An anti-return light all-fiber device

A return light and all-fiber technology, which is applied to laser components, lasers, electrical components, etc., can solve problems such as increasing heat generation, damaging optical fiber devices, and destroying resonators, and achieves easy integration, high-efficiency stripping, and industrialization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

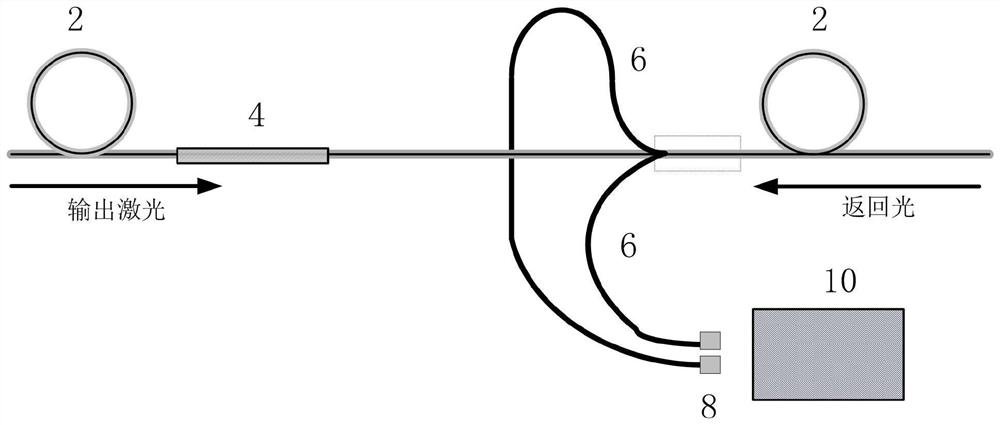

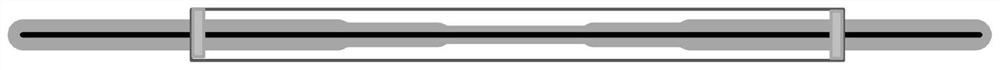

[0029] refer to figure 1 As shown, this embodiment discloses an anti-return light all-fiber device, including an energy transmission fiber 2, a cladding light filter 4, and a beam splitting fiber 6. Along the output laser direction of the energy transmission fiber 2, the above cladding light The filter 4 and the splitting optical fiber 6 are arranged in sequence.

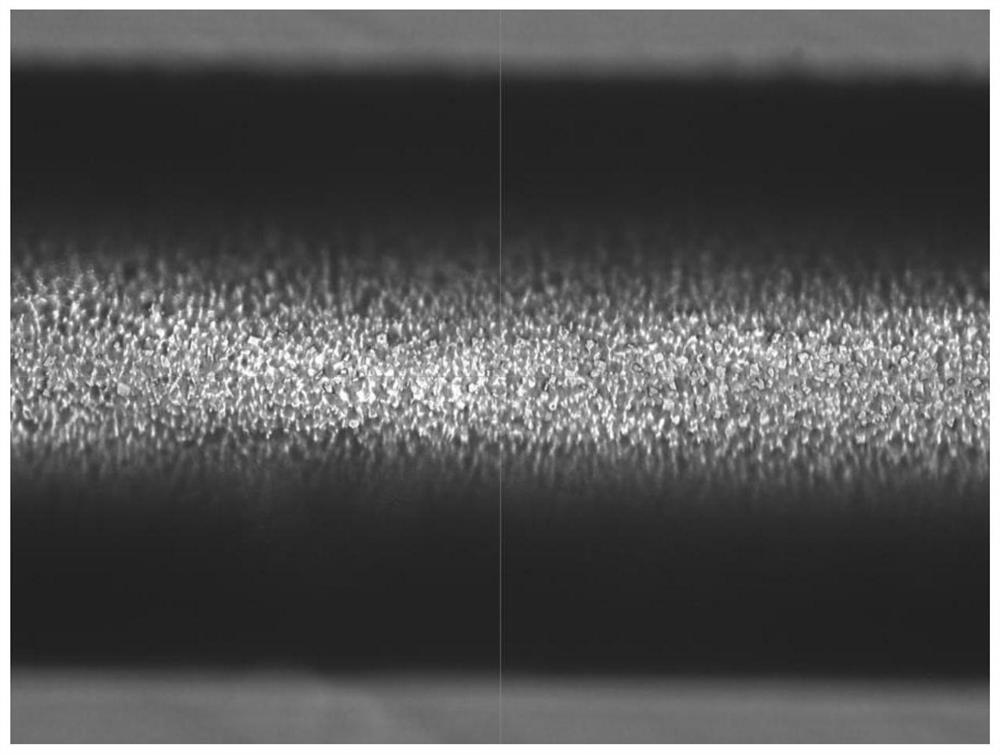

[0030] The above-mentioned energy transmission fiber 2 is used in high-power fiber laser equipment, preferably a double-clad fiber or a triple-clad fiber. Energy confinement is transmitted in the core of the energy-transmitting optical fiber 2 . Commonly used double-clad models are 20 / 400μm, 20 / 250μm, 25 / 250μm, 25 / 400μm, 30 / 250μm, 30 / 400μm, 30 / 600μm, 50 / 360μm, 50 / 400μm, 100 / 330μm, 100 / 360μm , 400 / 480μm and other specifications and models. Commonly used three-clad models include 50 / 70 / 360μm, 50 / 70 / 480μm, 100 / 120 / 360μm, 100 / 130 / 660μm and other specifications.

[0031] The splitting fiber 6 is coupled to the claddi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com