Explosion-proof type mechanical switching-off device for gas emergency switching off

An explosion-proof, cut-off technology, applied in mechanical equipment, engine components, valve operation/release devices, etc., can solve the problems of complex processing and installation, hidden safety hazards, inconvenient operation, etc., to reduce the difficulty of manufacturing and installation, The effect of simplifying the structure and increasing the safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is described in detail:

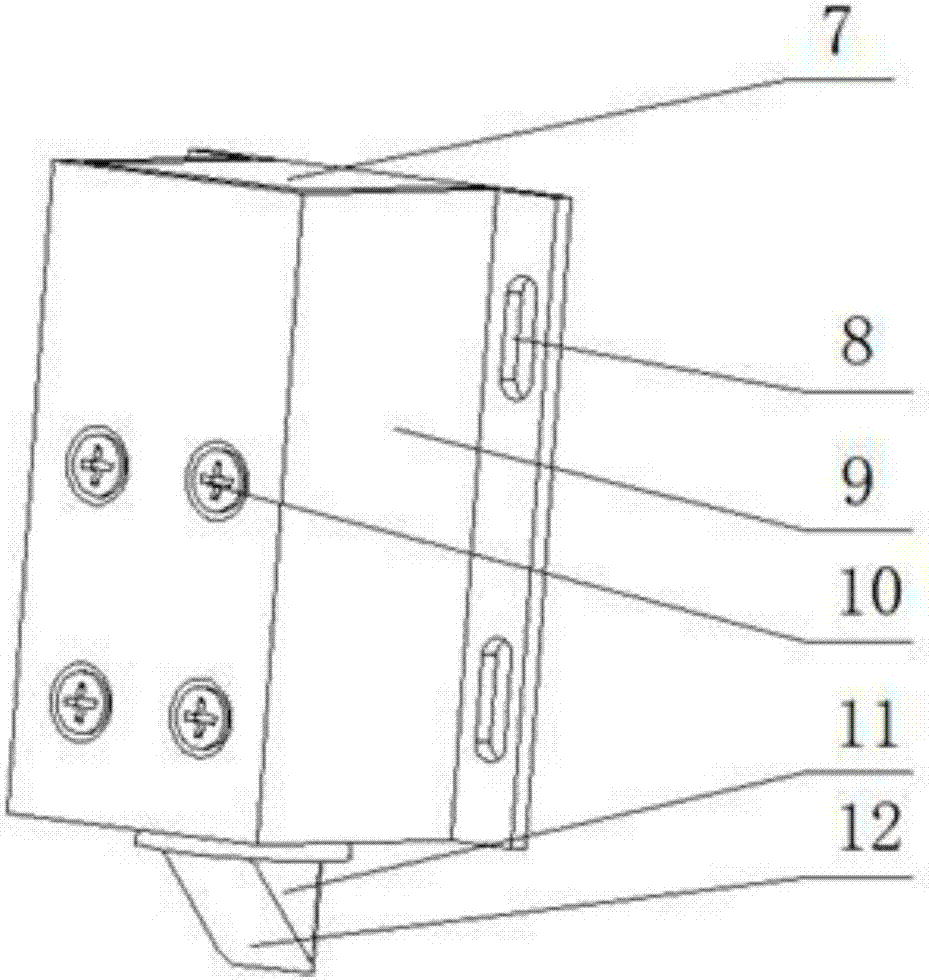

[0014] Such as figure 2 Shown is the structure of the electromagnetic lock in the explosion-proof gas emergency cut-off mechanical disconnector. The electromagnetic lock includes a push-pull electromagnet 7 and a bracket 9 . The coil in the push-pull electromagnet is encapsulated, and its moving iron core and the lock head 11 are welded as a whole. The shape of the end of the lock head is a slope 11 . The bracket 9 is a "several"-shaped sheet metal, and its two sides are provided with strip holes 8. Connect with countersunk head screw 10 between push-pull electromagnet 7 and support 9.

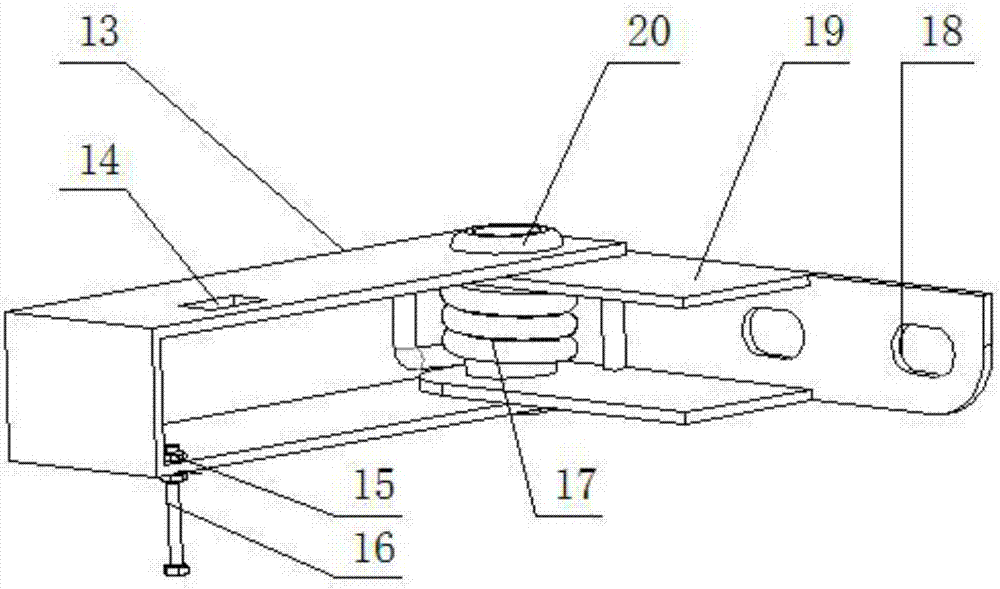

[0015] Such as image 3 Shown is a torsion spring clip in a mechanical disconnector for flameproof gas emergency shutoff. The torsion spring clip is made of outer clip 13, inner clip 19, torsion spring 17, connecting shaft 20, support screw 16 and two fixing nuts 15. The connecting sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com