High Power Microwave Mode Conversion Horn Antenna

A high-power microwave and mode conversion technology, applied in the field of radiation antennas, can solve the problems that the axial direction is not compact enough, and the horn antenna cannot be directly used to transmit high-power microwaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The specific design dimensions of the mode conversion lens embodiment in the high power microwave mode conversion horn antenna with a high power microwave frequency of 12 GHz (that is, the frequency of the input microwave source is 12 GHz, and the corresponding microwave wavelength is 25 mm):

[0036] The first matching layer 21 , the filling medium 23 , and the second matching layer 24 are made of epoxy resin, and the relative dielectric constant of the epoxy resin is 4. At this frequency, the semi-major axis a1 of the first elliptical cylindrical hole 221 should satisfy 3.57mm3.679mm, and the side length d of the regular hexagon in the cross section of the mode conversion unit should satisfy Select the side length d=7.56mm of the regular hexagon, and after the microwave is transmitted through the first matching layer 21, the first elliptical cylindrical hole 221 and the first transition hole 222, the microwave from the linearly polarized TE mode to the right-handed cir...

Embodiment 2

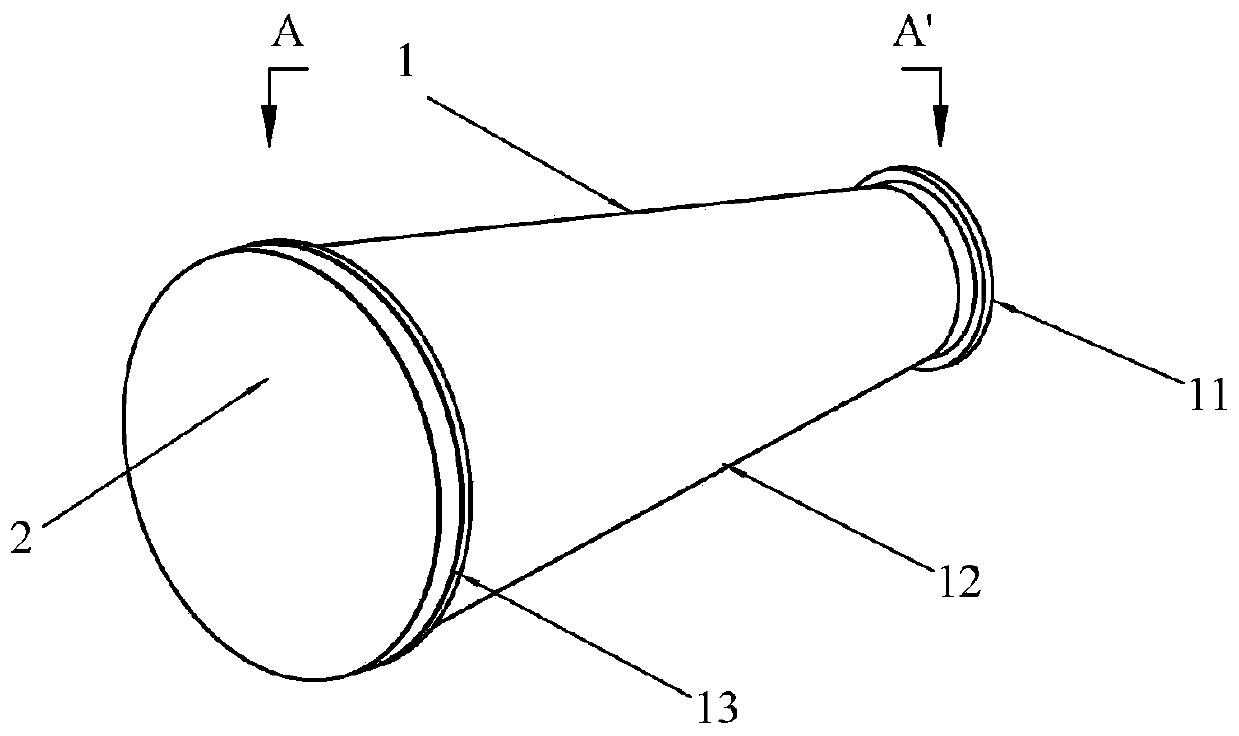

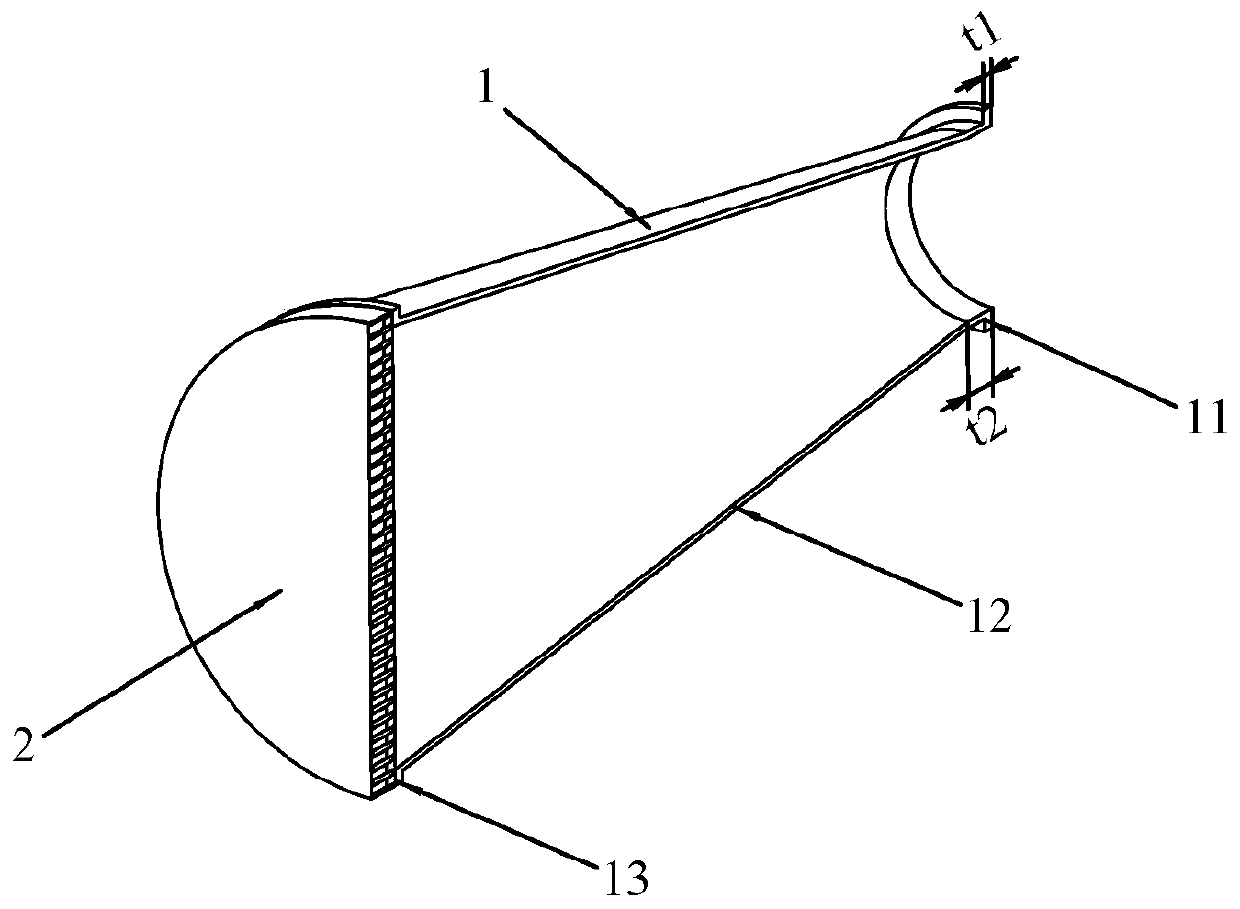

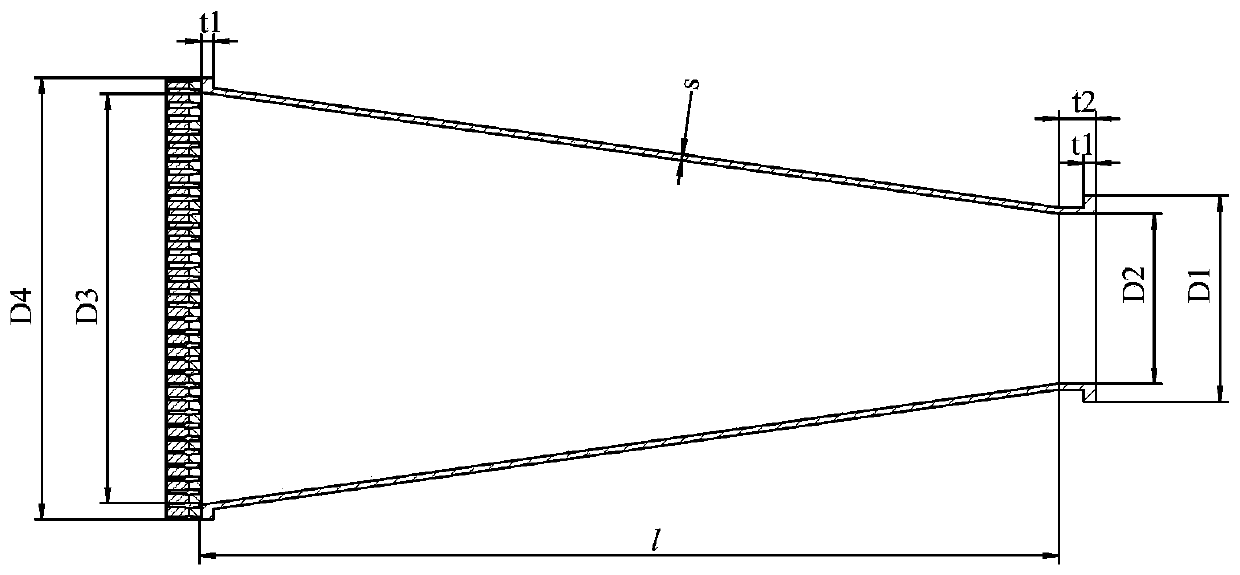

[0039] The specific design dimensions of the embodiment of the high-power microwave mode-converted horn antenna with the high-power microwave frequency of 14.2GHz (that is, the frequency of the input microwave source is 14.2GHz, and the corresponding microwave wavelength is 21.03mm):

[0040] The horn antenna 1 adopts a conical horn antenna, wherein the circular waveguide in the antenna main body 12 and the inner diameter of the conical waveguide near the microwave source end D2=140mm, the length of the circular waveguide t2=30mm, and the inner diameter of the conical waveguide away from the microwave source end D3=340mm, the axial length l=703mm; the outer diameter of the first flange 11 D1=170mm, the outer diameter of the second flange 13 D4=370mm, the thickness of the first flange 11 and the second flange 13 are both t1=10mm, the waveguide Wall thickness s=5mm; the diameters of the first matching layer 21, the second matching layer 24 and the metal disc 22 are equal to the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com