Negative electrode for lithium metal battery and lithium metal battery comprising the same

A technology for lithium metal electrodes and lithium metal batteries, which is applied in the field of negative electrodes for lithium metal batteries and lithium metal batteries including them, and can solve problems such as reduced lifespan and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

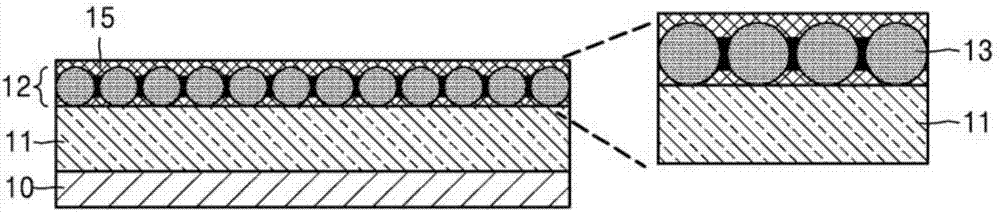

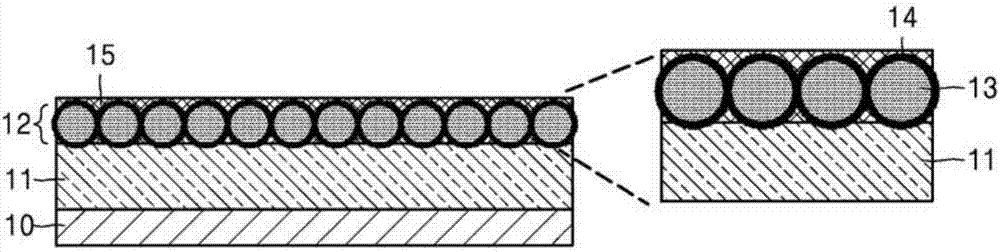

[0302] Embodiment 1: the manufacture of negative electrode

[0303] Poly(styrene-b-divinylbenzene) block copolymer microspheres (with an average particle diameter of about 3 μm, EPR-PSD-3, available from EPRUI Nanoparticles & Microparticles Co., Ltd.) were added to anhydrous tetrahydrofuran A mixture comprising 5% by weight of block copolymer is obtained.

[0304] The block copolymers in the mixture comprising block copolymers comprise polystyrene blocks and polydivinylbenzene blocks in a mixing ratio of about 9:1 by weight, and the poly(styrene The -b-divinylbenzene) block copolymer has a weight average molecular weight of about 100,000 Daltons.

[0305] Lithium bis(fluorosulfonyl)imide (LiFSI, LiN(SO 2 F) 2 ) is added to the mixture comprising the block copolymer to obtain a protective layer forming composition. The amount of LiFSI is about 30 parts by weight based on 100 parts by weight of the poly(styrene-b-divinylbenzene) copolymer.

[0306] The composition for for...

Embodiment 2 and 3

[0309] Examples 2 and 3: Manufacture of Negative Electrode

[0310] Negative electrodes were fabricated in the same manner as in Example 1, except that the thicknesses of the protective layers were changed to about 1 μm and about 8 μm, respectively.

Embodiment 4

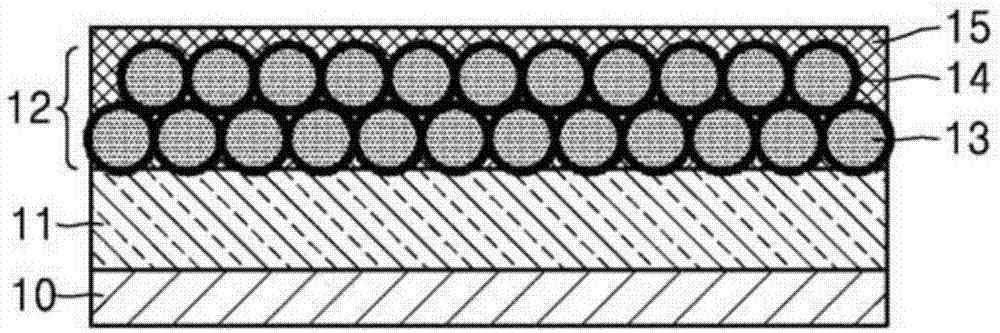

[0311] Embodiment 4: the manufacture of negative electrode and lithium metal battery

[0312] A negative electrode was fabricated in the same manner as in Example 1. The negative electrode has a protective layer comprising microspheres on a lithium metal thin film and a cross-linked material of DEGDA in the interstices between the microspheres. The amount of crosslinking material of DEGDA is about 20 parts by weight based on 100 parts by weight of the poly(styrene-b-divinylbenzene) block copolymer microspheres.

[0313] LiCoO 2 , a conductive agent (Super-P; Timcal Ltd.), polyvinylidene fluoride (PVdF), and N-methylpyrrolidone were mixed together to obtain a composition for forming a positive electrode active material layer. LiCoO in the composition for forming the positive electrode active material layer 2 , conductive agent, and PVdF in a mixing weight ratio of about 97:1.5:1.5. Relative to 97g of LiCoO 2 , the amount of N-methylpyrrolidone was about 137 g.

[0314] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com