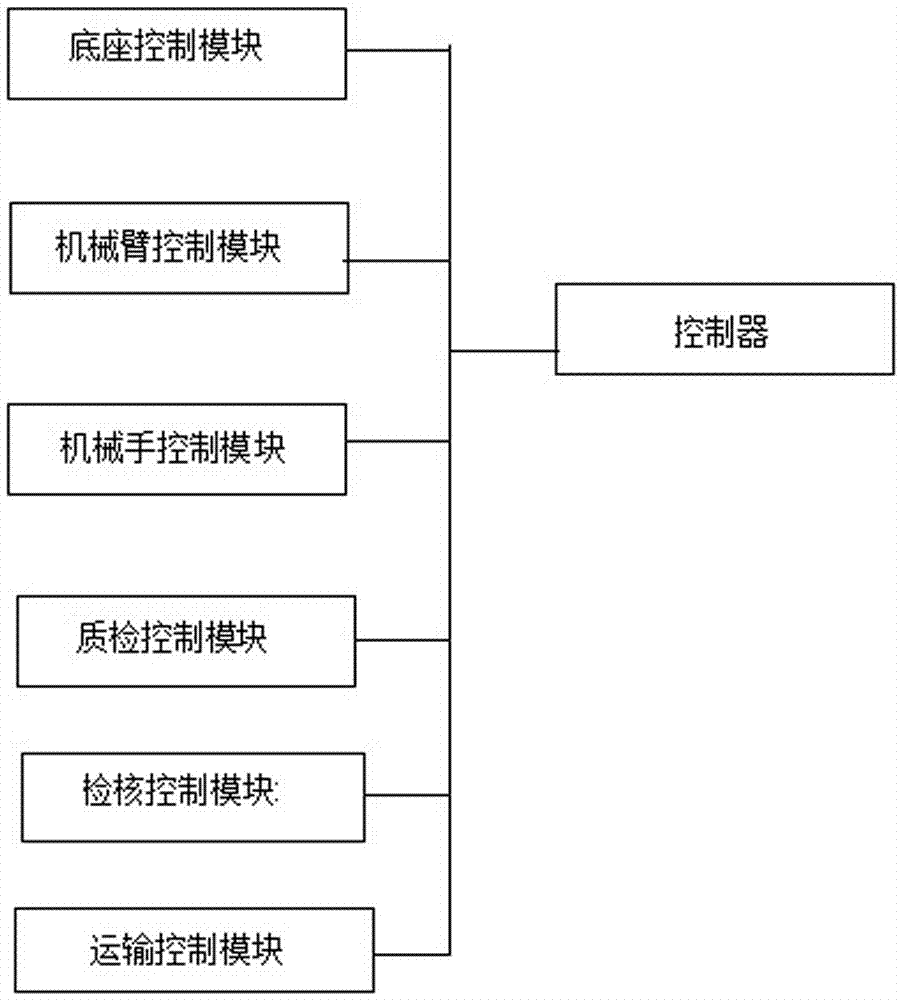

[0023] As shown in the figure, an intelligent robot with hierarchical quality inspection function includes: a base 1, a mechanical arm 2, a quality inspection mechanism 3 and a control device 4, wherein the mechanical arm 2 is arranged on the base 1, and the The quality detection mechanism 3 is located at the end of the mechanical arm 2, and the end of the mechanical arm 2 is provided with a blanking manipulator 5, the product grade database is provided in the quality detection mechanism 3, and the quality detection mechanism 3 and the lower Material manipulator 5 is all connected with control device 4.

[0024] In this embodiment, the quality inspection mechanism 3 is provided with an appearance inspection device 31 and a performance analyzer 32 for inspecting the appearance of the product, and the appearance inspection device 31 and the performance analyzer 32 are both connected to the control device 4 .

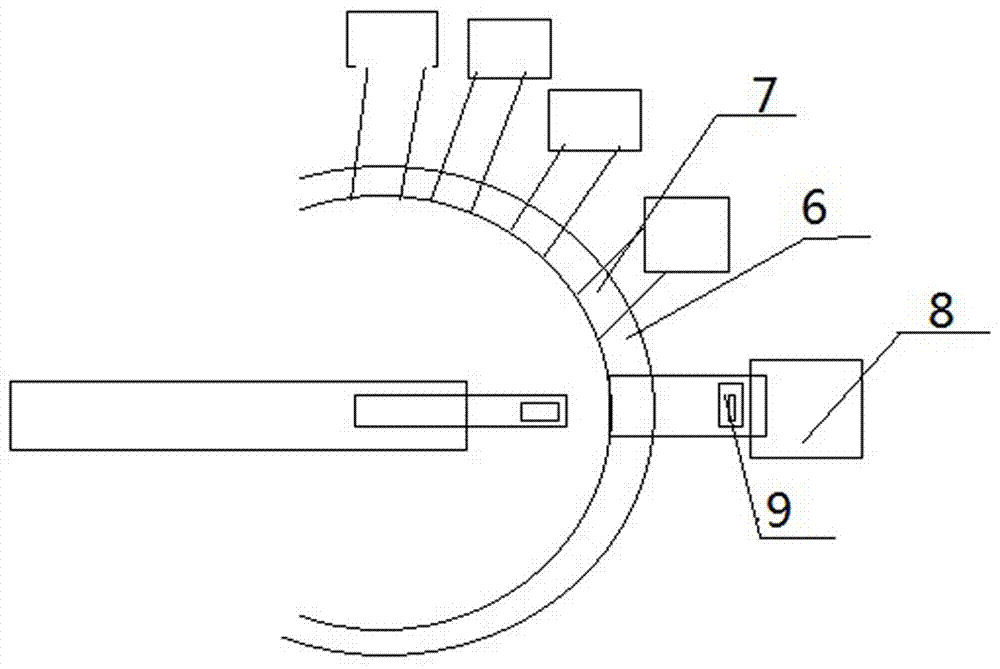

[0025] This embodiment also includes a workbench 6 , which is ring-sh...

Embodiment 2

[0032] As shown in the figure, an intelligent robot with hierarchical quality inspection function includes: a base 1, a mechanical arm 2, a quality inspection mechanism 3 and a control device 4, wherein the mechanical arm 2 is arranged on the base 1, and the The quality detection mechanism 3 is located at the end of the mechanical arm 2, and the end of the mechanical arm 2 is provided with a blanking manipulator 5, the product grade database is provided in the quality detection mechanism 3, and the quality detection mechanism 3 and the lower Material manipulator 5 is all connected with control device 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com