Pipe network fault hydraulic monitoring experimental system and fault identification achieving method thereof

A hydraulic monitoring and experimental system technology, applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of limited feasibility, slow opening and closing speed, burst pipes, etc., to overcome high pressure water hammer Fluctuation, simple composition, overcoming uncontrollable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0070] The invention is applied to early warning, monitoring and fast and accurate positioning of pipeline water transmission projects and water transmission and distribution network failures (including leakage, local blockage, etc.), and is used to support and verify the digital management platform of water supply network (including health evaluation, determination of intelligent management, etc.) program equipment, techniques and methods).

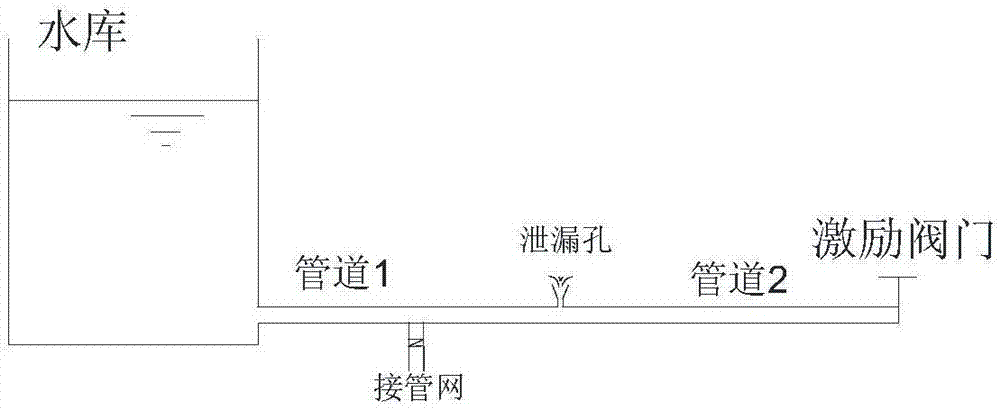

[0071] Such as image 3 As shown, a kind of pipe network failure hydraulic monitoring experiment system provided by the present invention comprises:

[0072] Adjustable high-level water tank (made of steel) 1 is used to simulate different water supply pressures and flows in the monitored water transfer project, municipal water supply pipe network reservoir or upstream, and has a built-in horizontal wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com