Graphene modified spandex fiber as well as preparation method and application thereof

A technology of graphene modification and spandex fiber, which is applied in the direction of fiber chemical characteristics, rayon manufacturing, conductive/antistatic filament manufacturing, etc., can solve the problem of low elongation at break of spandex fiber, achieve saving raw material components, improve Comprehensive performance and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

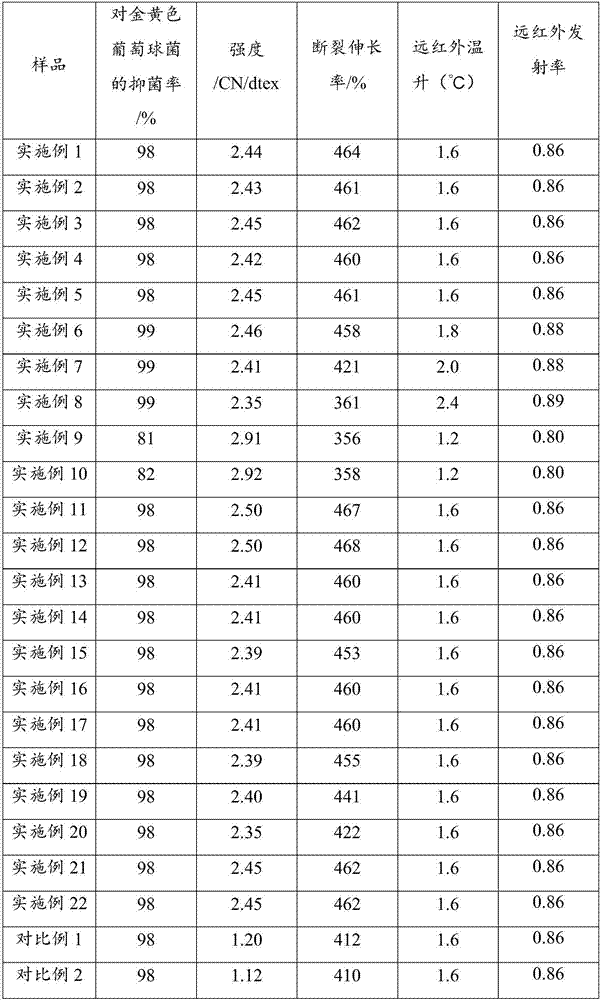

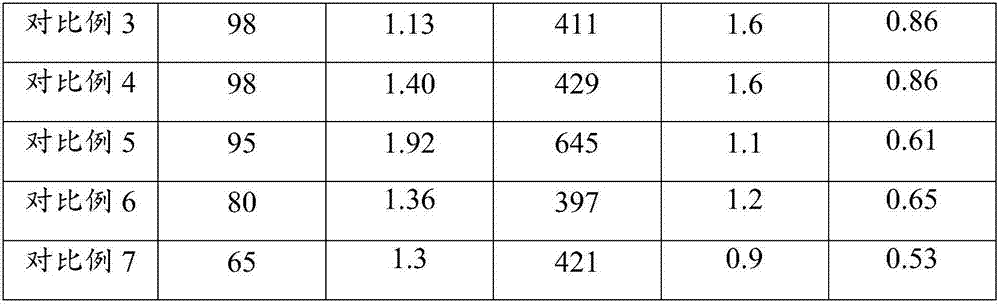

Examples

Embodiment 1

[0064] 1. Preparation of chain extension solution: Mix 2 g of graphene C and 20 g of ethylenediamine in DMF to obtain a chain extension solution with a total mass percentage concentration of graphene C and ethylenediamine of 4.0%.

[0065] 2. Preparation of prepolymer: Toluene diisocyanate and polytetrahydrofuran diol (PTMG-2000) are mixed at a molar ratio of 1.5:1, and the total mass of the two is 2kg, then 1g of graphene C is added, and then heated to 60°C Next, pre-polymerization is performed. After the pre-polymerization is completed, DMAC solvent is added to the pre-polymer to prepare a pre-polymer solution with a concentration of 40% by mass of the pre-polymer.

[0066] 3. the chain extension solution in step 1 and the prepolymer solution in step 2 are mixed, carry out chain extension reaction, make fiber-forming polymer solution, its mass percent concentration is 33% (being the solid content of fiber-forming polymer ).

[0067] 4. Preparation of additive slurry: 7 g of...

Embodiment 2

[0070] The difference from Example 1 is that the ratio of graphene C added in three steps is different, as follows:

[0071] 1. Preparation of chain extension solution: Mix 4 g of graphene C and 20 g of ethylenediamine in DMF to obtain a chain extension solution with a total mass percentage concentration of graphene C and ethylenediamine of 4.0%.

[0072] 2. Preparation of prepolymer: Mix toluene diisocyanate and polytetrahydrofuran diol (PTMG-2000) at a molar ratio of 1.5:1, and the total mass of the two is 2kg, then add 3g of graphene C, and then heat to 60°C Next, pre-polymerization is performed. After the pre-polymerization is completed, DMAC solvent is added to the prepolymer to prepare a prepolymer solution with a concentration of 40% by mass.

[0073] 3. the chain extension solution in step 1 and the prepolymer solution in step 2 are mixed, carry out chain extension reaction, make fiber-forming polymer solution, its mass percent concentration is 33% (being the solid con...

Embodiment 3

[0077] The difference from Example 1 is that the ratio of graphene C added in three steps is different, as follows:

[0078] 1. Preparation of chain extension solution: Mix 3 g of graphene C and 20 g of ethylenediamine in DMF to obtain a chain extension solution with a total mass percentage concentration of graphene C and ethylenediamine of 4.0%.

[0079]2. Preparation of prepolymer: Mix toluene diisocyanate and polytetrahydrofuran diol (PTMG-2000) at a molar ratio of 1.5:1, and the total mass of the two is 2kg, then add 2g of graphene C, and then heat to 60°C Next, pre-polymerization is performed. After the pre-polymerization is completed, DMAC solvent is added to the prepolymer to prepare a prepolymer solution with a concentration of 40% by mass.

[0080] 3. the chain extension solution in step 1 and the prepolymer solution in step 2 are mixed, carry out chain extension reaction, make fiber-forming polymer solution, its mass percent concentration is 33% (being the solid cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com