Low-temperature operation prevention automatic protecting method and control system for flue gas denitrification catalyst

A technology of denitrification catalyst and control system, applied in the field of automatic protection method and control system of flue gas denitrification catalyst against low temperature operation, which can solve the problems of high cost, low ultra-high temperature operation, damage of denitrification catalyst, etc., and achieve temperature and time control Accurate, automatic control is accurate, and it is not easy to control the effect of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Such as Figure 1-2 As shown, a flue gas denitrification catalyst anti-low temperature automatic protection method, including:

[0048] S1, set the following critical temperature in the DCS control system in advance:

[0049] Maximum operating temperature MXOT: the highest flue gas temperature to deactivate the denitrification catalyst;

[0050] Restoration temperature RT: the minimum flue gas temperature to regenerate the denitrification catalyst;

[0051] Minimum operating temperature MOT: the minimum flue gas temperature to deactivate the denitrification catalyst;

[0052] Minimum ammonia injection temperature MIT: the minimum flue gas temperature of the denitrification catalytic device for ammonia injection;

[0053] The maximum time of low temperature operation t2: the maximum time allowed for the denitrification catalyst to operate within MIT

[0054] Critical t1: The t1 is the shortest regeneration time required for the denitrification catalyst to rege...

Embodiment 2

[0068] Such as Figure 1-2 As shown, such as V2O5 / TiO2 as a denitration catalyst, applied in the denitration catalytic device of the present invention.

[0069] An automatic protection method against low temperature operation of a flue gas denitrification catalyst, comprising:

[0070] S1, set the following critical temperature in the DCS control system in advance:

[0071] Maximum operating temperature MXOT: The maximum flue gas temperature to deactivate the denitrification catalyst is 420°C;

[0072] Restoration temperature RT: the minimum flue gas temperature to regenerate the denitrification catalyst is 310°C;

[0073] Minimum operating temperature MOT: the minimum flue gas temperature to deactivate the denitrification catalyst is 300°C;

[0074] Minimum ammonia injection temperature MIT: The minimum flue gas temperature of the denitrification catalytic device for ammonia injection is 290°C;

[0075] Maximum time of low temperature operation t2: The maximum time allowe...

Embodiment 3

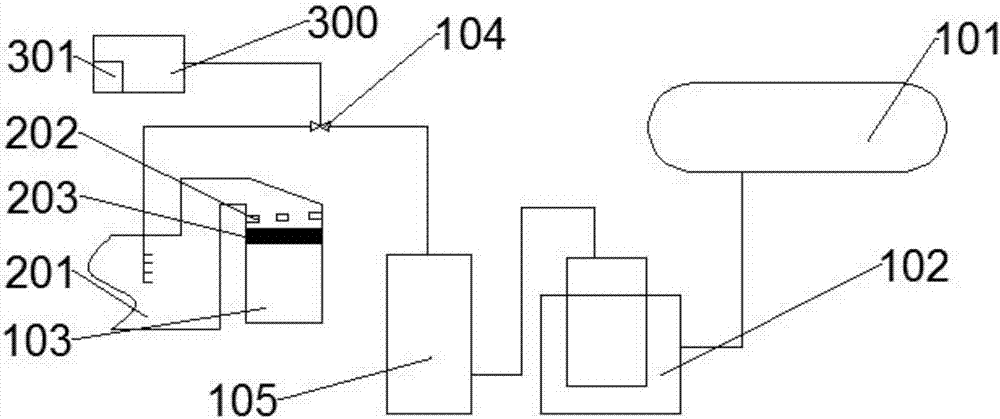

[0088] Such as figure 1 As shown, an automatic protection system applying the automatic protection method against low-temperature operation of the flue gas denitrification catalyst includes a DCS control system 300, an ammonia supply system, and a denitrification device 103. The flue 201 enters the denitration device 103, the flue 201 is connected with the ammonia supply system through the ammonia supply pipeline, the ammonia supply pipeline is provided with a valve 104, and the denitration device 103 is provided with a temperature sensor 202, the temperature sensor 202 and the DCS control system 300 Electrically connected, the DCS control system 300 is connected to the valve 104 .

[0089] The ammonia supply system includes a liquid ammonia storage tank 101, an evaporation tank 102, and a buffer tank 105. The liquid ammonia in the liquid ammonia storage tank 101 passes through the evaporation tank 102 and the buffer tank 105 in sequence and then becomes ammonia gas, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com