Weft insertion system of air-jet loom

A weft insertion system, the technology of air-jet looms, applied in the directions of looms, textiles, textiles, and papermaking, etc., can solve the problem that the weft yarn is easily disturbed by airflow, impurities or gravity, affects the quality and efficiency of weft insertion, and the predetermined weft insertion coordinates are inconsistent. Accuracy and other issues to achieve the effect of ensuring the efficiency of weft insertion, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

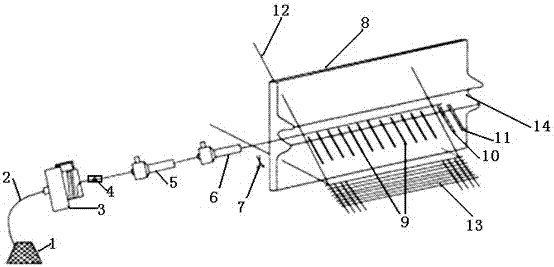

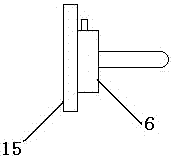

[0016] Depend on Figure 1-2 It can be seen that a weft insertion system for an air-jet loom includes a special-shaped reed 8, a fixed-length weft feeder 3, a main nozzle, an auxiliary nozzle 9, a weft detector and scissors 7, and the special-shaped reed 8 is provided with a reed groove 14, and the reed groove 14 A number of auxiliary nozzles 9 are provided in the notch of the special-shaped reed 9, and a weft detector is arranged at one end of the special-shaped reed 8 adjacent to the auxiliary nozzles 9. The other end of the special-shaped reed 8 is provided with a main nozzle, and scissors are arranged between the main nozzle and the special-shaped reed 8 7. The weft yarn 2 withdrawn from the bobbin 1 is connected to the main nozzle through the fixed-length weft feeder 3 and the yarn guide 4. The main nozzle includes a fixed main nozzle 5 and a swinging main nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com